17

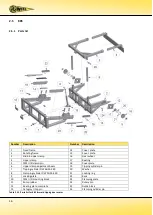

2.5.2 Commissioning the K80 and K85 box rotators

Different methods are used to fit the mounting blocks and clamping plate, depending on the type of fork

carrier used. These are described below.

FEM II fork carrier

1.

Loosen the FEM II/III mounting block bolts and remove the mounting blocks.

2.

Reattach the mounting blocks using the bolts, so that the FEM II is underneath. Tighten the bolts securely

(200Nm).

3.

Remove the clamping plate with the pins and retaining clips.

4.

Remove the forks from the forklift truck or forklift mast.

5.

Make sure the fork carrier is straight and clean.

6.

Place the box rotator on the forklift truck or lifting mast fork carrier, depending on the box dimensions.

7.

Make sure the locking cam slots into the recess in the centre of the fork carrier. If no recess is available:

a)

Grind such a recess; or

b)

Grind the locking cam from the box rotator and attach a sound locking cam on the spot of an existing recess

in the fork carrier. In doing so, make sure the box rotator sits secure in the centre in front of the fork carrier,

so it is unable to slide sideways

8.

Attach the clamping plate to the fork carrier profile with the FEM II profile above, using the 9x11 pins and

retaining clips.

9.

Check to make sure the hydraulic hoses are clean before connecting them to the rapid-action couplings to

prevent any debris from entering the hydraulics of the machine.

10.

Depending on the model, the following hydraulic hoses are connected:

a)

Electrically controlled switching valve

Connect the hydraulic supply/discharge hoses to the dual-action connection on the fork carrier.

Install the supplied switch so that the machine driver is able to operate it from his driving position and

cannot confuse it with other controls.

For a safe working environment, avoid situations such as inadvertently starting the machine or not being

able to control it.

Keep an eye on the correct voltage of the lifting device and the valve. The voltage is shown on the coil.

Attach a twin core cable in accordance with the circuit diagram. Include a warning light, fuse and/or plug

socket in the circuit if required.

b)

Four-hose connection

Connect the two pairs of hydraulic supply/discharge hoses to the dual-action connection on the fork carrier.

FEM III fork carrier

1.

See FEM II fork carrier, however the mounting blocks must be fitted with the FEM III profile below, while the

clamping plate should have its FEM III profile above.