Heating

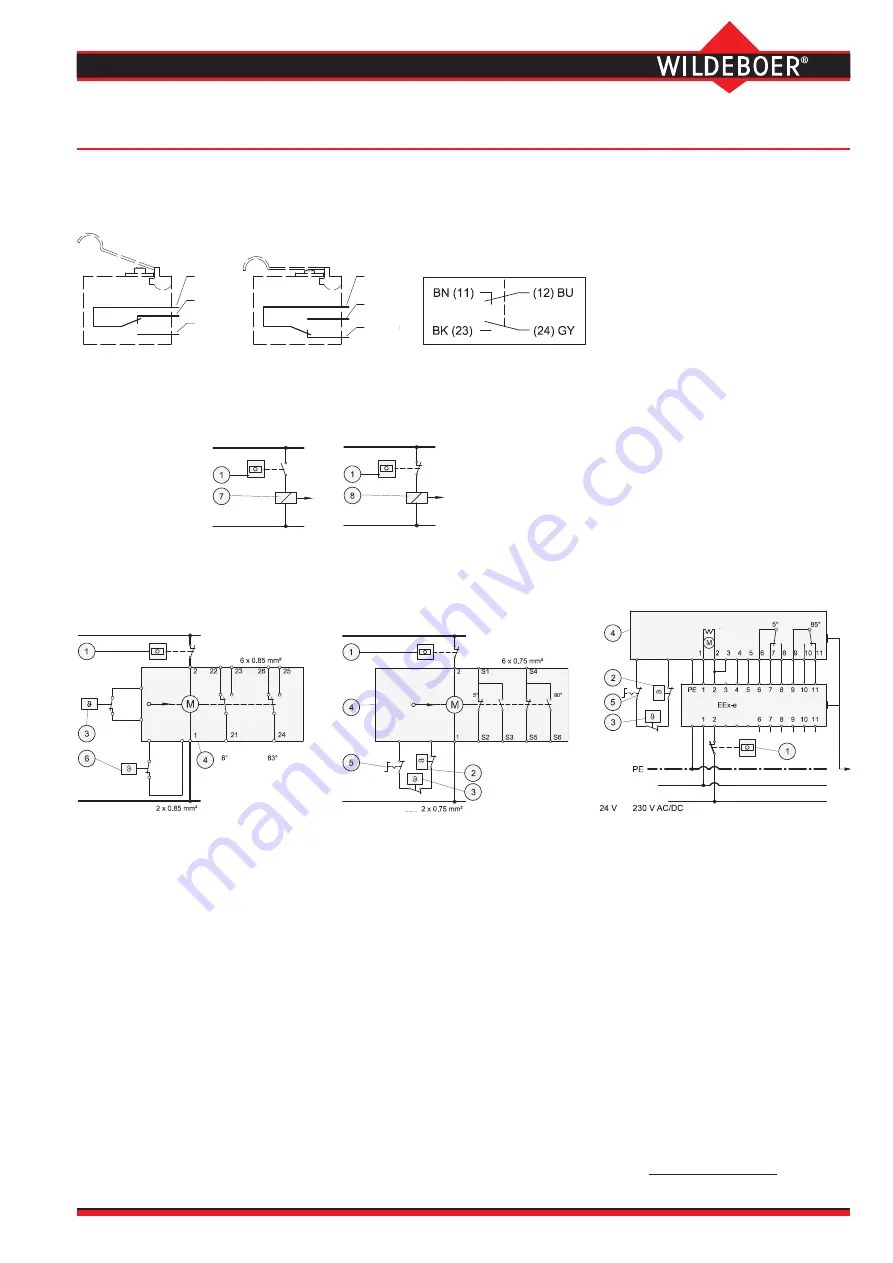

CLOSED

OPEN

terminal box

Control voltages

to

Potential equation

(on site)

Control voltages

230 V AC or 24 V AC/DC

Cable

Cable

Fire damper

CLOSED OPEN

Control voltages

230 V AC or 24 V AC/DC

Cable

Cable

CLOSED

OPEN

CLOSED OPEN

Fire damper

white

white

white

green

green

brown

brown

white

white

white

green

green

brown

brown

User Manual 5.02 (2016-10)

13

Subject to change

Series FK120

FK90 fire dampers

Electrical connections, installation, functional testing, servicing

Actuators EM-1, EM-2 and RM-1

Actuators M220-7, M24-7

Limit switches

on thermal-mechanical release mechanisms

The CLOSED limit switches are actuated when the fire damper is closed, and the OPEN

limit switches are actuated when the fire damper is open.

Limit switch not actuated

Limit switch actuated

Actuators M220-9/V, M24-9/V

Remote release

E-Ex limit switch

Installation

•

FK90 fire dampers, series FK120, must be installed based

on the instructions in this user manual. The technical

regulations and national statutory regulations must be obser

-

ved during installation.

In Germany, this means the “Technical Building Regulations”

(VV TB) and the "Guideline on Fire Protection Requirements

Pertaining to Ventilation Systems" (Lüftungsanlagenrichtlinie -

LüAR).

FK90 fire dampers meet these requirements and generally

recognised technical regulations.

•

Electric wiring

must be installed by the customer.

•

Potential equalisation conductors

to bridge flexible

connection pieces on fire dampers can be fastened

with metal screws if they are made of copper up to a

cross-section of 6 mm² or made of aluminium.

•

Fire dampers in

potentially explosive atmospheres

must

be grounded in accordance with regulations.

Functional testing and servicing

•

Fire dampers must be serviced by the owner and tested

periodically to ensure they are functioning correctly.

The intervals largely depend on the system operation. Rele

-

vant regulations should be followed.

•

FK90 fire dampers, series FK120, are maintenance-free due

to fully enclosed components, corrosion-resistant materials

and precise manufacture.There is no need for regular clea

-

ning and lubrication, which would otherwise be necessary.

•

Functional tests on FK90 fire dampers, series FK120, are

generally limited to a release and re-opening.This can be

performed remotely with electric actuators.

•

Repairs or service work are required in the event of malfunc

-

tions.Original spare parts must be used for this.

•

Cleaning work required in ventilation systems for hygiene

reasons must be performed in an operation-dependent

manner, and also includes the fire dampers.

Operating instructions

for the FK90 fire dampers, series FK120, can be downloaded online at www.wildeboer.de/en

.

W220, G24

Closed during current flow

WU220, GU24

Closed during power interruption

Control voltages 230 V AC or 24 V DC

Limit switch not actuated

Connection cable colour coding

1 Thermostats, smoke detectors and switches

should only be installed if required.

On site delivery.

2 Thermal-electrical release element

70°C or 95°C; EM-1,

EM-2 and RM-1 only 70°C!

3 Thermal cut-off approx. 70°C

4 Electric actuator with limit switches for

OPEN-CLOSED position indicator.

The illustration shows the de-energised

operating position where the fire dam

-

pers are closed.

•

The plugs on the connection cables can

be removed if they are not being used.

•

Due to their in-built thermal release ele

-

ments, all actuators must be stored at tem

-

peratures not exceeding 50°C.

5 Switches or buttons for testing the actuators

6 Thermal-electrical release element 70°C or

100°C with plug-in connection for testing the

actuator.

7 Lifting solenoid

8 Magnetic clamp

The right to allow for variations in delivery from

the versions shown remains reserved

.