Installer’s Information Manual

Page 25

SECTION 18. DERATING FOR HIGH

ALTITUDE

At higher altitudes, the density of the air is reduced.

Therefore, for proper combustion, the quantity of gas

burned in the furnace must also be reduced. This is called

derating. Furnaces must be derated when installed at

altitudes greater than 2,000 feet above sea level.

Derating the furnace by adjusting the manifold pressure

lower than the range specified in the Section 16, "Manifold

Pressure Adjustment" is considered to be an improper

procedure.

At elevations above 2,000 feet, the furnace must be

derated 4% for each 1,000 feet above sea level. It is the

installer’s responsibility to see that the furnace input rate is

adjusted properly. Derating must be achieved by reducing

the size of the main burner orifices. Choose the proper

orifices for your altitude and gas heating value from orifice

size Table 8 or 9. In Canada, high-altitude models may be

available which are rated for 2,000 to 4,500 feet above sea

level.

SECTION 19. DETERMINING

CORRECT ORIFICE SIZE

Table 7 shows original factory installed orifice sizes. See

Table 8 or Table 9 to determine correct orifice size. Natural

gas and propane (LP) gas orifice kits are available through

your supplier. Individual orifices are also available in

convenient lot sizes. To assure proper performance, use

only manufacturer supplied orifices.

Table 7. Factory Installed Orifice Sizes.

FURNACE MODEL

NATURAL

GAS

PROPANE

(LP)

U.S. (except NOx models)

2.15 mm

1.30 mm

U.S. (California NOx models)

2.10 mm

NA

CAN. (0 to 2000 feet)

2.15 mm

1.30 mm

CAN. (2001 to 4500 feet)

2.05 mm

1.20 mm

Table 8. Natural Gas Orifice Size.

ELEVATION

Gas

Up

2001 3001 4001 5001 6001** 7001** 8001** 9001**

Heat* to to to to to to to to to

Value

2000 4000 4000 5000 6000 7000 8000 9000 10000

Btu/cu. ft.

Feet

Feet

Feet Feet Feet Feet Feet Feet Feet

800-849

2.35mm

2.30mm

2.30mm

2.25mm 2.20mm 2.20mm 2.15mm 2.10mm 2.05mm

850-899

2.30mm

2.25mm 2.20mm 2.20mm 2.15mm 2.10mm 2.10mm 2.05mm 2.00mm

900-949

2.25mm 2.20mm 2.15mm 2.15mm 2.10mm 2.05mm 2.05mm 2.00mm

1.95mm

950-999

2.20mm 2.15mm 2.10mm 2.05mm 2.05mm 2.00mm

1.95mm

1.95mm

1.90mm

1000-1049

2.15mm 2.10mm 2.05mm 2.05mm 2.00mm

2.00mm

1.95mm

1.90mm

1.85mm

1050-1099 2.10mm

2.05mm

2.00mm

2.00mm

1.95mm

1.90mm

1.90mm

1.85mm

1.85mm

1100-1149 2.05mm

2.00mm

2.00mm

1.95mm

1.95mm

1.90mm

1.85mm

1.85mm ------

1150-1199

2.00mm

1.95mm

1.95mm

1.90mm

1.90mm

1.85mm ------ ------ ------

*At standard conditions: 30.0 inches Mercury, 60°F, Saturated.

**Above 6000 feet, a separate high altitude kit must be used.

NOTE: Shaded orifices above are available separately.

Table 9. Propane (LP) Gas Orifice Size.

ELEVATION

Gas

Up 2001 3001 4001 5001 6001* 7001* 8001* 9001*

Input to to to to to to to to to

(Btu/Hr) 2000 3000 4000 5000 6000 7000 8000 9000 10000

Feet Feet Feet Feet Feet Feet Feet Feet Feet

40,000-140,000 1.30mm 1.25mm 1.25mm 1.20mm 1.20mm 1.20mm 1.15mm 1.15mm 1.10mm

*Above 6000 feet, a separate high altitude kit must be used.

NOTE: All orifices above are included in propane gas orifice kit.

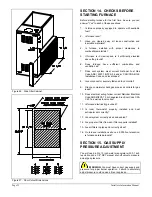

SECTION 20. CHANGING MAIN

BURNER ORIFICES

WARNING

: To prevent electrical shock and gas

leaks, turn off electrical power and gas before changing

orifices.

Follow this procedure:

1. Set room thermostat to its lowest or off setting.

2. Turn off electricity at electrical disconnect switch next

to furnace.

3. Turn off equipment shut-off valve in gas supply line just

ahead of furnace.

4. Turn gas control switch to “OFF” position.

5. Starting with burner farthest from gas control, remove

burner screws and burners. Note how the burner

mounting flange of burners farther from the gas control