Installer’s Information Manual

Page 17

C22.1 and local codes. Use Type T (63 degrees C rise)

wire or equivalent.

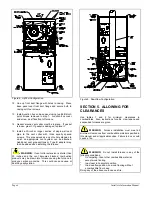

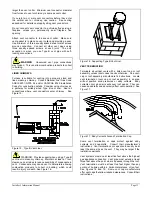

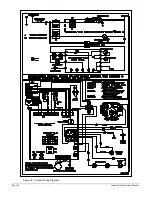

Figure 21. Field Wiring Diagram.

24-VOLT WIRING

Select a location for the room thermostat on a draft-free

interior wall that is away from supply and return air

registers, lights, television, direct sunlight, or other heat

sources.

Install thermostat following field wiring diagram in Figure 21

and thermostat manufacturer's instructions. Thermostat

wire should be 18 AWG wire for best results. NOTE: For

proper cooling operation, "Y" wire must be connected to the

Control. “Y” wire controls cooling speed blower operation.

Set the thermostat's heat anticipator following instructions

provided with the thermostat. This furnace will provide an

820 ohm load for electronic thermostats.

CAUTION: Unapproved 24 VAC accessories that draw

power from the furnace's transformer should not be

installed on this furnace. Addition of such accessories may

cause improper furnace operation and limit transformer life.

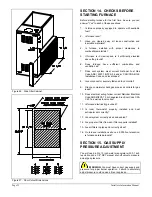

SECTION 11. SEQUENCE OF

OPERATION

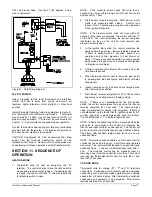

HEATING MODE

1. Thermostat calls for heat by energizing the “W”

terminal. The control checks to see the limit switch is

closed and pressure switch is open. If pressure switch

is closed, the control will flash “4” and wait indefinitely

for pressure switch to open.

NOTE: If the pressure switch opens (for more than 2

seconds) five times within a single call for heat, the control

will lock out for 1 hour.

2. Draft inducer relay is energized. Draft inducer motor

starts and pressure-switch closes. Control runs

inducer for a 15 second pre-purge time, then proceeds

to the ignition trial period.

NOTE: If the pressure switch does not close within 30

seconds of the inducer energizing, the control will flash “2”

on the LED. The control will leave the inducer energized

indefinitely as long as the call for heat remains and

pressure switch is open.

3. In the ignition trial period, the control energizes the

spark and main gas valve. Inducer remains energized.

If flame is sensed within 7 seconds, spark is de-

energized and control proceeds to heat blower on

delay. If flame is not sensed within 7 seconds, control

de-energizes the gas valve and proceeds with ignition

re-tries (see note below).

4. Control energizes main blower 20 seconds from the

time flame is sensed.

5. When thermostat call for heat is removed, gas control

is de-energized then post-purge and blower off delay

timing begin.

6. Inducer remains on for a 45 second post-purge period

after thermostat is satisfied.

7. Main blower remains energized for 90 to 180 seconds

depending on heating blower off-delay setting.

NOTE: If flame is not established for the first ignition

period, the control de-energizes the gas valve, the inducer

remains energized for 15 seconds. The spark and gas

valve are energized for another trial of ignition. If flame is

not established on the fourth trial for ignition (initial try & 3

re-tries), gas valve is de-energized and goes into lockout.

The control flashes a “1” to indicate failure lockout.

NOTE: If flame is sensed longer than 4 seconds while the

gas valve is de-energized, the control will energize the

inducer and indoor blower on heat speed. The control will

go into lock-out but will still respond to open limit and flame.

The Flame LED will flash rapidly when lock-out is due to

undesired flame.

NOTE: This furnace will not initiate a call for heat or call for

continuous fan while in lock-out. A call for cooling operates

as normal. The control will still respond to an open limit and

undesired flame. Lock-out will automatically reset after 1

hour. The furnace's control can be manually reset by

removing power from the control for more than 1 second or

removing the thermostat call for heat for more than 1 and

less than 20 seconds.

COOLING MODE

Thermostat calls for cooling ("R", "Y" and "G" terminals

connected). Condensing unit contactor closes, energizing

condensing unit. Control energizes main blower on cooling

speed after a 6 second delay. After thermostat is satisfied,

condensing unit contactor is de-energized. Main blower

remains energized for 45 seconds.