2.3 Special hazards

WARNING!

Residual media in the dismounted instrument

can result in a risk to persons, the environment

and equipment.

Take sufficient precautionary measures.

2.4 Labelling, safety marking

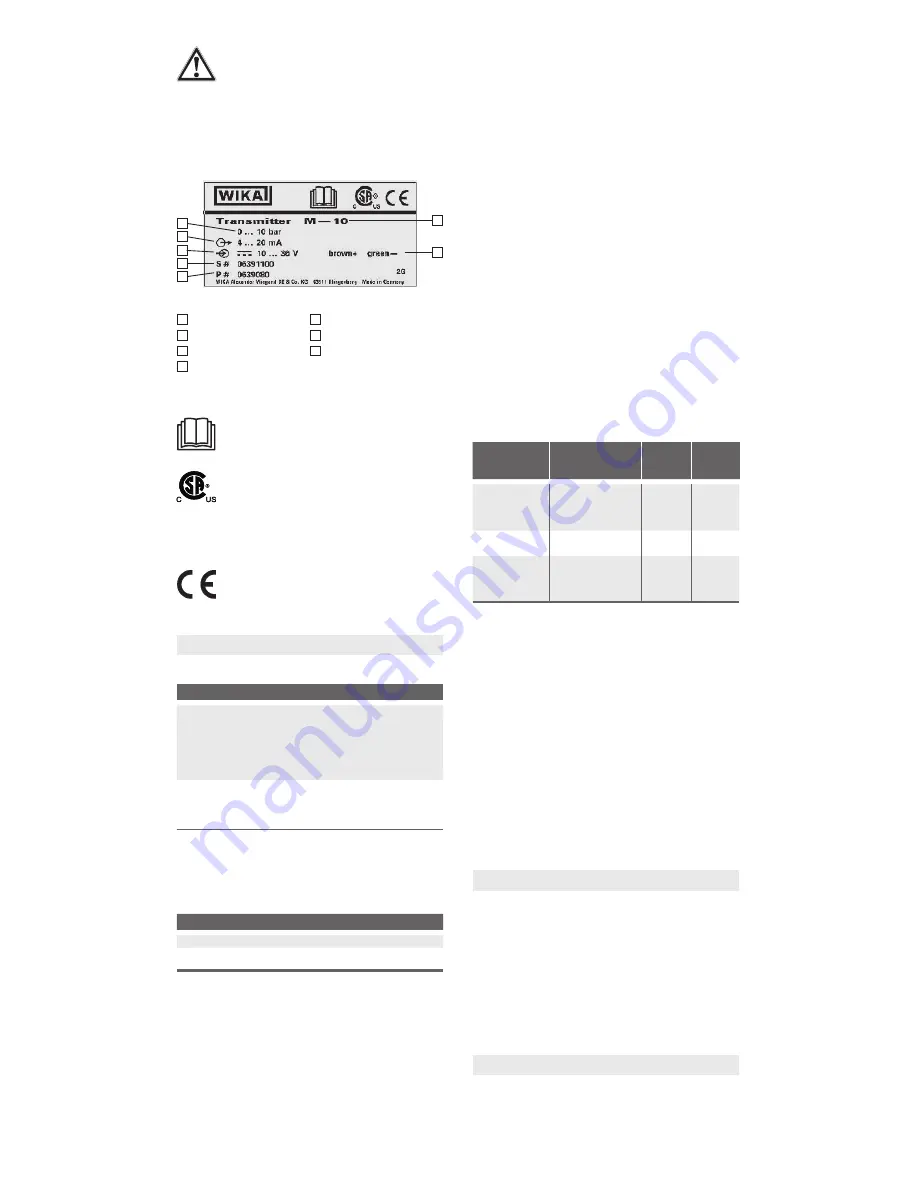

Product label

1

Measuring range

5

P# product number

2

Output signal

6

Model

3

Power supply

7

Pin assignment

4

S# serial number

Explanation of symbols

Before mounting and commissioning the

instrument, ensure you read the operating

instructions!

CSA, Canadian Standard Association

®

The instrument was inspected and certified

by CSA International. Instruments bearing this

mark comply with the applicable Canadian and

American standards on safety (including explo-

sion protection).

