Installation

en

Installation and operating instructions Wilo-Control MS-L

23

GL

WSK

-P2

WSK

-P1

SL

10

9

8

7

6

5

4

3

2

1

HW

HW

GL

WSK

6

5

4

3

2

1

3

3

Control MS-L1.../MS-L...-O

WSK

6

5

2

1

3

Control MS-L1...-LS

Control MS-L2.../MS-L...-O

WSK

-P2

Sensor

+ ln

Sensor

+ ln

WSK

-P1

10

9

4

3

2

1

3

Control MS-L2...-LS

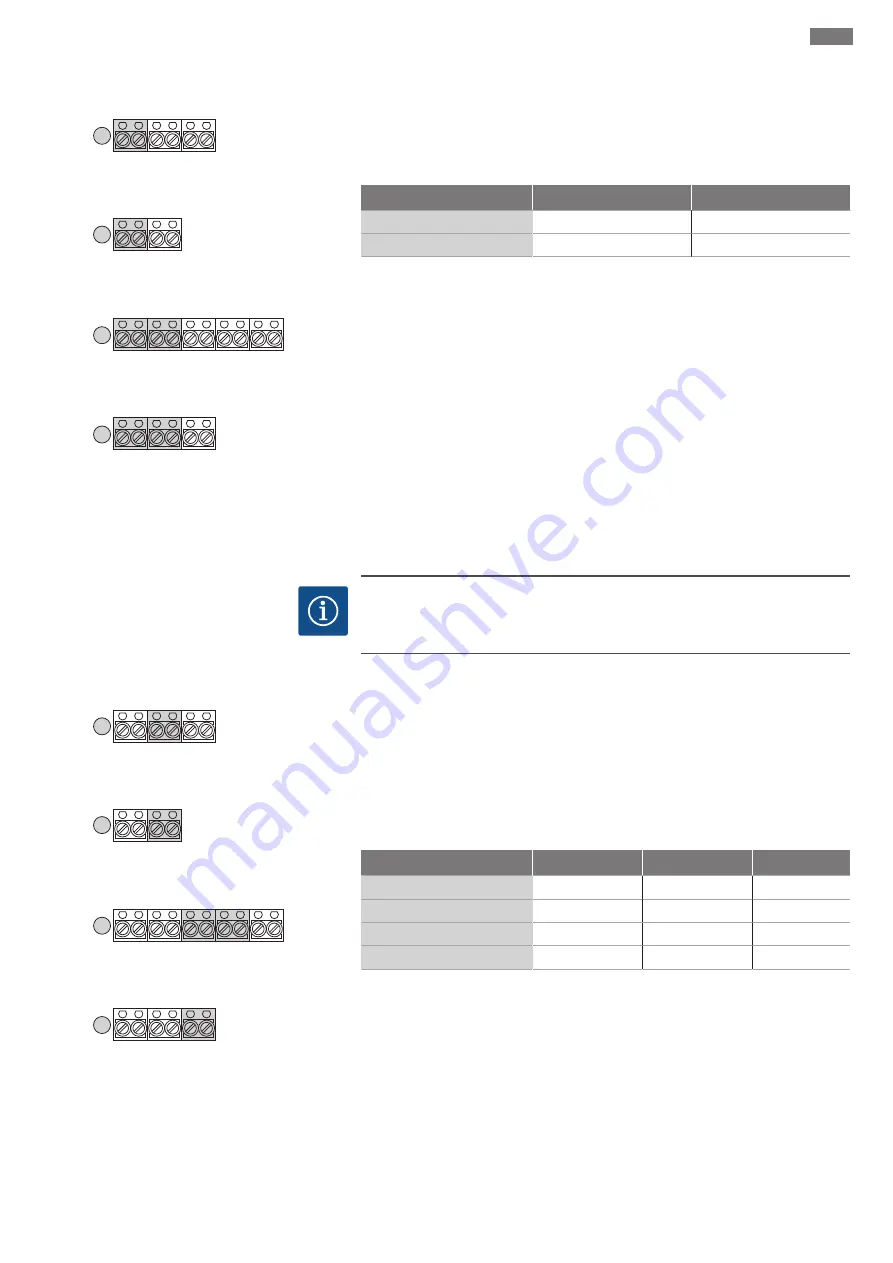

Fig. 11:

Terminal strip sensors: thermal motor

monitoring

Connect one thermal motor monitoring device with bimetallic strips per pump. Do not

connect a PTC sensor!

Insert the connection cables laid by the customer through the threaded cable glands

and secure. Connect the wires to the terminal strip according to the connection dia-

gram.

Switchgear

Pump 1

Pump 2

Control MS-L1...

Terminal 1/2

Control MS-L2...

Terminal 1/2

Terminal 3/4

NOTICE! If a winding monitor is connected, remove the converter bridge installed at

the factory!

6.5.8

Connection of signal transmitter

for level control device

NOTICE

Do not apply external voltage!

An external voltage which is applied destroys the component.

GL

WSK

-P2

WSK

-P1

SL

10

9

8

7

6

5

4

3

2

1

HW

HW

GL

WSK

6

5

4

3

2

1

3

3

Control MS-L1.../MS-L...-O

WSK

6

5

2

1

3

Control MS-L1...-LS

Control MS-L2.../MS-L...-O

WSK

-P2

Sensor

+ ln

Sensor

+ ln

WSK

-P1

10

9

4

3

2

1

3

Control MS-L2...-LS

Fig. 12:

Terminal strip sensors: Level detection

connection

Control MS-L.../MS-L...-O

Connect float switch for the level detection. Level detection with a level sensor or elec-

trodes is not possible!

Control MS-L...-LS

A rod float sensor is used for the level detection. The sensor is installed in the lifting

unit at the factory. Level detection with float switches or electrodes is not possible!

Insert the connection cables laid by the customer through the threaded cable glands

and secure. Connect the wires to the terminal strip according to the connection dia-

gram.

Switchgear

Base load (GL)

Peak load (SL)

Sensor

Control MS-L1.../MS-L1...-O Terminal 3/4

−

−

Control MS-L1...-LS

−

−

Terminal 5/6

Control MS-L2.../MS-L2...-O Terminal 5/6

Terminal 7/8

−

Control MS-L2...-LS

−

−

Terminal 9/10