25

WIKA operating instructions process pressure transducer, model CPT6020

0020507001F 05/2019 EN

EN

7.2.2 Environment

For maximum accuracy, allow the CPT6020 to warm up a minimum of 15 minutes in ambient temperature within the compensated

range prior to a calibration. In addition, the instrument should be at rest on a stable platform that is free of excessive vibration,

shock and with minimal temperature change.

7.2.3 Pressure Standards

Mensor recommends the use of appropriately accurate primary pressure standards when calibrating this instrument. Such

standards should be sufficient so that when the techniques of the ISO Guide to the Expression of Uncertainty in Measurement

(GUM) are applied, the instrument meets its accuracy statements as required by ISO/IEC 17025:2005, or other applicable

standards.

7.2.4 Media

The recommended calibration medium is dry nitrogen or clean dry instrument air. For ranges above 5 psi any liquid media

compatible with 316L SS is acceptable. A reference height variation between the standard and the CPT6020 can cause errors. A

calculation should be made to compensate for this difference.

7.2.5 Setup

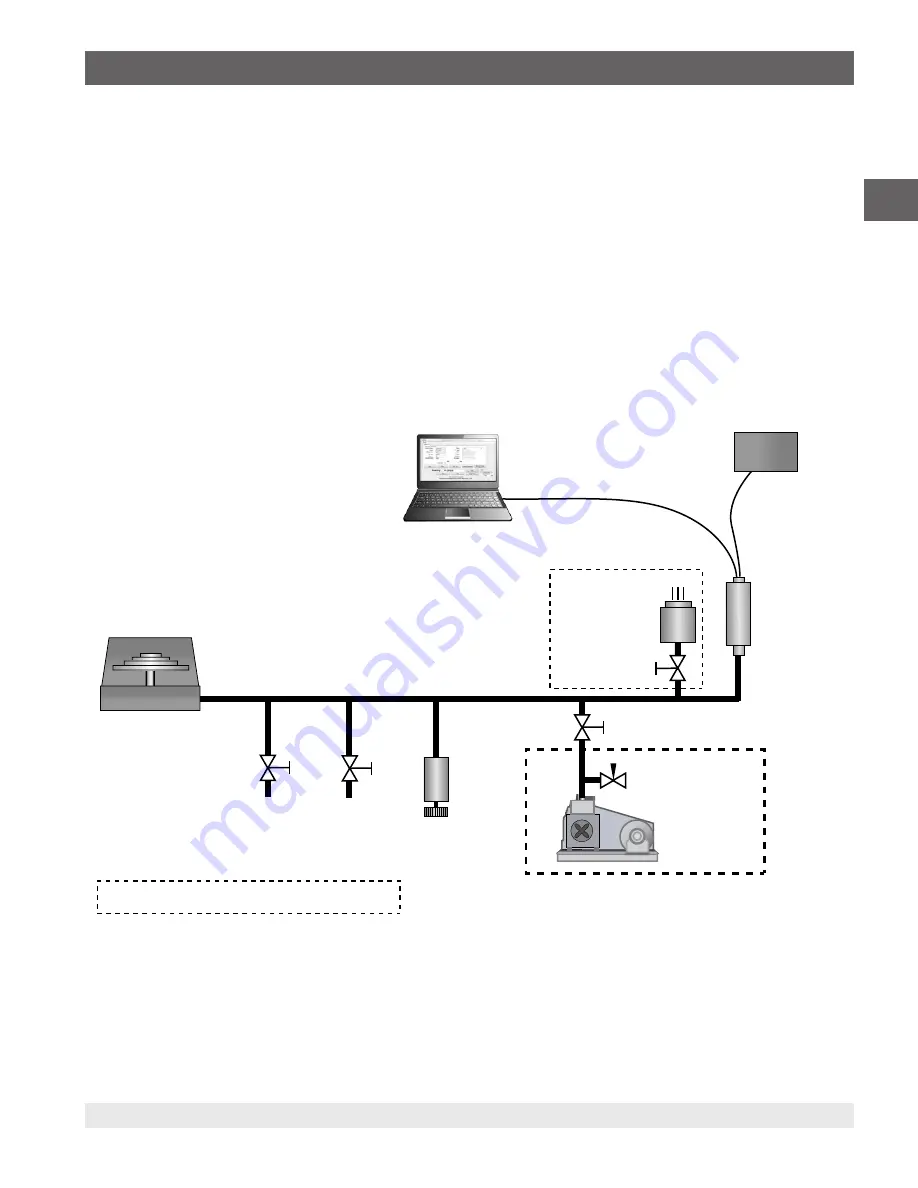

The schematic in Figure 7.2.5 shows a typical setup used to calibrate the CPT6020

.

Deadweight

Tester or

Primary

Standard

Power

Supply

Absolute

Diaphragm

Capacitance

Gauge

Transducer

Under Test

Vent

Supply

P - V

Controller

Vacuum

Pump

Communication

Objects in the dashed preimeter are only needed

for sub atmoshheric pressure points.

Needle

Valve

Figure 7.2.5 - Calibration Setup

When calibrating absolute transducers and approaching very low absolute pressures, you must use a needle valve or controlled

leak to maintain a small pressure (600 mTorr, 80 Pa recommended) throughout the system. If you try to run calibration points

below that pressure, the system will have significant pressure gradients in it unless left to stabilize for an extended period of time.

Maintenance and Recalibration