© by WilTec Wildanger Technik GmbH

Item 34207

Page 8

07 2021

-1

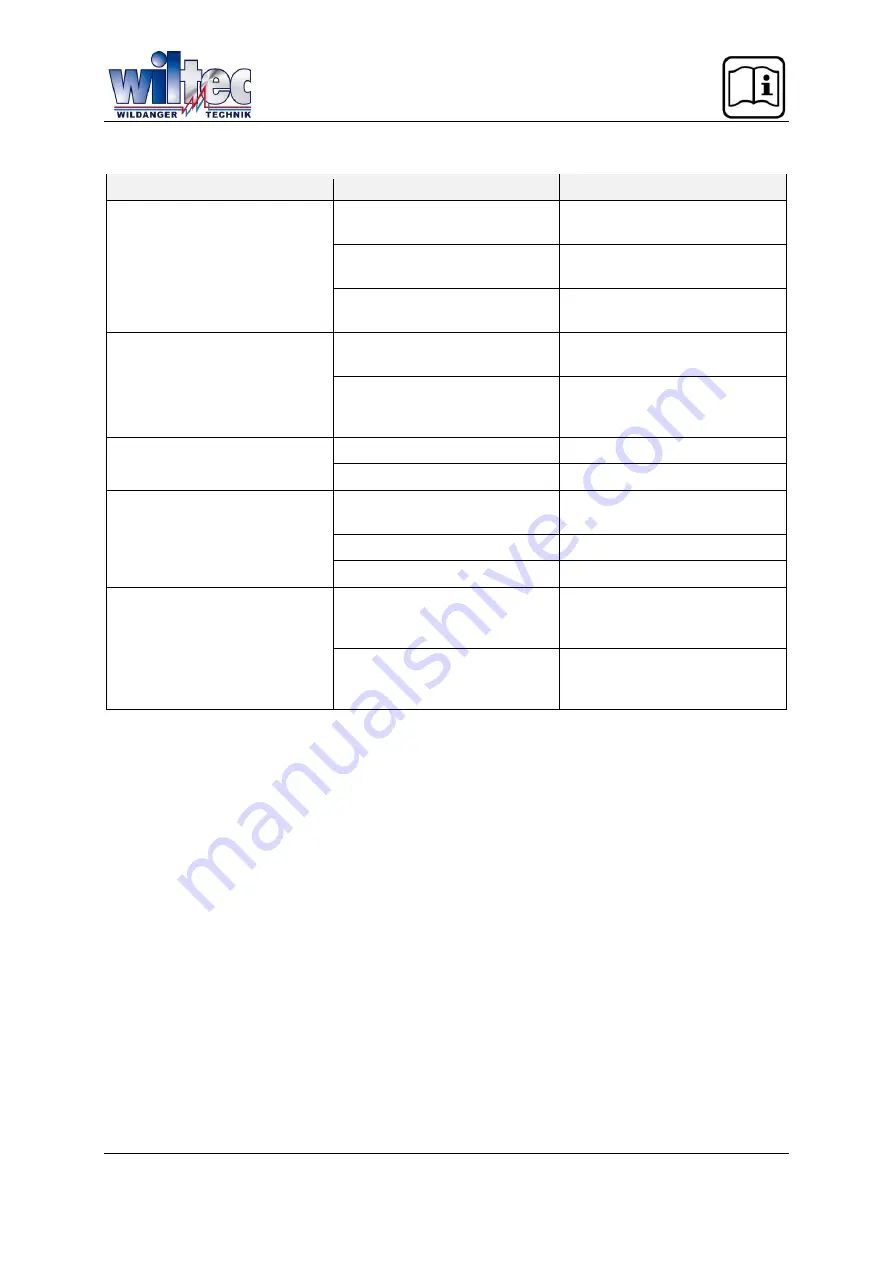

Troubleshooting

Problem

Cause

Solution

The engine does not run.

Damaged electric cables

Check electrical cable, replace it

if necessary.

Interior cable connections dam-

aged

Open rear cover, check interior

cable connections, repair them.

On/off switch does not function

Check on/off switch, replace it if

necessary.

The engine makes noises, but

does not run.

Outlet completely clogged or

closed

Unblock or open outlet.

Wrong direction of cylinder valve

after first assembly/disassembly

made by the user

Reinstall cylinder valve and place

it in the right direction.

Engine runs, but makes noises. Bearings are loose or damaged Replace bearings.

Screws in connecting rod loose

Tighten or replace screws.

Airbrush-gun does not function

properly,

insufficient

blowing

pressure.

Air connection not tight.

Seal air connection with insulat-

ing tape.

Air hose torn off

Re-mount the air hose.

Screws of cylinder cover loose.

Tighten screws.

Engine runs smoothly, but gener-

ates no air pressure or no suffi-

cient airflow.

Valve screws and diaphragm

screws loose or in wrong posi-

tion.

Open front cover, tighten screws,

and place the diaphragm screws

in right position.

Valve destroyed because of too

long a work with too high a pres-

sure.

Replace valves or cylinder cover.