CE, Communauté Européenne

Instruments bearing this mark comply with the

relevant European directives.

3. Specifications

3.1 Measuring ranges

Relative pressure

bar Measuring range

0 ... 6

1)

0 ... 10

1)

0 ... 16

1)

0 ... 25

Overload safty

20

20

32

50

Measuring range

0 ... 40

0 ... 60

0 ... 100

0 ... 160

Overload safty

80

120

200

320

Measuring range

0 ... 250

0 ... 400

0 ... 600

0 ... 1,000

1)

Overload safty

500

800

1,200

1,500

psi

Measuring range

0 ... 500

0 ... 1,000

0 ... 3,000

0 ... 5,000

Overload safty

1,000

2,000

6,000

10,000

Measuring range

0 ... 10,000 0 ... 15,000

Overload safty

20,000

20,000

1) Only for model M-10

Vacuum tightness

Yes

3.2 Output signal

Signal type

Signal

Current (2-wire)

4 ... 20 mA

Voltage (3-wire)

DC 1 ... 5 V

DC 0.1 ... 10 V

Load in Ω

4 ... 20 mA:

≤ (power supply - 10 V) / 0.02 A

DC 1 ... 5 V:

> 10k

DC 0.1 ... 10 V:

> 20k

3.3 Voltage supply

Power supply

The power supply depends on the selected output signal

4 ... 20 mA:

DC 10 ...36 V

DC 1 ... 5 V:

DC 8 ... 36 V

DC 0.1 ... 10 V: DC 14 ...36 V

Total current consumption

Current output (2-wire): Signal current, max. 25 mA

Voltage output (3-wire):

8 mA

3.4 Operating conditions

Ingress protection (per IEC 60529)

For ingress protection see chapter 3.5 "Electrical connec

-

tions"

The stated ingress protection only applies when plugged

in using mating connectors that have the appropriate

ingress protection.

Temperatures

Medium:

-40 ... +100 °C

2)

Ambient:

-40 ... +100 °C

1) 2)

Storage:

-40 ... +100 °C

1) Instruments with cable outlet are only suitable for an ambient temperature of -40 ... +80 °C.

2) G ¼ B flush with NBR sealing: minimum permissible medium and ambient temperature -30 °C

Overload safety of the process connections

G ¼ B EN 837:

see chapter 3.1

G ¼ B flush:

see chapter 3.1

¼ NPT ANSI/ASME 1.20.1:

see chapter 3.1

G ¼ A DIN 3852-E:

600 bar

3.5 Electrical connections

Available connections

Electrical

connection

Ingress protection

Wire

cross-

section

Cable

diameter

Circular connector

M12 x 1 (4-pin)

Measuring range < 100 bar:

IP 65

1)

Measuring range > 100 bar:

IP 67

-

-

Angular connector

DIN EN 175301-803 C

IP 65

2)

-

1.5 ... 6.0 mm

Cable outlet, from

PUR, 2 m

3)

Measuring range < 100 bar:

IP 65

1)

Measuring range > 100 bar:

IP 67

3 x 0.14 mm

2 4)

4.5 ... 5.0 mm

1) IP 67 on request

2) For conductor cross-section to max. 0.75 mm

2

3) Permissible ambient temperature -40 ... + 80 °C

4) For wire cross-section to max. 0.3 mm

2

, approx. AWG 22 with end splices

The stated ingress protection only applies when plugged

in using mating connectors that have the appropriate

ingress protection.

3.6 CE conformity

■

EMC directive, EN 61326 emission (group 1, class B)

and immunity (industrial application)

■

Pressure equipment directive

■

RoHS directive

For further specifications see WIKA data sheet PE 81.25

and the order documentation.

4. Design and function

4.1 Description

By means of a sensor element and by supplying power,

the prevailing pressure is converted into an amplified

standardised electrical signal via the deformation of a

diaphragm. This electrical signal varies in proportion to the

pressure and can be evaluated accordingly.

4.2 Scope of delivery

Cross-check scope of delivery with delivery note.

5. Transport, packaging and storage

5.1 Transport

Check the pressure transmitter for any damage that may

have been caused during transportation.

Obvious damage must be reported immediately.

1

2

3

4

5

6

7