WILKERSON

OPERATIONS

Page 3

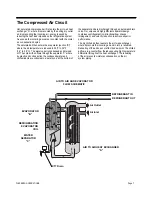

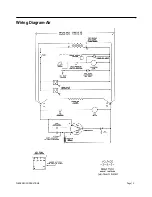

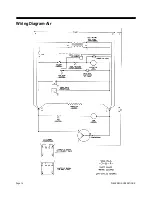

The Air Compressor 1

Although there are many types of compressors, all have

some type of inlet filtration. If this filtration is not maintained

or is not properly designed for ambient conditions (ie. large

amounts of coal dust, road dust, fly ash, etc.) the result will

be increased compressor maintenance and an additional

contamination load on downstream equipment.

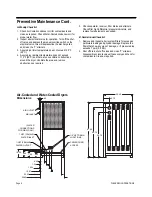

Shut-Off Valve 2, 11, 14

Sized in accordance with air flow capacities, to provide the

minimum pressure drop.

Flexible Connections 3, 5, 10, 13

Flexible piping between a compressed air system and the air

dryer or aftercooler is recommended to eliminate any

possible vibration induced damage.

The Aftercooler 4

As the name implies, the aftercooler cools the hot air after

compression. This not only reduces the temperature of the

air to within acceptable values for downstream equipment,

but also condenses out a very large amount of water. This is

very important because for approximately every 20°F (11°C)

reduction in compressed air temperature, one half of the

water is condensed. A separator must be used to actually

remove the water from the system.

The Separator 6

The separator removes the large droplets of oil and water

from the compressed air stream which condense in the

aftercooler, subsequently improving the dryer capacity.

Though one of the least expensive components of the

compressed air system, the separator is one of the most

critical. A difference of only a few percent efficiency in a

separator can allow substantial amounts of additional water

to pass downstream, both overloading a dryer and causing

potential maintenance problems. A properly sized electronic

drain should be installed to drain away accumulated liquids.

Storage Tank 7

This acts as a storage vessel which will also remove liquids.

Therefore, an electric drain valve should be installed. (Note:

Where possible the receiver should be installed with the

inlet near the bottom and the outlet near the top.)

Prefiltration 8

Wilkerson refrigerated air dryers will operate efficiently and

reliably without filtration. But if your system also requires dirt

and oil free air, then appropriate particulate or coalescing

filtration is required.

Electric Drains 9

Proper drainage of accumulated liquids is essential to proper

system operation. Should liquids be allowed to build up in

receivers and filters, liquid “slugging” can occur causing loss

of performance to downstream components.

Automatic electric drain valves provided on the dryers

automatically drain liquid water from the dryer evaporator and

separator. They feature full adjustment of drain cycles from 1

to 45 minutes, and valve opening durations from 1 to 15

seconds. Two indicator lights for indicating “power on” and

“valve open” status allow for easy visual inspection. Electric

drains are also recommended for all other drain points in the

compressed air system including separators, filters,

receivers, and drip legs.

By-pass Valve System 12

It is strongly recommended that a by-pass valve system be

utilized to provide for convenient maintenance and service.

Applications which require a continuous supply of dry air

should consider installing two dryer systems. This will assure

a steady supply of dry air under any conditions.

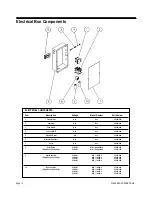

Afterfiltration 15

For critical applications, to obtain a maximum downstream oil

content of .01 ppm/wt and .003 ppm/wt respectively. See the

chart below for recommended afterfilters.

The Refrigerated Air Dryer 16

The Wilkerson Refrigerated Air Dryer is the result of

unprecedented research and testing. It is subjected to

simulated no load, partial load and full load performance

examinations to meet our quality standards. As such, it will

provide years of reliable service if properly installed and

operated within its design specifications. The dryer should be

installed in a well ventilated area.

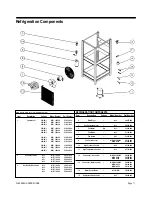

Components Of A Refrigerated Dryer Compressed Air System

Recommended Filtration

Recommended Coalescing Prefilters/Afterfilters

Dryer

Dryer/Filter

Model

Pipe

Type A

Type B1

Type C

Number

Size

5.0 Micron

1.0 Micron

(.01 ppm downstream

Inlet/Outlet

Particulate

Coalescing

remaining oil content)

WR( )-0250

2" NPT

F35-0

C

-

0

00

M35-0C-S00

M35-0

C

-000

WR( )-0300

2" NPT

F35-0

C

-

0

00

M35-0C-S00

M35-0

C

-000

WR( )-0400

2" NPT

F35-0

C

-000

M36-0C-S00

M36-0

C

-000

WR( )-0500

2" NPT

F35-0

C

-000

M36-0C-S00

M36-0

C

-000

NOTE: Recommended filters were selected on the basis of flow capacity—not pipe size.