376

326

~

+

•

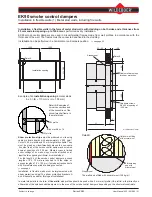

The limit switch for the "CLOSED position" (S1 contact with S2) of the smoke control damper is actuated at angle position < 3°.

•

The limit switch for the "OPEN position" (S4 contact with S6) of the smoke control damper is actuated at angle position ≥ 87°.

•

The intermediate position is signalled in angle position > 3° and < 87° (S1 contact with S3 and S4 contact with S5).

User Manual 5.32 (2018-05) 30

Subject to change

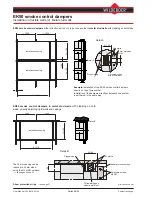

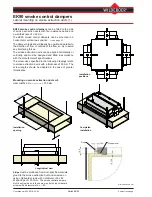

Series EK92

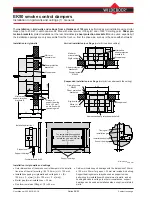

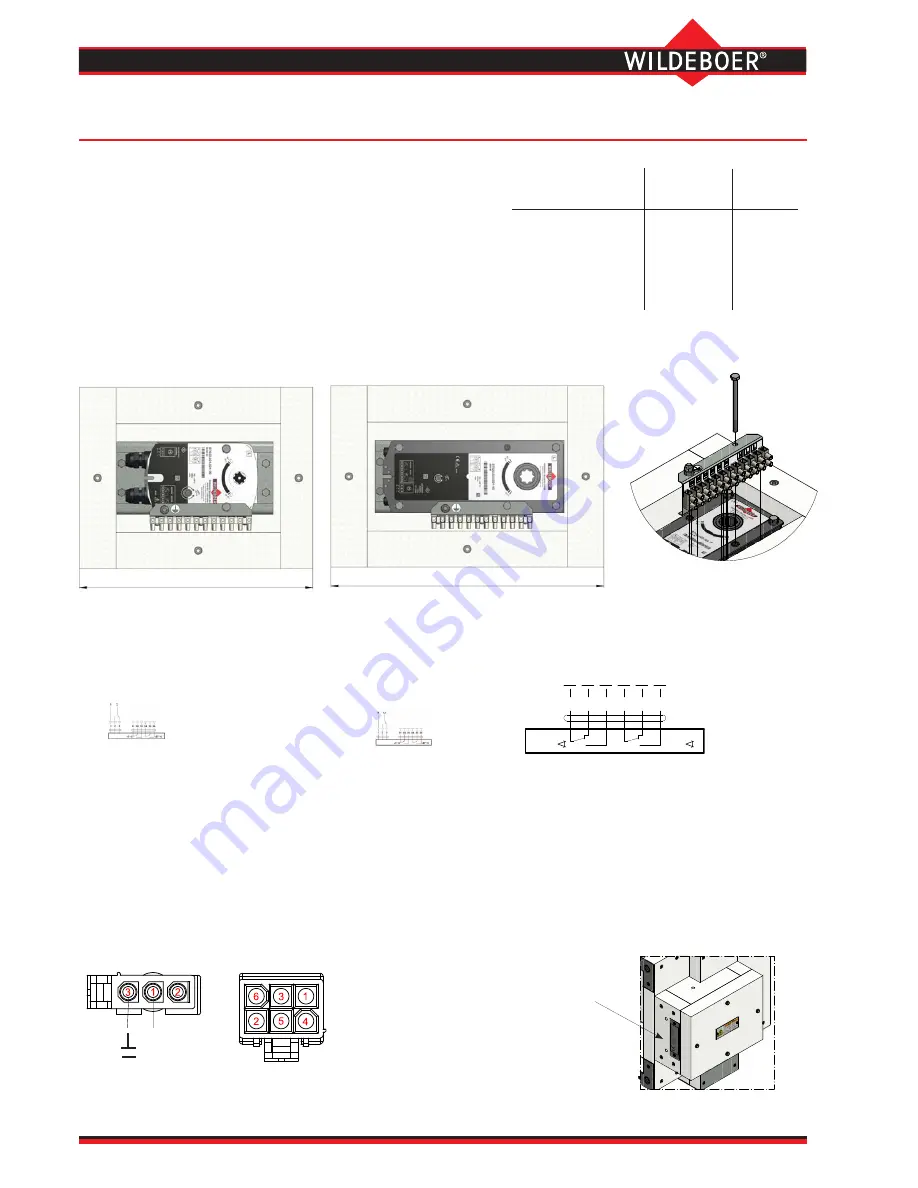

The

electric drive

is located to the side of the smoke control

damper, inside the calcium silicate

casing

.

The motor drive can be accessed by unscrewing the casing cover.

Electrical cables should be guided through the walls of the casing

for the motor drive on site.

Holes should be arranged for these as shown and matched to the

diameter of the cables.

Depending on the height H of the smoke control damper, motor

drives with difference performance data can be fitted:

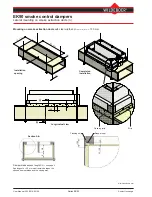

EK90 smoke control dampers

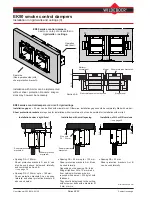

Electrical connection (1) motor drives

Electrical connection

Motor drives M1

24 V AC/DC

Electrical connection

Motor drives M2

230 V AC

Motor drive for standard design with

heights H = 200 to 450 mm

Motor drive for standard design with heights

H > 450 up to 800 mm and for special design of

electrical connection

Protection class IP54, runtime:

≤

60s

Motor drive

M1

M2

24 V AC/DC

230 V AC

Standard design

Height H

≤

450 mm

7.5 W / 9 VA 5 W / 12 VA

Height H > 450

mm

12 W / 18 VA 8 W / 15 VA

Special design of

12 W / 18 VA 8 W / 15 VA

electrical connection

Option:

terminal strip

for

electrical connection.

Motor drives for EK90 smoke control dampers

,

shown with the optional terminal strip for easy electrical connection.

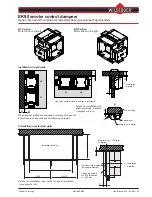

Additional casing for control units

⇒

see page 32

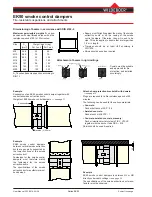

Configuration of AMP connectors on

motor drives 24 V AC/DC

S1 ... S6

S1 S2

S3 S4 S5 S6

<3°

<87°

Schematic circuit diagram:

Limit switch for "CLOSED position" actuated

in < 3° angle position, smoke control damper

is in "CLOSED position".

Limit switch assignment S1 to S6

Hole diameter = cable diameter

Casing for the motor drive

Recommended

hole positions

for

inserting the electrical

cables

are

labelled at the factory.

Required holes should be produced

as required on site.

1 = Ground neutral

2 = Rotation direction "OPEN"

3 = Rotation direction "CLOSED"