English

Installation and operating instructions Wilo-SiFire System

33

6.2 Description of the product

6.2.1 The booster - See fig. 3 – Position:

1 Gate valve

2 Connection for local sprinkler

3 Double pressure switch circuit main pump

4 Non-return valve

5 Flexible vibration-damping sleeves for diesel

pump

6 Connection for recirculation circuit with dia-

phragm

7 Divergent cone on discharge side main pump

8 Pump/motor coupling with spacer

9 Main pump electric/diesel motor

10 Coupling guard

11 Main pump control panel

12 Jockey pump control panel

13 Discharge manifold

14 Connection for setting of flow meter option

15 Fuel tank (for diesel pump)

16 Connection for priming circuit of main pump

17 Main pump

18 Jockey pump

19 Tank for fuel leakages

20 Fuel tank vent valve

21 Fuel level gauge

22 Drain for cleaning of deposit in fuel tank

23 Drain for cleaning of deposit in tank for fuel

leakage

24 Fuel filler cap

25 Connection for motor return pipe

26 Connection for fuel supply to the motor

27 Level gauge for fuel

6.2.2 Control box

• Ensure complete automatic operations of each

pump and associated functions

• Waterproof, protection class IP 54.

6.3 Function of the product

The operational logic for the fire extinguishing

unit is based on the cascade calibration of the

pressure switches for pump starting. The jockey

pump of pressure boosting is the first to start and

maintains the system full of water and under pres-

sure. It starts when the pressure drops in the sys-

tem. Start and stop control is set up via the

suitably calibrated pressure switch.

When a larger quantity of water is requested, due

to the opening of one or more circuits or due to a

broken sprinkler, pressure decreases in the sys-

tem. This drives the main pump to start.

For systems with more than one pump, if the main

electric pump does not start, due to electricity

problems for example, the drop in pressure will

activate the standby pump pressure switch which

starts the diesel engine. In some cases, two or

more electric pumps could be used.

Once the sprinkler circuit or the gate valve that

supply the sprinkler system is closed, the system

reaches the maintaining pressure of the installa-

tion; it will be necessary to press the –Stop– but-

tons on panels to stop the main pump and standby

pump. The jockey pump is automatically stopped.

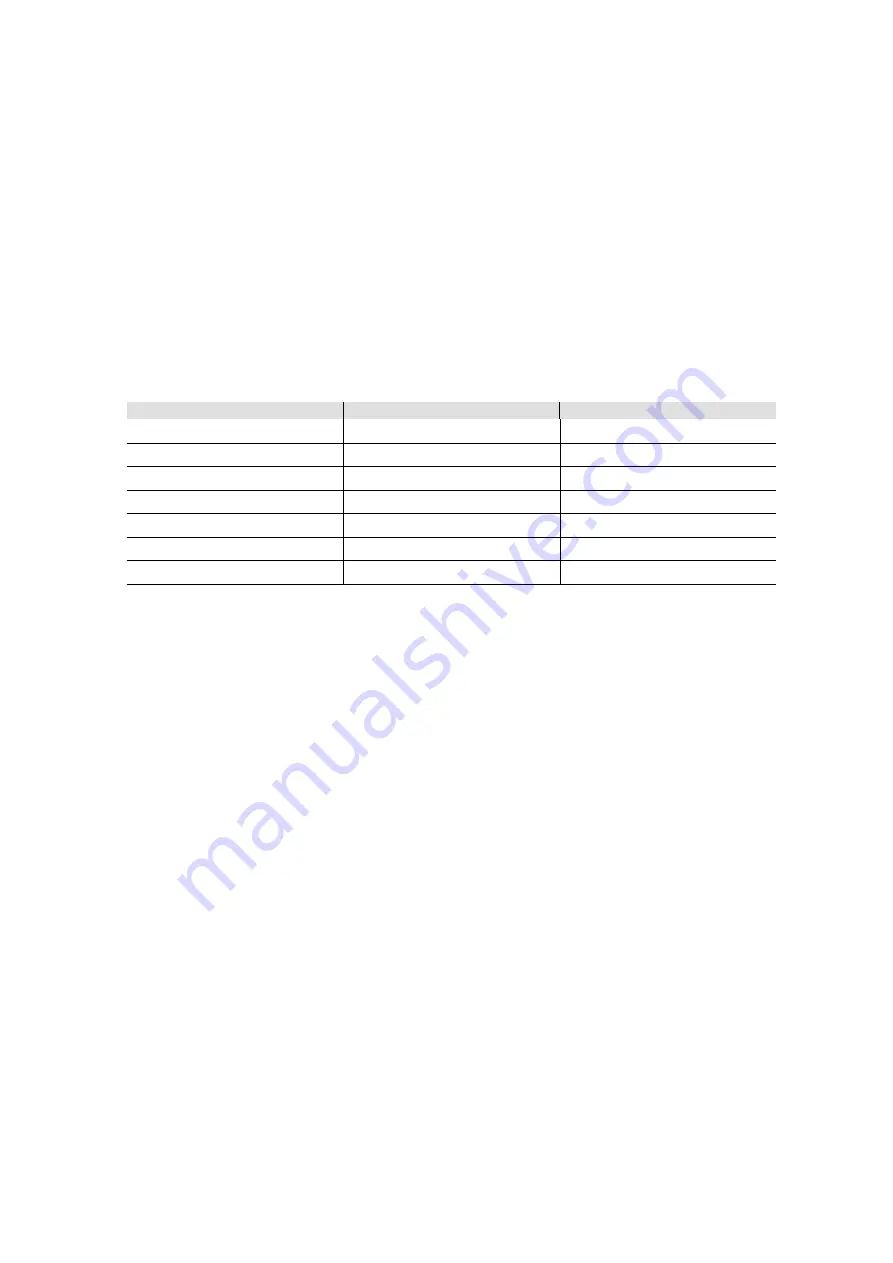

Æ discharge of main pump

Æ Accessories

Æ Manifolds

DN32

DN50

DN65

DN40

DN65

DN65

DN50

DN65

DN80

DN65

DN80

DN100

DN80

DN100

DN125

DN100

DN125

DN150

DN125

DN150

DN200

Summary of Contents for SiFire EN 100/200-205-45 E

Page 2: ...Fig 1 Fig 2a A 2 2 E B C D ...

Page 3: ...Fig 2b Fig 3 21 25 26 13 11 12 19 15 22 27 20 24 23 2 1 14 4 16 7 5 6 10 18 17 9 9 10 8 3 ...

Page 4: ...Fig 4 Fig 5 ...

Page 5: ...Fig 6a 3 5 D D 4 D 2 3 C min max 1 8 m s Fig 6b min 3 5 D D 4 D max 2 m 2 3 C max 1 8 m s ...

Page 6: ...Fig 7 Fig 8 max 3 2 m min A B C D 2 4 5 6 3 8 7 1 ...

Page 7: ...Fig 9a Fig 9b A B C D 800 800 800 ...

Page 8: ...Fig 1a Fig 9a variant Fig 9b variant A B C D 800 800 800 ...

Page 9: ...Fig 10 Fig 11 1 2 1 2 1 ...

Page 10: ......