WIL-11160-E-09

Wilden

®

11

Suggested Installation, Operation, Maintenance and Troubleshooting

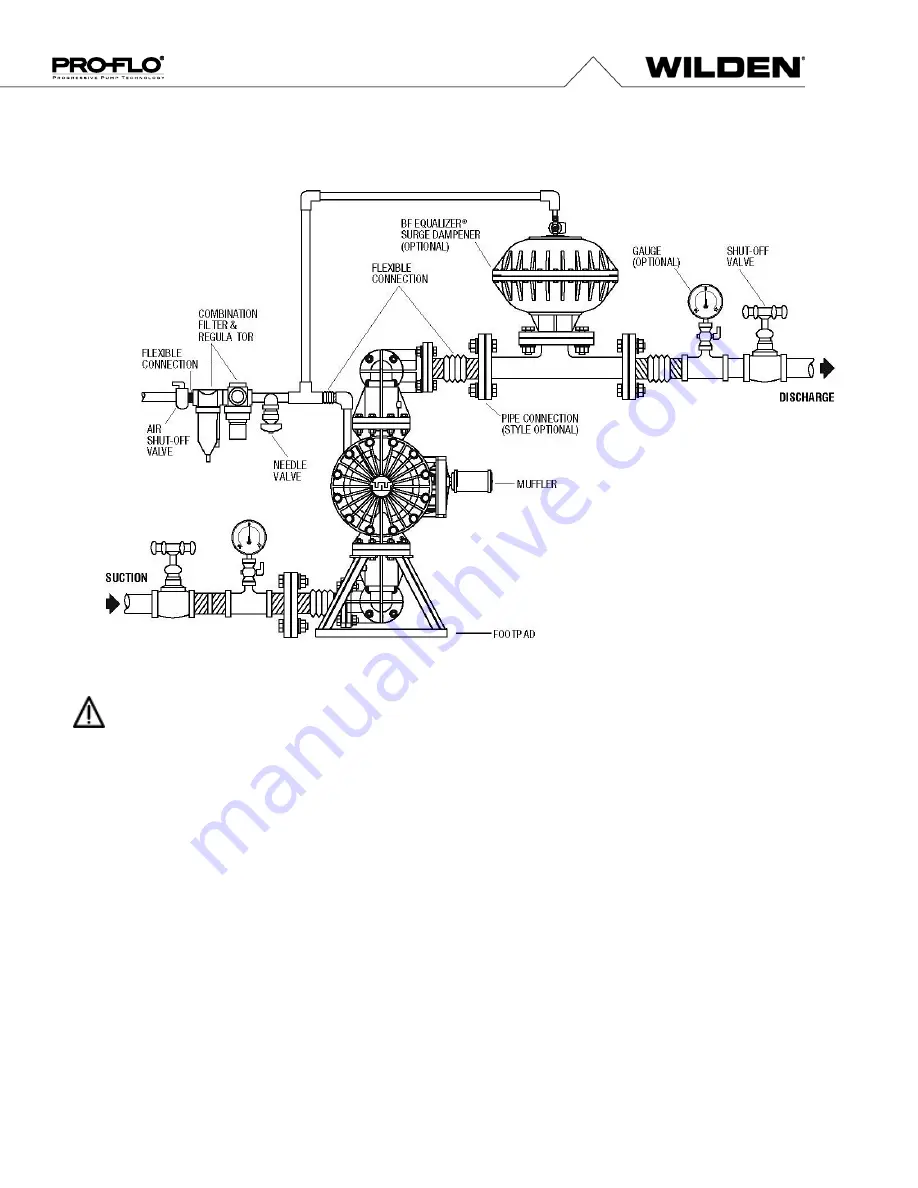

This illustration is a generic

representation of an air-operated

double-diaphragm pump.

NOTE:

In the event of a power failure, the shut-off

valve should be closed, if the restarting of the pump is

not desirable once power is regained.

Air-Operated Pumps:

To stop the pump from operating in an

emergency situation, simply close the shut-off valve (user-

supplied) installed in the air supply line. A properly functioning

valve will stop the air supply to the pump, therefore stopping

output. This shut-off valve should be located far enough away

from the pumping equipment such that it can be reached safely

in an emergency situation.

Operation

The P1500 is pre-lubricated, and does not require in-line

lubrication. Additional lubrication will not damage the pump,

however if the pump is heavily lubricated by an external source,

the internal lubrication may be flushed out. If the pump is then

moved to a nonlubricated location, it may need to be

disassembled and re-lubricated as described in the

DISASSEMBLY / REASSEMBLY INSTRUCTIONS.

Pump discharge rate can be controlled by limiting the volume and/or

pressure of the air supply to the pump. An air regulator is used

to regulate air pressure. A needle valve is used to regulate volume.

Pump discharge rate can also be controlled by throttling the pump

discharge by partially closing a valve in the discharge line of the pump. This

action increases friction loss which reduces flow rate. (See Section 5.) This is

useful when the need exists to control the pump from a remote location. When

the pump discharge pressure equals or exceeds the air supply pressure, the

pump will stop; no bypass or pressure relief valve is needed, and pump

damage wil

l not occur. The pump has reached a “deadhead” situation and can

be restarted by reducing the fluid discharge pressure or increasing the air inlet

pressure. Wilden Pro-Flo

®

pumps run solely on compressed air and do not

generate heat; therefore, your process fluid temperature will not be affected.

Maintenance and Inspections

Since each application is unique, maintenance schedules may be different for

every pump. Frequency of use, line pressure, viscosity and abrasiveness of

process fluid all affect the parts life of a Wilden pump. Periodic inspections

have been found to offer the best means for preventing unscheduled pump

downtime. Personnel familiar with the pump’s construction and service should

be informed of any abnormalities that are detected during operation.

Summary of Contents for PRO-FLO P1500

Page 23: ...WIL 11160 E 09 Wilden 23 Notes...