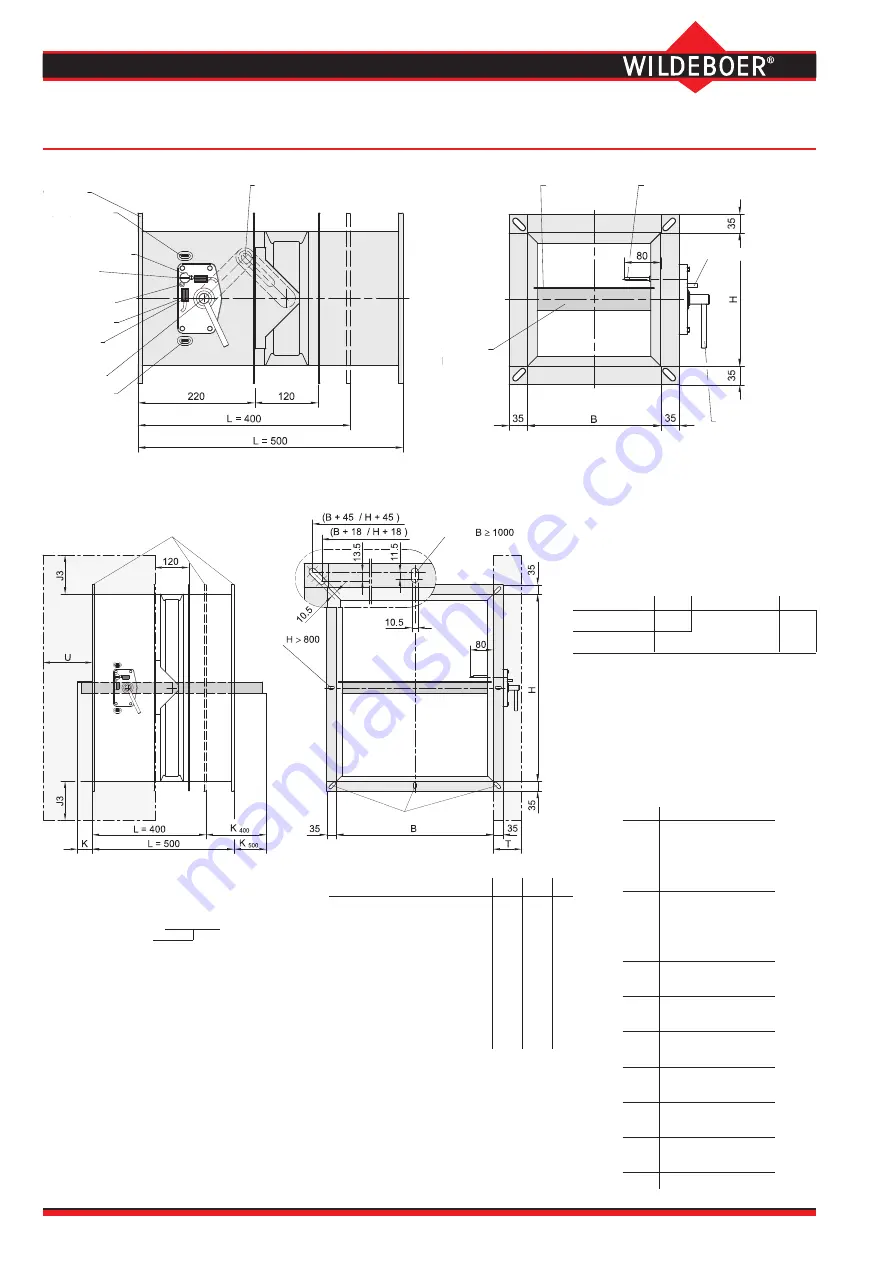

Release element

Lip seal

Damper

blade

Manual lever

Manual release

Casing

Control opening

Thermal-

mechanical

release mechanism

Limit switch

E-CLOSED (optional)

Manual release

Operation unit

Limit switch

E-OPEN (optional)

Closing spring

Control opening

Enclosed transmission

Operation side down

Operation side up

Connection flanges

only, if

only, if

Connection holes

User Manual 5.0-2 (2016-10) 6

Subject to change

Series FK120

Damper blade

•

Operation side: K

•

Non-operation side: K

400

, K

500

L = 400 and L = 500

Height-independent excess lengths

T U J

Thermal-mechanical release

mechanism

95

-

-

with:

•

W220, WU220

120

•

G24, GU24

120 -

-

•

P, P2

105 -

-

•

E-Ex limit switch

105 -

-

M220-9/V, M24-9/V

90

- -

M220-7, M24-7

145 40

-

EM-1, EM-2, RM-1

245 150 J3

Thermal-mechanical release mechanisms

are labelled with

V1, V2, V4

and are mounted

based on the width B and height H of the fire

dampers.

These size-dependent allocations must not

be changed on site!

H

J3 K K

400

K

500

200 170 -

-

-

225 160 -

-

-

250 145 -

-

-

275 135 -

4

-

300 120 -

17

-

325 110 -

29

-

350 95

-

42

-

375 85

-

54

-

400 70

-

67

-

450 45

-

92

-

500 20 - 117 17

550

-

- 142 42

600 -

7 167 67

650

-

32 192 92

700 - 57 217 117

750

-

82 242 142

800

- 107 267 167

850

- 132 292 192

900

- 157 317 217

950

- 182 342 242

1000 - 207 367 267

Additional space must be provided for assembly, electrical connections

and servicing; observe the cable entry points!

In addition to the

"T" measurement

, it is recommended that a distance of 400

mm be kept from adjacent walls, ceilings or other fire dampers, in order to ensu

-

re that the release mechanisms and actuators can be accessed for operational

purposes.

Connection flanges

are fitted with connection holes. If additional holes are requi

-

red for duct connection, these can be added on site!

H/B

≤

400 > 400 to 750 > 750

≤

300

V2

V4

V1

> 300 to 1000

FK90 fire dampers

Data sheet (1) Dimensions

Maximum excess lengths

of mechanical and electrical equipment parts.

Actuators

U horizontal (delivery condition)

J rotated to vertical or suspended position:

J3 EM-1, RM-1, EM-2