9

2.

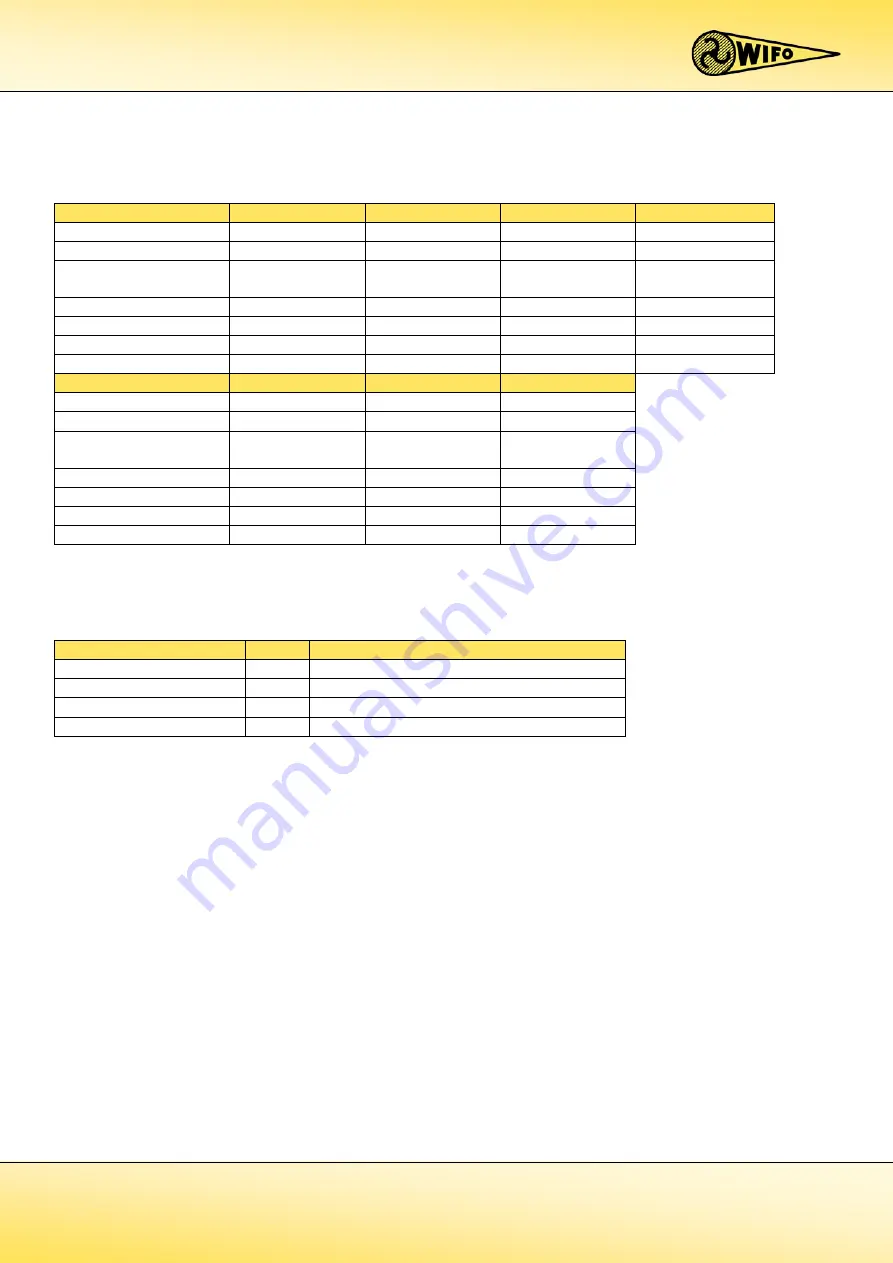

Technical data

2.1

General technical data

The K90 forward tipping box rotator is suitable for attachment to FEM II (407mm) and FEM III (508mm) fork carriers.

Type

Letter

Description

K90

E

Electrically controlled switching valve

S

4-hose connection

V

Sequence valves

Table 2.1.2-Description data on model plate

The box rotators are equipped with an electric or hydraulic limit switch to prevent unintended opening of the upper

clamp during tipping. The upper clamp can only be opened when the tipping frame is horizontal.

Type

K90-1200

K90-1400

K90-1600

K90-1800

Max. carrying capacity

2500 kg

2500 kg

2500 kg

2500 kg

Weight

845 kg

870 kg

895 kg

920 kg

Working pressure

18 Mpa - 23 Mpa

(180 bar - 230 bar)

18 Mpa - 23 Mpa

(180 bar - 230 bar)

18 Mpa - 23 Mpa

(180 bar - 230 bar)

18 Mpa - 23 Mpa

(180 bar - 230 bar)

Centre of gravity

530 mm

530 mm

530 mm

530 mm

Frontal extension length

460 mm

460 mm

460 mm

460 mm

Transport width

1620 mm

1820 mm

2020 mm

2220 mm

Tipping angle

180°

180°

180°

180°

Type

K90-2000

K90-2240

K90-2400

Max. carrying capacity

2500 kg

2500 kg

2500 kg

Weight

945 kg

970 kg

1065 kg

Working pressure

18 Mpa - 23 Mpa

(180 bar - 230 bar)

18 Mpa - 23 Mpa

(180 bar - 230 bar)

18 Mpa - 23 Mpa

(180 bar - 230 bar)

Centre of gravity

530 mm

530 mm

530 mm

Frontal extension length

460 mm

460 mm

460 mm

Transport width

2420 mm

2660 mm

2820 mm

Tipping angle

180°

180°

180°

Table 2.1.1-K90 forward tipping box rotator