Introduction

6

KEEP THESE INSTRUCTIONS FOR FUTURE REFERENCE

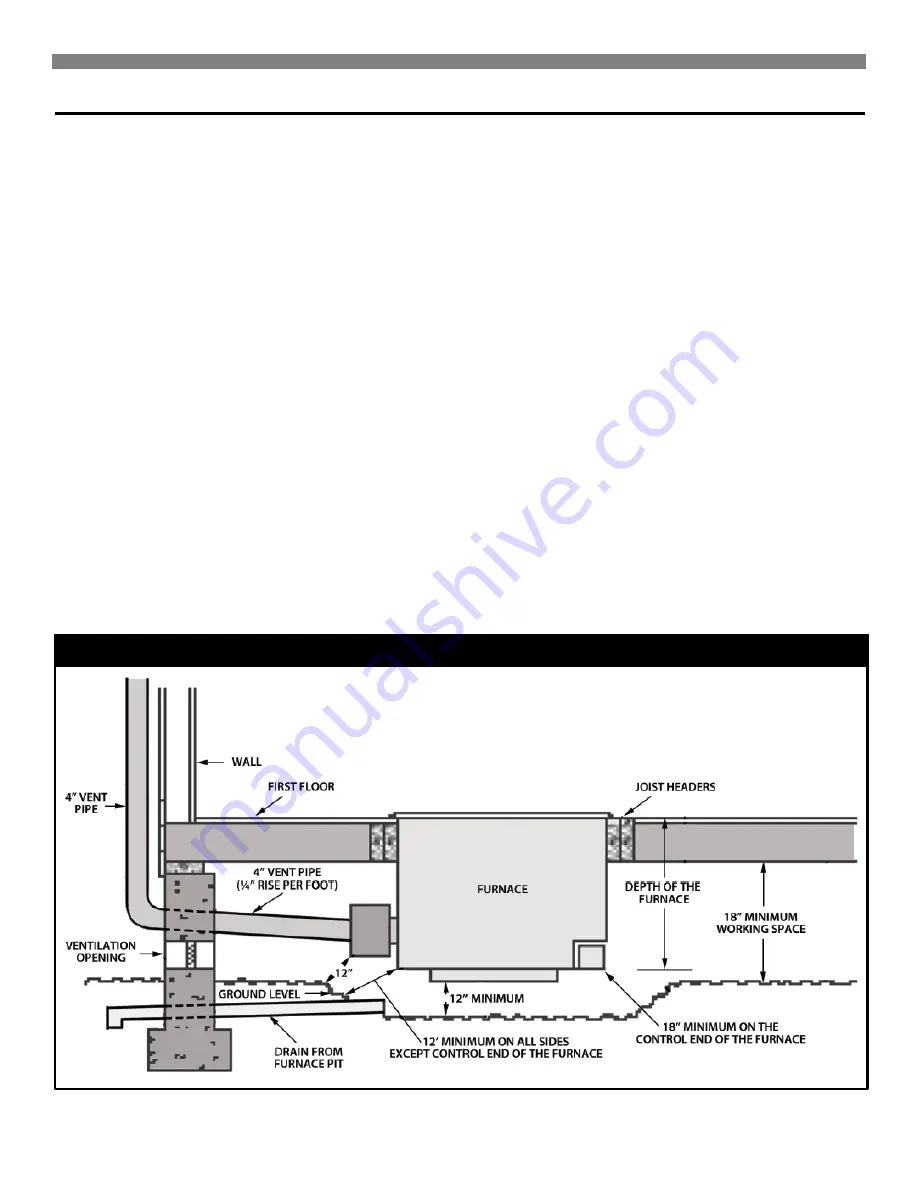

All furnaces require a supply of oxygen for combustion. To assure

this furnace receives the necessary oxygen, two free air openings

of at least one square inch for each 1,000 Btu/hr. input rating of

the furnace must be provided in the foundation of the house (see

figure 1). Be sure these openings are located where the air can

flow to the furnace and is not likely to be blocked.

This furnace is equipped with a temperature limit control that limits

the register temperature under normal conditions of operations.

This control may be overridden under unusual circumstances,

such as extremely cold weather, to allow more heater output from

this heater. A complete explanation of the operation of this control

is contained in the "Operating Your Furnace" section of these

instructions.

An inspection of the furnace and attached systems should be

performed at least once each year by a qualified service

technician. More frequent inspections are advisable if the furnace

is installed or operated in a manner that might cause the

accumulation of dust or dirt in the furnace or the failure of

component parts more rapidly than would normally be expected.

Keep all combustible materials, gasoline and other flammable

liquids or vapors away from this furnace, and be sure that

combustion and ventilation air openings supplying this furnace are

kept clear at all times.

Continued safe and satisfactory performance of this furnace

requires, but is not limited to, periodic examination of the vent

system, pilot flame, combustion chamber, liners and gas supply

lines and periodic cleaning of the burner air intake, pilot and

control areas. The venting system, including the factory provided

draft hood and all other parts of the vent, must be inspected

periodically for indications of failure, such as loose joints, rusting

components or broken parts. Any defective or damaged part,

which does not provide a continuous conduit to carry the

combustion products to the outside, must be replaced before the

furnace is operated. A complete description of the venting

requirements is contained in the "Venting and Chimney

Requirements" section of these instructions.

This furnace is designed to burn only the type of gas that is

indicated on the rating plate, visible on the bracket directly

beneath the floor grille. Do not attempt to use this furnace with

any other type gas. If you are not sure what type gas is available

in your locality, obtain this information from your local gas supply

company.

The pilot and control system of this furnace will automatically stop

the gas flow to the pilot burner and main burner if the pilot flame is

extinguished. This system also generates the electricity required

to operate the thermostat system. Since no electrical power is

required from any other source, this furnace will continue to

operate during a power outage.

FIGURE 1

Air Openings