K

u

n

st

st

o

ffs

c

h

w

e

iß

te

c

h

n

ik

W

e

ld

in

g

T

a

b

le

s

C

h

a

p

te

r 6

20

1,5

21

25

29

33

37

41

45

49

53

57

61

65

69

73

77

81

85

89

19

1

20

23

27

31

35

39

42

46

50

54

58

61

65

69

73

77

80

84

18

1

19

22

26

29

33

37

40

44

47

51

55

58

62

65

69

73

76

80

17

1

18

21

24

28

31

35

38

41

45

48

52

55

58

62

65

69

72

75

16

1

17

20

23

26

29

33

36

39

42

45

49

52

55

58

61

65

68

71

15

1

16

19

22

25

28

31

34

37

40

43

46

49

52

55

58

61

64

67

14

1

15

17

20

23

26

29

31

34

37

40

43

45

48

51

54

57

59

62

13

1

14

16

19

21

24

27

29

32

34

37

40

42

45

47

50

53

55

58

12

1

13

15

17

20

22

25

27

29

32

34

37

39

41

44

46

49

51

53

11

1

12

14

16

18

20

23

25

27

29

31

34

36

38

40

42

45

47

49

10

1

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

41

43

45

9

1

10

11

13

15

17

19

20

22

24

26

28

29

31

33

35

37

38

40

9

1

10

11

13

15

17

19

20

22

24

26

28

29

31

33

35

37

38

40

8

1

9

10

12

13

15

17

18

20

21

23

25

26

28

29

31

33

34

36

7

0,5

8

9

10

12

13

15

16

17

19

20

22

23

24

26

27

29

30

31

6

0,5

7

8

9

10

11

13

14

15

16

17

19

20

21

22

23

25

26

27

5

0,5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

4

0,5

5

5

6

7

8

9

9

10

11

12

13

13

14

15

16

17

17

18

3

0,5

4

4

5

5

6

7

7

8

8

9

10

10

11

11

12

13

13

14

2

0,5

3

3

3

4

4

5

5

5

6

6

7

7

7

8

8

9

9

9

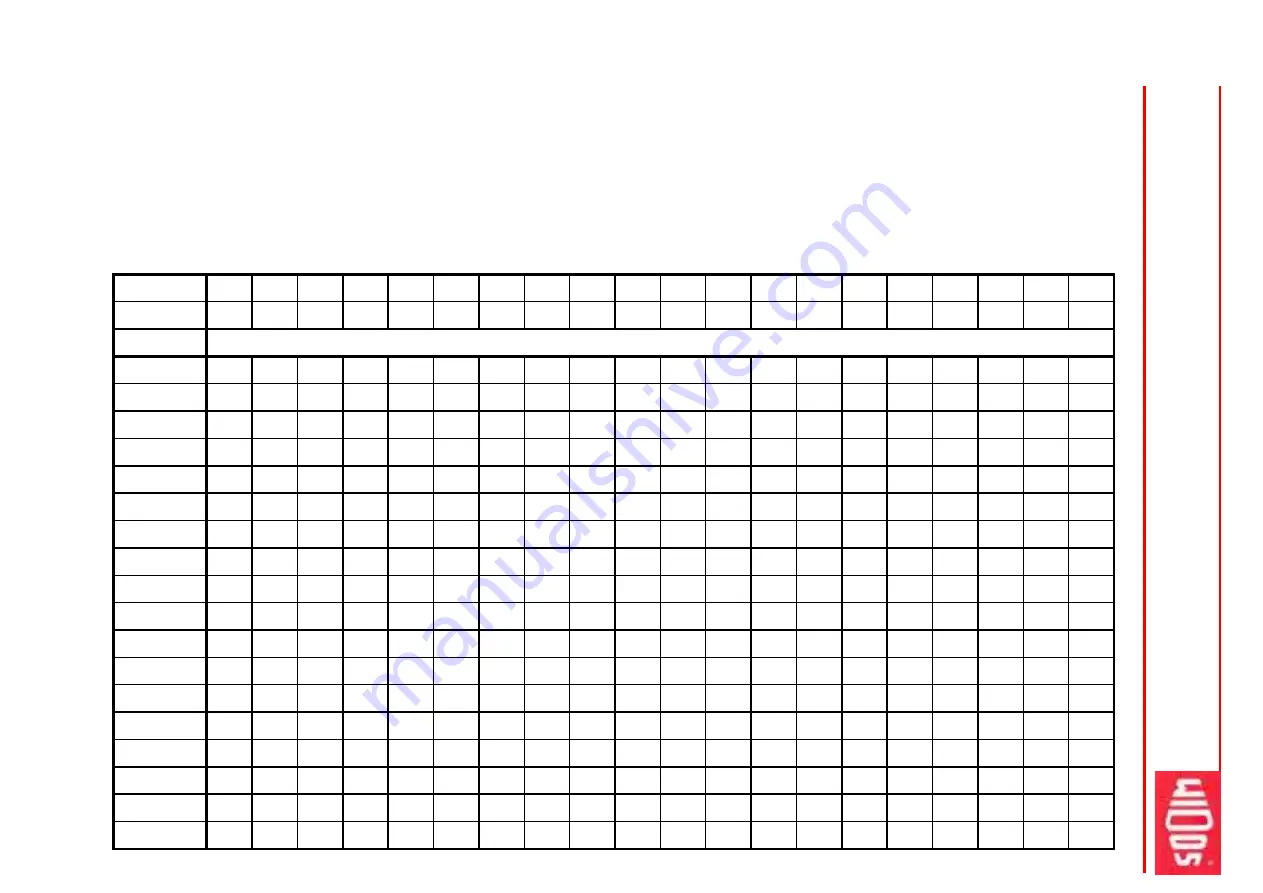

Thickness

Bead hight

Lenght

100

120

140

160

180

200

220

240

260

280

300

320

340

360

380

400

420

440

J o i n i n g f o r c e

[kp]

For the given adjusting and welding force the movement force of the welding slide has to be added! 1 kp = 10 N

Table for PP

Heating up time =

15 x

wall thickness [sec], for 2 - 4 mm wall thickness; and

16

x

wall thickness [sec], for 5 - 10 mm wall thickness

Cooling down time under joining force =

2,0 x

wall thickness [min], for 2 - 4 mm; and

1,75 x

wall thickness [min] for >4 - 10 mm wall thi

The standard value for heating element temperature is 210° C ± 10 °C, for

smaller

wall thickness higher temperatures have to be realized.

0

3

.0

3

.2

0

0

9

W

o

rk

in

g

In

s

tru

c

tio

n

s

W

ID

O

S

P

S

M

1

5

P

a

g

e

2

3

/

1

o

f 3

3