39

8 Maintenance and fault rectification

WIKA Operating Instructions - Process pressure transmitter IPT-1*

8 Maintenance and fault rectification

8.1 Maintenance

If the instrument is used properly, no special maintenance is required

in normal operation.

In some applications, product buildup on the diaphragm can influence

the measuring result. Depending on the sensor and application, take

precautions to ensure that heavy buildup, and especially a hardening

thereof, is avoided.

The diaphragm should be cleaned if necessary. For this reason, the

resistance of the materials to cleaning processes must be ensured.

The large variety of chemical seal applications makes special clean-

ing instructions for each application necessary. Please contact the

agency serving you.

Caution:

On instruments with a chemical seal, never clean the separating

diaphragm mechanically with hard objects, such as tools! This can

damage the diaphragm and lead to filling oil leaks.

8.2 Rectify faults

The operator of the system is responsible for taking suitable meas-

ures to rectify faults.

IPT-1* offers maximum reliability. Nevertheless, faults can occur dur

-

ing operation. These may be caused by the following, e.g.:

•

Sensor

•

Process

•

Voltage supply

•

Signal processing

The first measures to be taken are to check the output signals as well

as to evaluate the error messages via the display and adjustment

module. The procedure is described below. Further comprehensive

diagnostics can be carried out on a PC with the software PACTware

and the suitable DTM. In many cases, the causes can be determined

and the faults rectified this way.

Connect a multimeter in the suitable measuring range according to

the wiring plan.

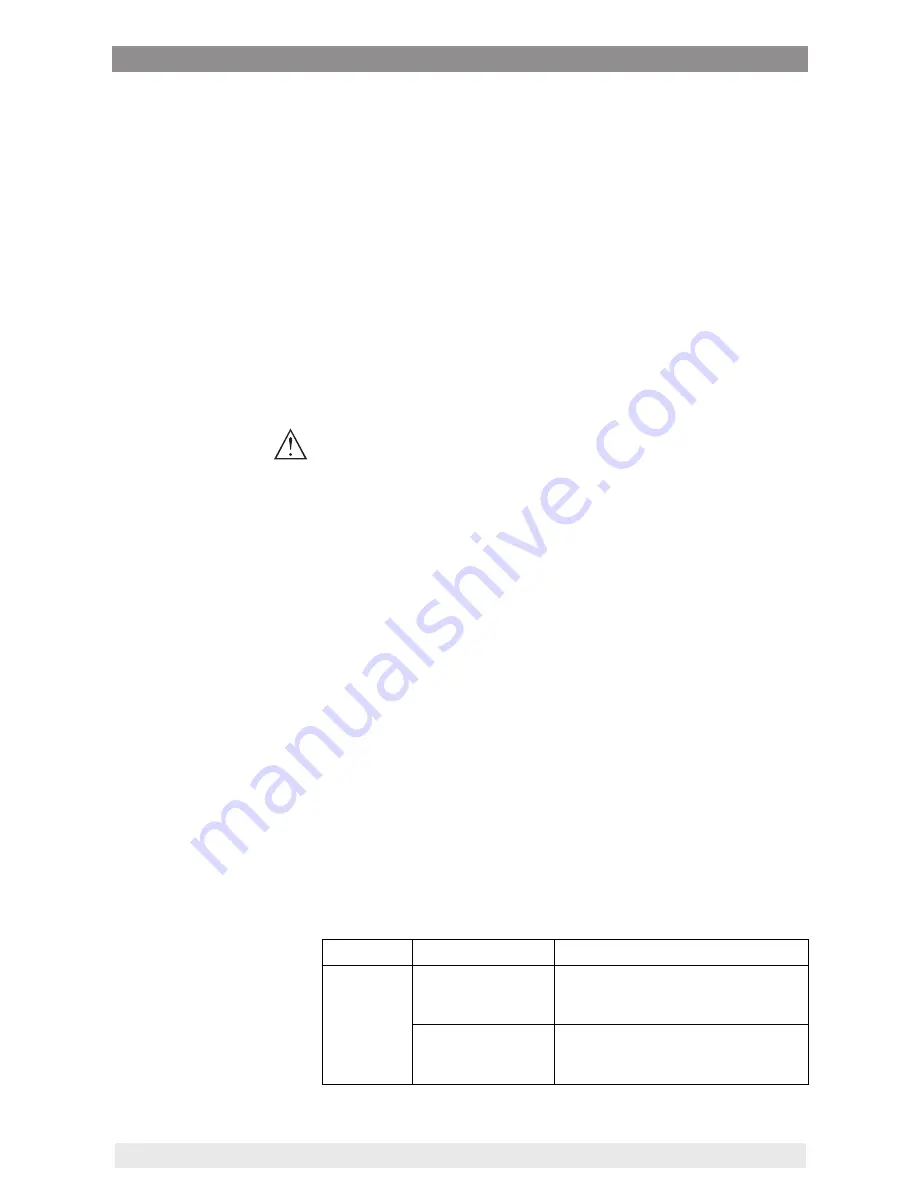

Error code Cause

Rectification

4 … 20 mA

signal not

stable

Level fluctuations

– Set the integration time via the

display and adjustment module or

PACTware

No atmospheric pres

-

sure compensation

– Check the pressure compensation

in the housing and clean the filter

element, if necessary

Maintenance

Cleaning

Reaction when malfunc-

tion occurs

Causes of malfunction

Fault rectification

Check the 4 … 20 mA

signal