SCH & SCL

Oil Furnaces

–

Furnace Manual

670-000-006-1007

5

Connect fuel oil piping

General oil piping requirements

•

Location and installation of oil tanks, oil piping and burners

must follow:

•

NFPA 31, Standard for the Installation of Oil-Burning

Equipment.

•

In Canada, CSA B139, Installation of Oil-Burning

Equipment.

•

Local codes and regulations.

•

Information provided with burner and fuel pump.

•

If any part of fuel oil tank is above level of burner, an anti-

siphon device must be used to prevent flow of oil in case of

oil line break.

•

Support oil lines as required by codes.

•

Make tank connections with swing joints or copper tubing to

prevent breaking in case the tank settles. Make swing joints

so they will tighten as tank settles. Non-hardening pipe joint

compounds should be used on all threads.

Do not use Teflon tape as an oil pipe sealant. It

can cause valves to fail, creating hazards. Use

only flare fittings. Do not use compression fittings.

Failure to comply could result in severe personal

injury, death or substantial property damage from

oil leakage and/or fire hazard.

•

Underground pipe must be run in a casing to prevent oil

leaking into ground or under floor. Check local codes for

information.

Oil piping connection at burner

•

Connect oil line to burner using a flare fitting.

Use of any connection other than a flare fitting at

the oil connection to the burner could result in a

fuel oil leak, with the potential for severe personal

injury, death or substantial property damage.

•

See local codes for appropriate arrangement and piping of

filter, control valves, etc. connecting to oil tank.

•

Refer to burner manual for oil system requirements. Verify

that suction lift does not exceed stated limit. Where lift

exceeds limit for a one-pipe system, use a two-pipe system

as directed in burner manual.

Electric shock hazard. Can cause severe

personal injury or death if power source, including

service switch on furnace, is not disconnected

before installing or servicing.

6

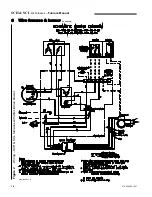

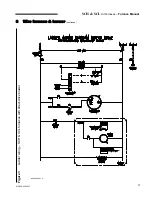

Wire furnace & burner

Wire burner

The burner harness is factory-wired to the furnace at the factory.

Plug the burner harness into the mating burner connector to wire

the burner. Refer to the wiring diagram on pages 16 and 17 for

further information.

Install and wire thermostat / shut-off

system

Mount the room thermostat on an interior wall in the natural

circulating path of room air. Do not locate the thermostat so it is

exposed to cold air infiltration, drafts from windows or doors, air

currents from supply or return air registers, behind obstructions,

on a shelf, in a closet, or in a corner.

Ensure that the thermostat will not be exposed to heat from a

nearby fireplace, radio, television, lamp or rays from the sun. Do

not mount the thermostat on a wall over a supply or return duct,

chimney or vent.

WARNING

Wire thermostat to the vent terminal pressure switch and to the

furnace electrical box (refer to wiring diagram). Set thermostat

anticipator as shown on wiring diagrams on pages 16 and 17.

Connect power wiring

All wiring must conform to:

•

National Electrical Code, ANSI/NFPA 70, latest edition and

any additional national, state or local codes.

•

In Canada, CSA C22.1 Canadian Electrical Code Part One

and any local codes.

•

Wiring must be N.E.C. Class 1. If original wire as supplied

with furnace must be replaced, type 105° C wire or equivalent

must be used. Supply wiring to furnace must be sized for the

load required (see Section 12).

•

Provide electrical ground at furnace as required by codes.

Connect 120 VAC/60 Hertz, single phase separate electrical line

from the main house panel to the power leads in the furnace

electrical box as shown on wiring diagram, pages 12, 13, 14 and

15. Provide a fused disconnect in the power wiring, following all

local codes.

Ensure the wire size and type are adequate for the electrical load

(see Section 12 and furnace nameplate for value).

Limit control

The furnace is equipped with a fan switch/limit control. This

control limits the air leaving the heat exchanger to 200° F or less.

The fan switch continues fan operation until the air drops to a

preset temperature. For most installations, set the blower ON

setting at 110° F and blower OFF setting at 90° F. If a longer cool

down period is desired, lower the OFF setting.

WARNING

WARNING

15

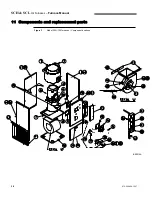

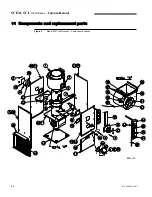

Summary of Contents for SCH High Boy

Page 12: ...SCH SCL Oil Furnaces Furnace Manual 12 670 000 006 1007...

Page 13: ...SCH SCL Oil Furnaces Furnace Manual 670 000 006 1007 13...

Page 14: ...SCH SCL Oil Furnaces Furnace Manual 14 670 000 006 1007...

Page 25: ...SCH SCL Oil Furnaces Furnace Manual 670 000 006 1007 COMPONENTS AND REPLACEMENT PARTS 25...

Page 39: ...SCH SCL Oil Furnaces Furnace Manual 670 000 006 1007 X40132 Rev D 39...