© by WilTec Wildanger Technik GmbH

Item 34207

Page 5

07 2021

-1

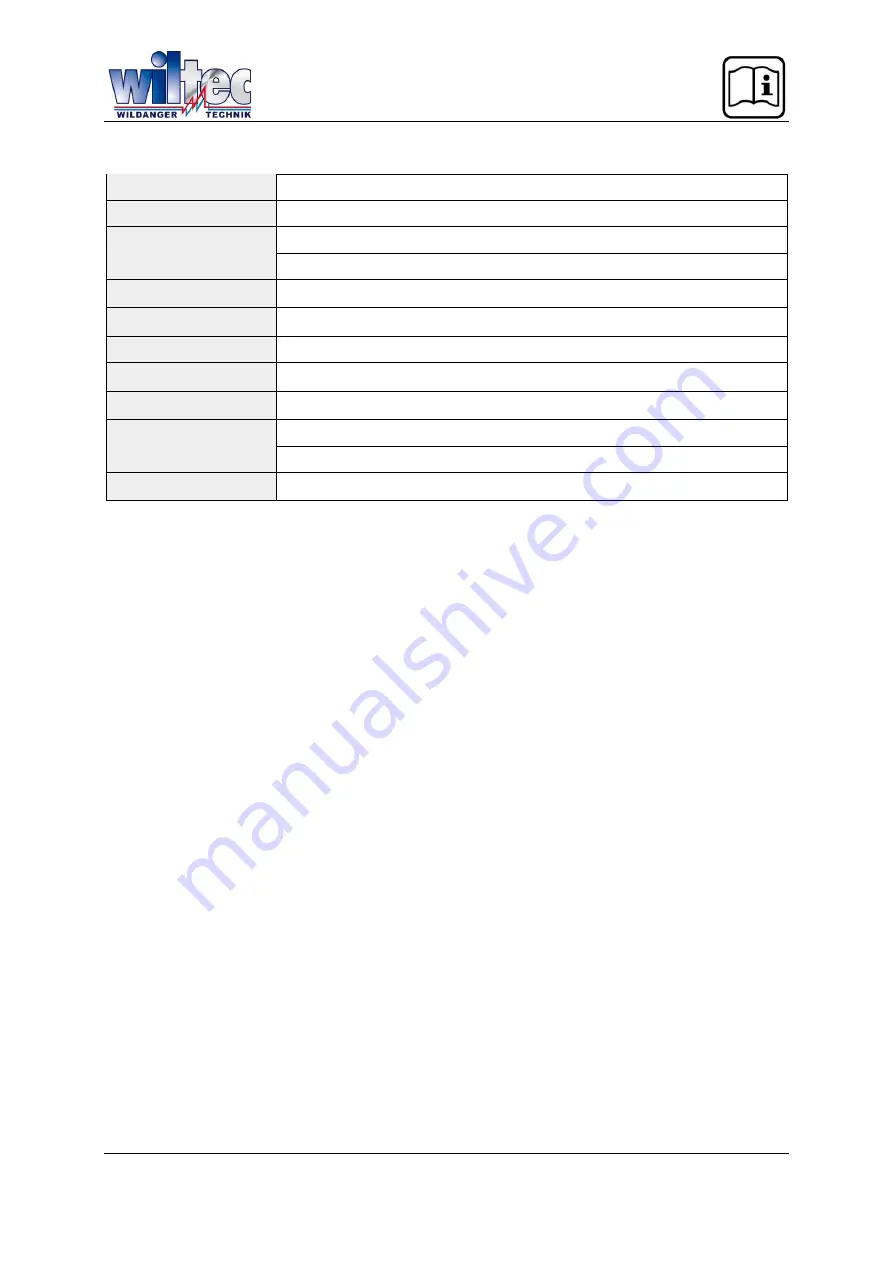

Technical specifications

Type

Two-cylinder air compressor with tank and casing

Power

(W)

190 (¼ hp)

Rotation speed

(rpm)

1450

–1700

Flow rate

(

ℓ

⁄

min

)

30

–40

Pressure range

(

㍴

)

0

–4

Weight

(

㎏

)

11

Capacity

(ℓ)

3

Size

(

㎜

)

320×135×350

Suitable nozzles

(

㎜

)

0.2

–1.0

Sound level

(dB (A))

approx. 45

Length of cable

(m)

1.9

Hose connection

(

㎜

)

9.5

1 (⅛″)

User notes

•

The compressor has a 9.51

mm (⅛″) outlet with external thread which can be effortlessly

changed to ¼

″. The matching adapter is not included in the delivery.

•

When the compressor is connected by the hose to the airbrush gun, it can be connected to the

mains and switched on.

•

The maximum pressure is displayed the pressure gauge, the operating pressure can be ad-

justed by the pressure regulator.

•

The hose included in the delivery is air-tight. If the auto-stop mode is activated (repeatedly

switched on/off) any and all screw fittings and connections should be sealed by sealing tape.

Leakage check

•

Switch on the compressor and wait until the maximum pressure has built up and the auto-stop

function has been activated.

•

If there is no leakage, the pressure gauge should display nearly constantly the same range of

pressure.

•

A quick decrease of the range of pressure suggests that there is in fact a leakage.

•

It is of great importance to seal any leak as soon as possible in order to avoid any impact on

the capacity and efficiency of the compressor.

•

A leakage leads to the auto-stop and auto-start constantly being switched on and off.

Difference between maximum pressure and operating pressure

•

The maximum pressure is the highest possible pressure that a compressor is able to generate.

•

The maximum pressure is the pressure measured only inside the compressor itself.

•

Once the maximum pressure has been reached, the compressor switches off (auto-stop), and

as soon as the pressure starts to decrease, it switches on again (auto-start).

•

On the outlet of the compressor, there is a lower pressure. What remains is the pressure that

you actually work with. The operating pressure may vary according to the connected airbrush

gun.