WILDEN PUMP & ENGINEERING, LLC

24

WIL-12310-E-04

T o o l s R e q u i r e d :

• Adjustable

Wrench

•

Vise equipped with

soft jaws (such as

plywood, plastic

or other suitable

material)

CAUTION:

Before any maintenance or repair is attempted, the compressed air line

to the pump should be disconnected and all air pressure allowed to bleed from the

pump. Disconnect all intake, discharge, and air lines. Drain the pump by turning it

upside down and allowing any fl uid to fl ow into a suitable container. Be aware of

any hazardous effects of contact with your process fl uid.

NOTE:

The model photographed for these instructions incorporates PTFE

diaphragms.

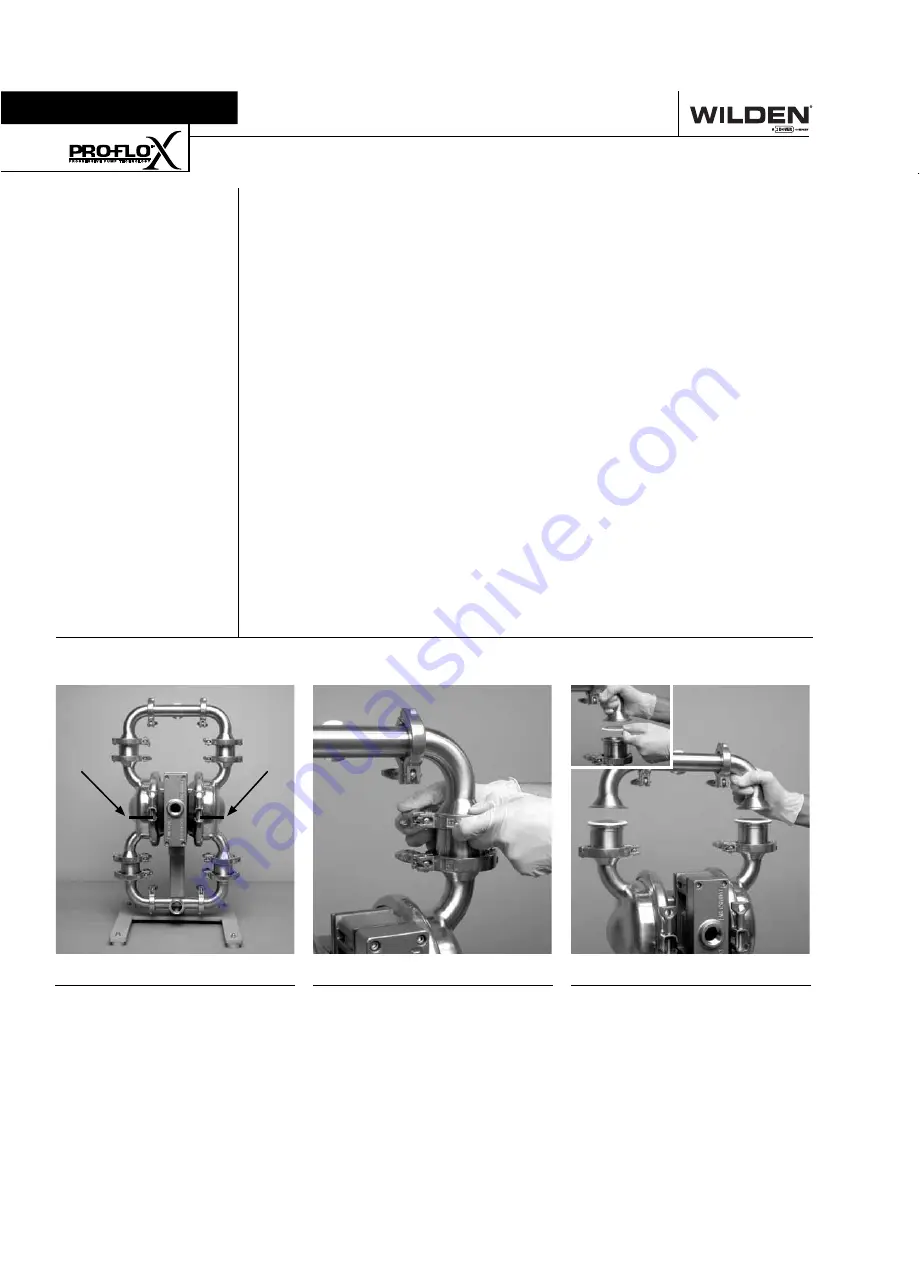

Step 1

Prior to assembly, alignment marks

should be placed on the liquid

chambers and air chambers to

assist with proper alignment during

reassembly.

Step 2

Loosen the wing nut and remove

both discharge manifold clamp

bands.

Step 3

Remove the discharge manifold and

manifold gaskets.

S e c t i o n 7

P U M P D I S A S S E M B L Y

S e c t i o n 7

A s s e m b l y / D i s a s s e m b l y

Summary of Contents for PX4 series

Page 9: ...PX8 P X 8 S A N I F L O H S P E R F O R M A N C E S A N I F L O...

Page 22: ...N O T E S...

Page 41: ......

Page 42: ...N O T E S WILDEN PUMP ENGINEERING LLC 40 WIL 12310 E 04...