PMP

Oil Furnaces

–

Furnace Manual

670-000-003/1010

19

9

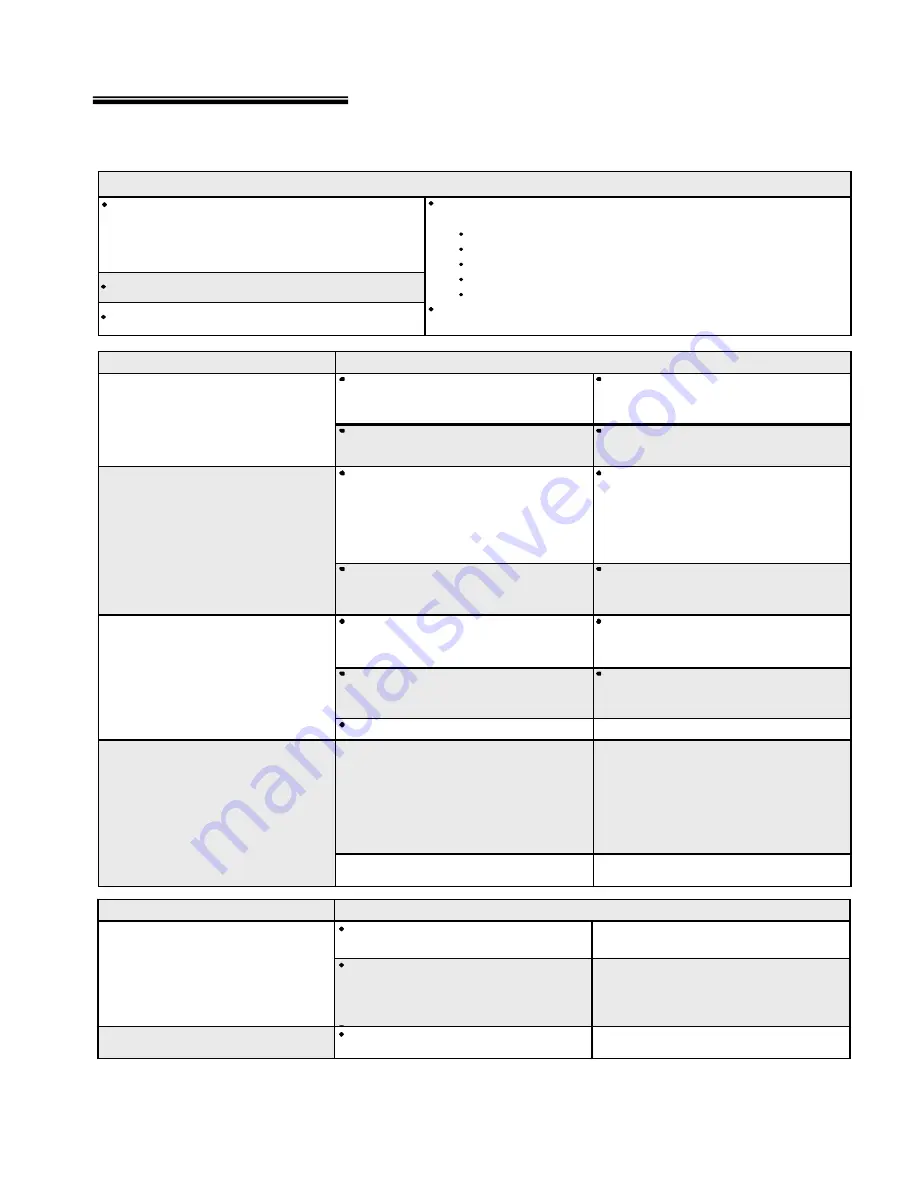

Troubleshooting

Check 120 volt supply to furnace. If there is no supply

To successfully service the oil furnace, you must

voltage, check fuses and service switch. CAUTION :

have these instruments :

When testing electrical equipment, always follow

smoke tester

standard electrical safety procedures.

carbon-dioxide (CO

2

) or oxygen (O

2

) analyzer

draft gauge (scale should read from -.01” w.c. to -.25” w.c.)

volt/OHM/milliamper multimeter

pressure gauge capable of reading 0-150 lb/sq. inch (for oil only)

Be familiar with these instruments as well as the burner

manufacturers recommended settings.

Before beginning these troubleshooting procedures, ALWAYS :

Make sure thermostat is calling for burner operation.

Check oil supply and make sure all valves are open.

Sym ptom – Burner

Check fuses and make sure service switch

is o n.

Check for vol tag e from primary re lay to

bu rner motor. Make sure th e prima ry relay

ha s not locke d o ut on safety.

Check for li ne volta ge into furnace jun ction

box.

Make sure the thermostat is calling for heat and

that the wiring to the thermostat is correct and t ight.

If the prima ry relay control is not po pping

out

th e

reset

b utton,

measure

the

milliamp erage at th e thermostat and se t the

heat-an ticipator

a ccord ingly.

A lso

check

wiring fr om the thermostat to the bu rner.

Check the alig nment of th e cad cell to

assure it is aimed at the fire.

Ch eck nozzle a nd electr ode position.

Check ig nition tra nsforme r ou tpu t

(Reference burner man ufa cturers

instructio ns) .

Check tube insertion and ali gnment.

Check n ozzle and electrode position

(Reference burn er ma nufacture rs

instructions).

Replace nozzl e.

Check

pump

pressure

(va ries

with

manu facturer and ap plicati on; se e burne r

manu al).

Check overfire draft.

1. Remove CA D cell leadwires from the f-f

terminals on the p rimary safety con tro l, then

sta rt burner. S hortly after burner starts,

place

a

temporar y

jumpe r

b etween

terminals f-f. Co nnect oh mete r a cro ss CA D

cell lead wires-re sistance should b e under

1,600 ohms.

3. Wi th burner off, check dark cel l resista nce

across

CA D

cell

leadwires.

Resista nce

shoul d b e gr eater than 20 ,00 0 o hms. If cel l

resistances

a re

differe nt

from

above,

reche ck wi ring and lo ca tion of cell , etc. If

ne cessary, rep lace p lug-in portion of ce ll.

2. Stop burne r a nd remove tempor ary jumpe r.

Possible correct ions :

To check CAD cell operation, use t he

following proce dure :

Burner m otor does not sta rt.

Unable to a chieve clean combustion

by se tting air adjustme nts .

Burner s hort c ycles or locks out on

prim ary re lay safety.

Symptom – Furnace blower

Check for 120V to the blower motor. If

present, replace motor.

Check wiring from Fan and Limit control. See

if blower motor will run when it is switched on

manually at the thermostat sub-base (if sub-

base is installed).

Blower short cycles on limit control.

Return ducts may be undersized.

Possible corrections :

Furnace blower will not start.