PMP-112 Multiposition

Oil Furnaces

–

Furnace Manual

6

11/13

1.6.1

Masonry chimney

This furnace can be vented into an existing masonry chimney.

However, the unit must not be vented into a chimney into which a

solid fuel burning furnace is already being vented.

Before venting this furnace into a chimney, its condition must be

checked and repairs made, if necessary. Also, the chimney lining

and dimensions must conform to local and national codes.

1.6.2

Factory Built Chimneys

Oil fired furnaces are approved for use with “L” type vents. The unit

may also be used with an approved chimney of proper dimensions

and temperature ratings as specified in the installation code. Refer

to chimney manufacturer’s instructions for proper installation.

1.6.3

Draft Regulator

It is recommended that a draft regulator be installed in cases where

the draft is either high or variable due to external conditions. Follow

the instructions provided with the regulator.

1.6.4

Side-wall Venting

The heating unit is approved for side-wall venting. This system is

comprised of a model VTK-54 side-wall venter and a 4” insulated

vent pipe, model IFV-410, IFV-420. Refer to the installation

instructions provided with the venting system.

1.7

BLOCKED VENT SHUT-OFF DEVICE

(BVSO) FOR CHIMNEY VENTING -

OPTIONAL

It is imperative that this device be installed by a

qualified service technician.

A positive pressure venting system (Sealed

Combustion System or Direct Vent) must NOT use

the BVSO. Follow the instructions supplied with

the venting system.

This device is designed to detect the insufficient evacuation of

combustion gases in the event of a vent blockage. In such a case

the thermal switch will shut down the oil burner. The device will then

need to be re-armed MANUALLY.

Refer to the detailed instructions and wiring diagrams supplied with

the BVSO for the installation and wiring procedures. The length of

wires supplied with the unit is such that the safety device must be

installed between the flue outlet of the appliance and the draft

regulator, as indicated in the instructions.

It is also essential that the BVSO be maintained annually. For more

details refer to the instructions supplied with the device itself, as well

as Section 2 of this Manual.

1.7.1

BVSO Performance Test (If Installed)

The purpose of the following test is to check that the electrical outlet

on the furnace, designated to the BVSO, is functional.

1.

Start up the burner;

2.

Disconnect one wire of the BVSO;

3.

The burner must shut-off immediately, while the blower

continues to run to the end of the cool-down cycle.

If the test is not in line with the above, call a QUALIFIED SERVICE

TECHNICIAN.

Figure 8: BVSO mounting installation: Upflow with

vertical exhaust (OPTIONAL)

Figure 9: BVSO mounting installation: Upflow with

horizontal exhaust (OPTIONAL)

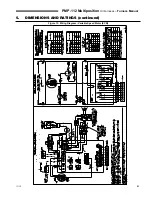

Figure 10: BVSO Wiring (OPTIONAL)