© by WilTec Wildanger Technik GmbH

Item 61055

Page 7

10 2021

-1

◦

Children and pregnant women are not allowed to enter the workspace.

◦

At the workspace, it is not allowed to eat, drink, or smoke.

◦

Contact with or inhaling of the sanded dust (e.g., lead-based coating material) can cause

damage to health of users. Always wear properly sized personal protection equipment such

as a dust mask and use a dust bag while sanding.

•

The power cable must be kept away from the moving parts of the machine.

•

Wear protection goggles, especially while sanding above your head.

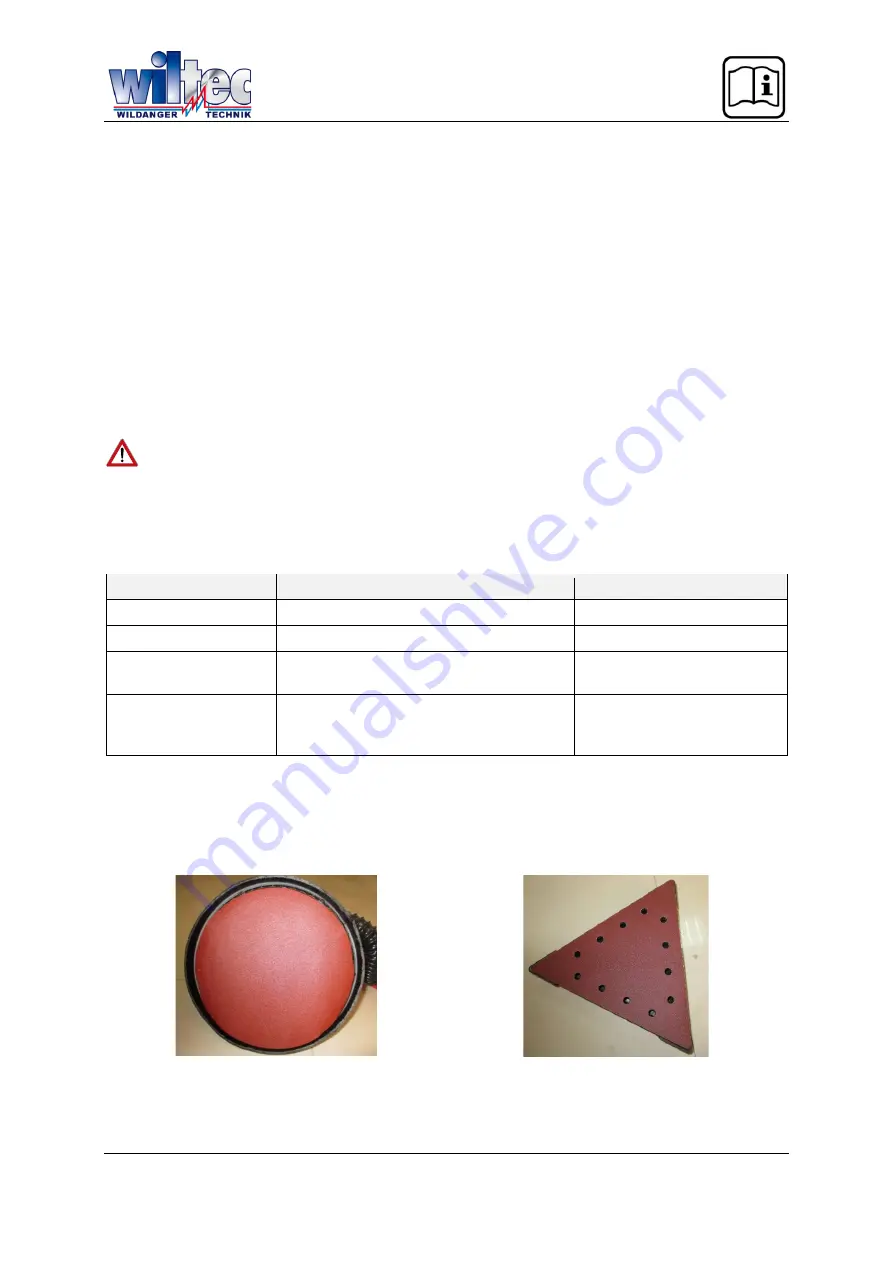

Abrasive disc selection

The drywall sander is shipped with 6 pieces of sanding paper (80/100/120/150/180/240 grit). This abra-

sive is suitable for most applications. Abrasive discs of 120 grit and 240 grit are available for situations

requiring a smoother finish.

Installation

Before repair or replacement of electric tool parts or accessories, be sure to pull out the plug from

the socket.

Sandpaper selection

According to the material and the grinding effect, select the appropriate sandpaper:

Material

Use

Grit

Pigment

Removal of pigments

40

Paint

Removal of remaining paint

60

Filling agent

Grinding bottom pigment (such as finishing

bottom)

80

Interstitial material

Brush paint, grinding residues

Drop-shaped or convex pigment residues

Flat bottom material for painting

100

120

180

Replacing sanding paper

Before installing the new sanding paper, you first need to clear dirt sticking to the grinding wheel by use

of a brush. The grinding surface adhesive disc has a layer of cloth so it can quickly and easily be in-

stalled. The surface grinding sandpaper is pressed into the adhesive disc.

Do

not

use the sander without a proper abrasive pad installed to prevent severe damage to the work.