User Manual 5.32 (2018-05) 33

Subject to change

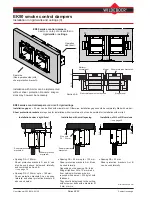

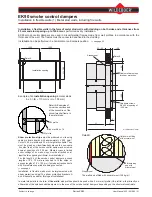

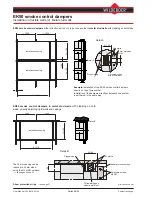

Series EK92

Installation

•

EK90 smoke control dampers, series EK92, must

be installed and operated in accordance with

this user manual and in compliance with all other

regulations.

In addition, smoke control dampers must be installed

tension-free and appropriately aligned.

Air flows in the smoke extraction ducts must not

adversely affect the torques acting on the damper

blade by the motor.

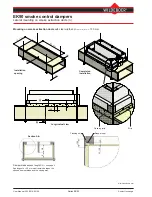

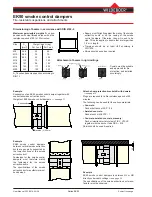

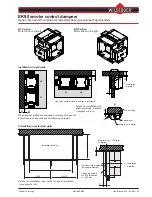

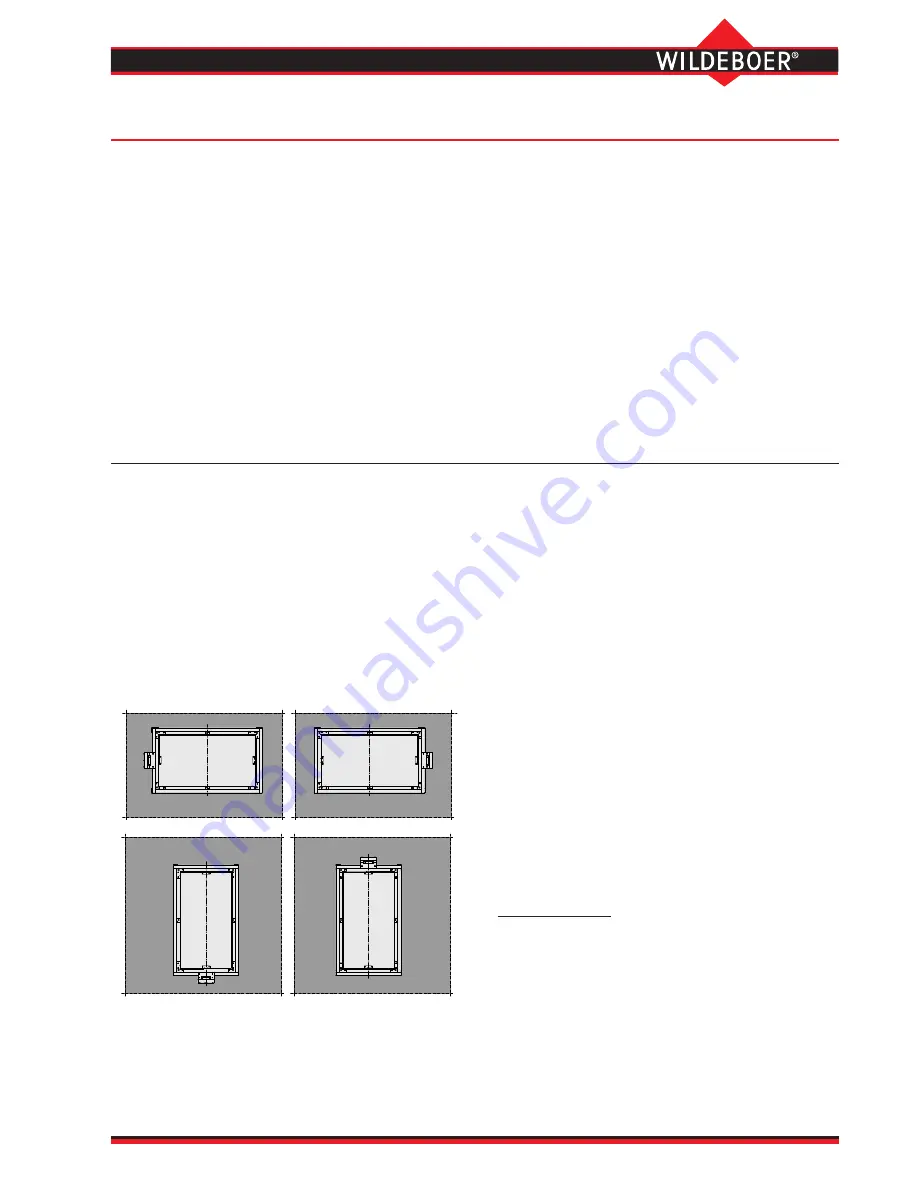

Installation can be performed in a horizontal or vertical

axis position.

Casings should be installed in installation openings

in walls such that they lie largely flush on the bot

-

tom side. If remaining gaps are filled with mineral

wool, a melting point of ≥ 1000°C must be verified

for this. Shear protection brackets should be installed

accordingly.

Structural requirements and concerns, as well as rele

-

vant manufacturer's specifications, should be verified

and observed by the customer.

•

Smoke control dampers for outside air supply must

be installed such that heavy moisture penetration is

avoided, in particular in the event of frost exposure.

•

Assembly, electrical wiring, connections etc. must be

produced on site.

•

Smoke extraction ducts and electrical equipment must

be suitable, and must be correctly installed and con-

nected.

•

Inspection openings must be provided on site in the

smoke extraction ducts if necessary.

Functional testing/servicing

•

In accordance with German regulations, smoke extrac

-

tion systems must be serviced and kept ready for oper-

ation by the owner. The smoke control dampers must

be tested for correct functioning at six-month intervals.

If successive tests are passed without any defects, the

next text may be carried out after one year.

•

Operating instructions

for the EK90 smoke control

dampers, Series EK92, are available on the Internet at

