Page 2 WILKERSON

OPERATIONS

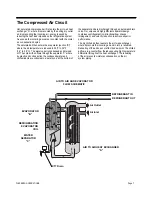

WHY YOU NEED A WILKERSON

REFRIGERATED AIR DRYER

Untreated compressed air will contain contaminants

such as water, compressor oil, rust, chemical conta-

minants, and bacterial growth.

All of these contaminants will cause corrosion and

product contamination.

With proper filtration and a Wilkerson refrigerated air

dryer in use, contaminants will be reduced to a harm-

less level.

The end result will be that the equipment which comes

in contact with dry, treated, compressed air will stay

cleaner, will not corrode, and will last longer.

Rejection rates of your end products will drastically

reduce when using dry, treated air in your plant

manufacturing operation.

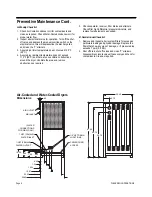

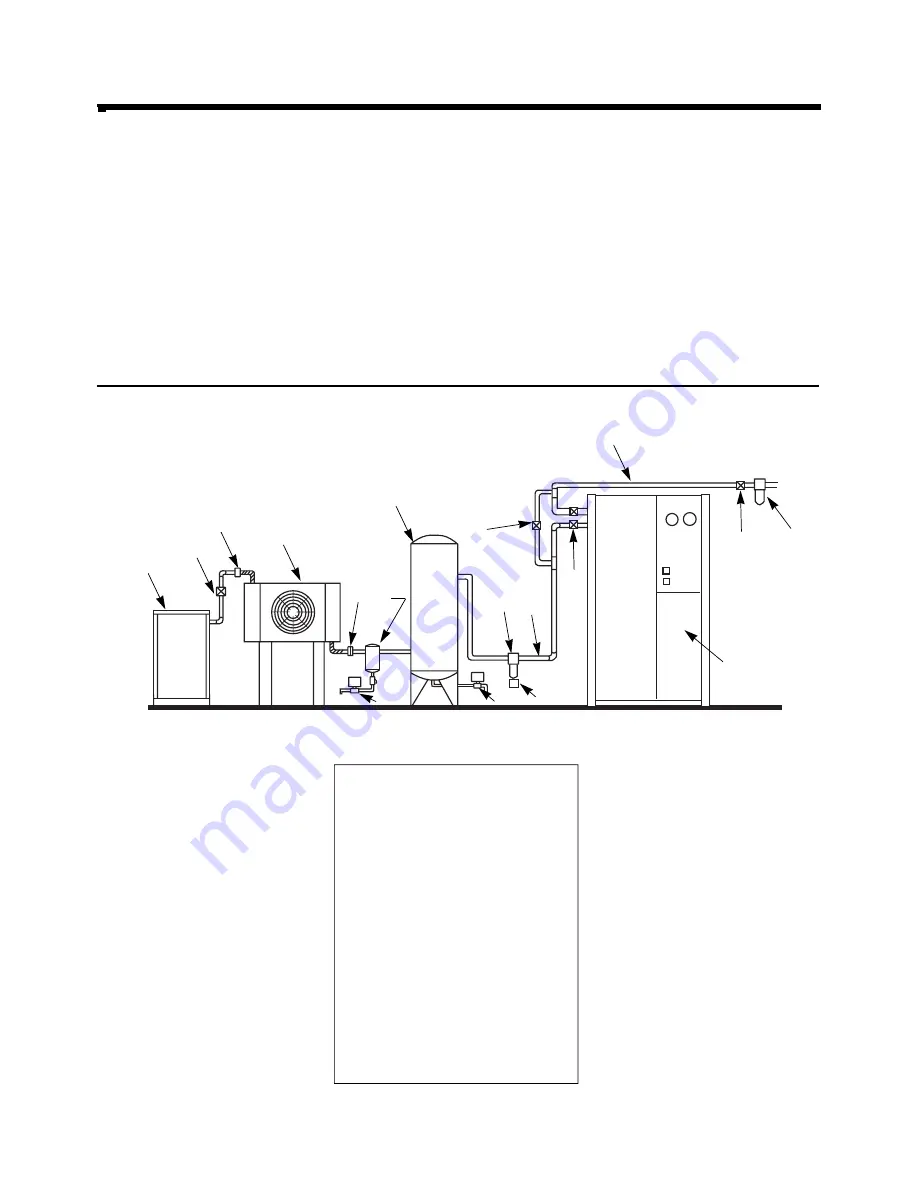

FIGURE 1: TYPICAL COMPRESSOR ROOM LAYOUT:

1 Air Compressor

2 Shut-off Valve

3 Flex Connector

4 Compressed Air Aftercooler

5 Flex Connector

6 Liquid Separator with

Electric Drain

7 Storage Tank

8 Prefilter

9 Electric Drain Valve

10 Flex Connector

11 Shut-off Valve

12 By-pass Valve

13 Flex Connector

14 Shut-off Valve

15 Afterfilter

16 Refrigerated Air Dryer

1

2

3

4

7

13

11

14

15

16

12

5

6

9

9

9

8

10