Page 6 WILKERSON

OPERATIONS

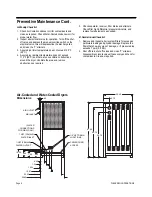

Preventive Maintenance Cont.

A. Weekly Checklist

1. Check Air-Cooled condenser coil for contaminants and

clean as required. Check Water-Cooled condenser coil for

proper water flow.

2. Inspect all electrical drains for operation. Turn off the shut-

off valve and depress the manual override switch on the

electrical valve, this will depressurize the discharge line,

and clean the “Y” strainers.

3. Assure dryer inlet temperature does not exceed 120°F

(48°C).

4. Assure dryer ambient temperature does not exceed

110°F (43°C) and there are no ventilation obstructions

around the dryer. Ventilate the area and remove

obstructions as required.

5. Check separator, receiver, filter drains and strainers.

Check filter high differential pressure indicators, and

replace fouled elements as needed.

B. Semi-Annual Checklist

1. Remove and inspect all air system filters for excessive

particulate loading and physical damage. Replace the

filters that show any sign of damage, or if pressure drop

exceeds 7 psid (0,5 bar).

2. Shut off drain shut-off valves and clean “Y” strainers.

Disassemble solenoid valves if necessary and check for

contaminants. Clean as required.

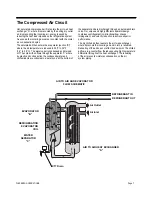

10.38

9.36

7.88

6.50

.50

67.88

60.75

54.75

35.42

6.75

5.06

1/4" NPT DRAIN

LOCATIONS

POWER CORD

ACCESS

AIR INLET

AIR OUTLET

7.56

10.25

12.87

25.25

29.62

1

/

2

NPT (FEMALE)

WATER OUTLET

1

/

2

NPT (FEMALE)

WATER INLET

(WATER

CONNECTIONS

FOR WRW ONLY)

Air-Cooled and Water-Cooled Dryers

Dimensions