www.wildeboer.de.

In general, actuating (closing and opening) the smoke

control dampers is sufficient in testing the function.

This can be performed by means of remote actuation.

EK90 smoke control dampers do not generally require

any maintenance work.

The cleaning of smoke extraction systems should be

performed in an operation-dependent manner, and

also includes the smoke control dampers.

Repairs or service work are required in the event of

malfunctions.

Original spare parts must be used.

•

EK90 smoke control dampers, Series EK92, are suit

-

able for smoke extraction systems and for combined

systems for smoke extraction and building ventilation.

They supersede the former EK90 smoke control damp-

ers in accordance with approval Z-78.2-7 and EK90

smoke control dampers with ventilation function in

accordance with approval Z-78.3-104.

•

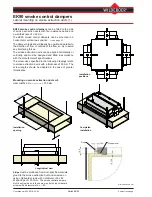

EK90 smoke control dampers, series EK92, in

sys-

tems only for smoke extraction

are usually closed.

In the event of fire, all of them or only those required

can be opened from the outset. As the fire develops

and smoke is released, other ones can be opened and

the previously opened ones can be closed again.

•

EK90 smoke control dampers, Series EK92, required

for building ventilation in

combined systems for

smoke extraction and building ventilation

are usual-

ly opened, whereas others are closed.

In the event of fire, the smoke control dampers required

for smoke extraction are opened or are kept open,

while others are closed or remain closed.

•

As the fire develops and smoke is released, other

EK90 smoke control dampers, series EK92, can be

opened and previously opened ones can also be

closed.The function with HOT classification is verified.

•

EK90 smoke control dampers, series EK92, can still be

opened 25 minutes after the onset of full fire exposure.

The function with MA classification is verified.

Function of smoke extraction systems with EK90 smoke control damper, Series EK92

EK90 smoke control dampers

Function in smoke extraction systems - installation - functional testing/servicing