Installing Your Furnace

12

Surface Mount Installation

The use of the optional Free Standing Accessory No. 4901 allows

single-sided furnaces to be surface mounted instead of recessed

into a wall. This is ideal for remodeling existing masonry wall

construction or when studding is substandard. This kit drastically

cuts installation time and eliminates the expense of cutting into

the walls and ceiling plates. Be sure this accessory is of the type

and design required for the use with your furnace.

NOTE:

After picking a location that meets the requirements,

check the wall, attic, and roof to make sure there are no

obstructions such as pipes, electrical wiring, etc., which could

interfere with the installation of the furnace or vent pipe. If

required, move them or pick a new location.

FIND THE WALL STUDS OR CEILING JOISTS

Find two studs or joists at the spot where the furnace is to be

located. Use a stud locator or small finishing nails. Repeatedly

drive and remove a nail into the wall or ceiling in the area of the

stud or joust until you find it. Then find the its side and leave the

nail there. Drive another nail just on the other side other the same

stud or joist.

The inside of the next stud or joist should be about 14½ inches

from the first one found. Drive a nail on the inside of this stud or

joist.

Using the nails as a guide, draw two lines down the side of the

wall from the ceiling to locate the furnace and ceiling hole cutout

for venting.

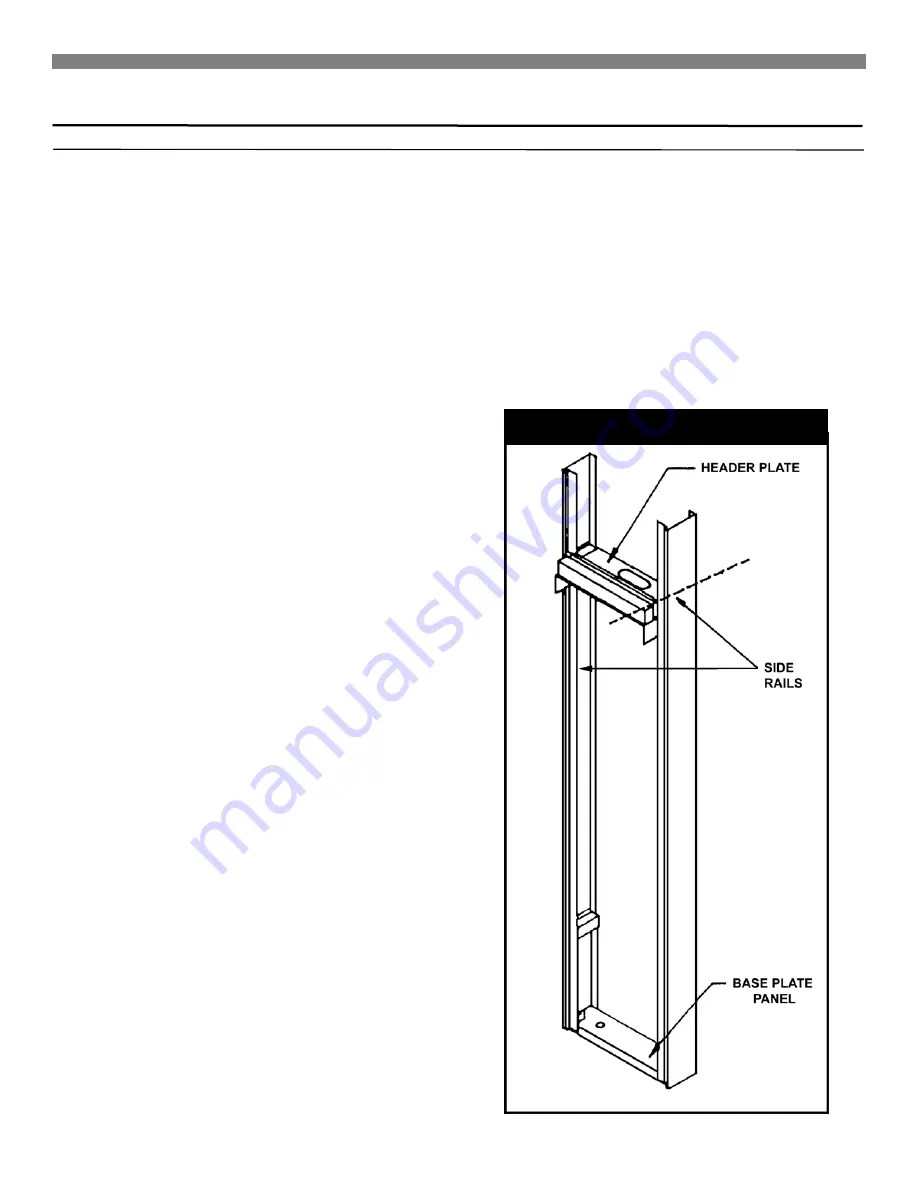

FREE STANDING ACCESSORY ASSEMBLY & INSTALLATION

1.

Attach the base plate panel as shown in Figure A to the

bottom of the side rails with four (4) # 6, ⅜”

screws.

2.

Attach the header plate, (included with the furnace), to the

side rails using four (4) #8, ⅜” screws. Flanges of the header

plate go against the wall. (Figure A).

3.

Install extension side rails as shown in Figure A, by

telescoping them inside the lower side rails. Adjust the

extension side rails by sliding them up or down to ceiling

height. Maximum: 8 feet 9 inches, Minimum: 7 feet 9 inches.

4.

If the wall has a baseboard, cut the baseboard out to fit

against the side rails. Stand the side rails against the wall and

fasten them to the wall securely with screws or bolts in the

holes provided. Use a level to assure the enclosure is plumb.

Screws and bolts for wall fastening are not included

.

5.

After positioning the enclosure, cut a 3½ X 14 inch hole in the

ceiling, centered between the studs or joists as shown in

Figure B.

6.

Cut ¼ inch off each end of the ceiling spacer plate. Place the

ceiling spacer plate to the back of the wall and centered in the

enclosure as shown in Figure C.

7.

Install Type B/W vent though the roof and studs or joists in

accordance with the installation instructions packed with the

furnace and local codes.

See Vent Installation, page 14.

8.

Set the furnace body into position. (Figure 9), page 15. The

furnace legs will rest on the bottom of the base plate panel.

Utilizing the holes provided in the furnace legs, secure the

furnace to the brackets attached to the bottom panel with two

(2) #10, ¾” screws.

9.

Install the vent enclosure panel, fastening it to the side rails

with six (6) #6, ⅜” screws. Trim the bottom of the panel to fit

the header plate.

10.

Install gas inlet through the back wall or one of the two holes

provided in the bottom base plate panel. (Figure D.) Connect

gas line to furnace

. See Gas supply and Piping, page 17.

11.

Install furnace face panel.

See Front Panel Installation,

page 18.

NOTE: The panel recesses ¼-inch between the

vertical edges of the enclosure.

FIGURE A