- 37 -

Wheels and Tires

Be sure to use only the fasteners matched to the cone angle of your wheel

(usually 60 or 90 degrees).

The proper procedure for attaching your wheels is as follows:

1. Start all bolts or nuts by hand to prevent cross threading.

2. Tighten bolts or nuts in the sequence detailed below.

3. The tightening of the fasteners should be done in stages. Following

the recommended sequence, first tighten all the fasteners to 20-25

ft.lb., and finally to the required torque based on the size of the

wheel nut (see chart).

4. Wheel nuts/bolts should be torqued before first road use and after

each wheel removal. Check and retorque after the first 50-100

miles.

Torque Requirements

Wheel Nut Torque Guide

Nut Size

Torque (ft.lbs.)

1/2”-20 (Cone)

90-120

9/16”-18 (Cone)

90-120 Steel

9/16”-18 (Cone)

120-140 Aluminum

(Note 1)

5/8”-18 (Cone) 190-210

5/8”-18 (flanged nut)

275-325 (One-Piece)

(Note 2)

5/8”-18 (flanged nut)

140-160 (Two-Piece)

Note 1

: This is when nut is used in conjuction with the reinforcing ring.

Note 2

: This two piece flange nut is used on the Alcoa Aluminum Dual

wheel

application.

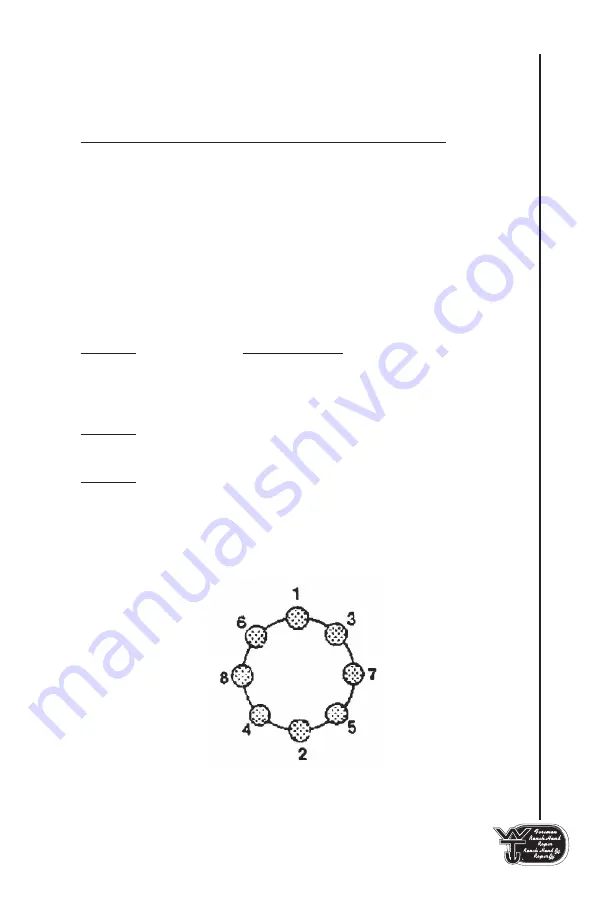

TORQUE

SEQUENCE

8-BOLT

Summary of Contents for GOOSENECK LIVESTOCK

Page 40: ... 40 Electrical System Electric Hydraulic Brake Application System ...

Page 43: ... 43 Electrical System Electric Brakes Wiring Diagram ...

Page 44: ... 44 Electrical System Vacuum Hydraulic Brakes Wiring Diagram ...

Page 75: ... 75 ...

Page 78: ... 78 ...

Page 79: ... 79 ...