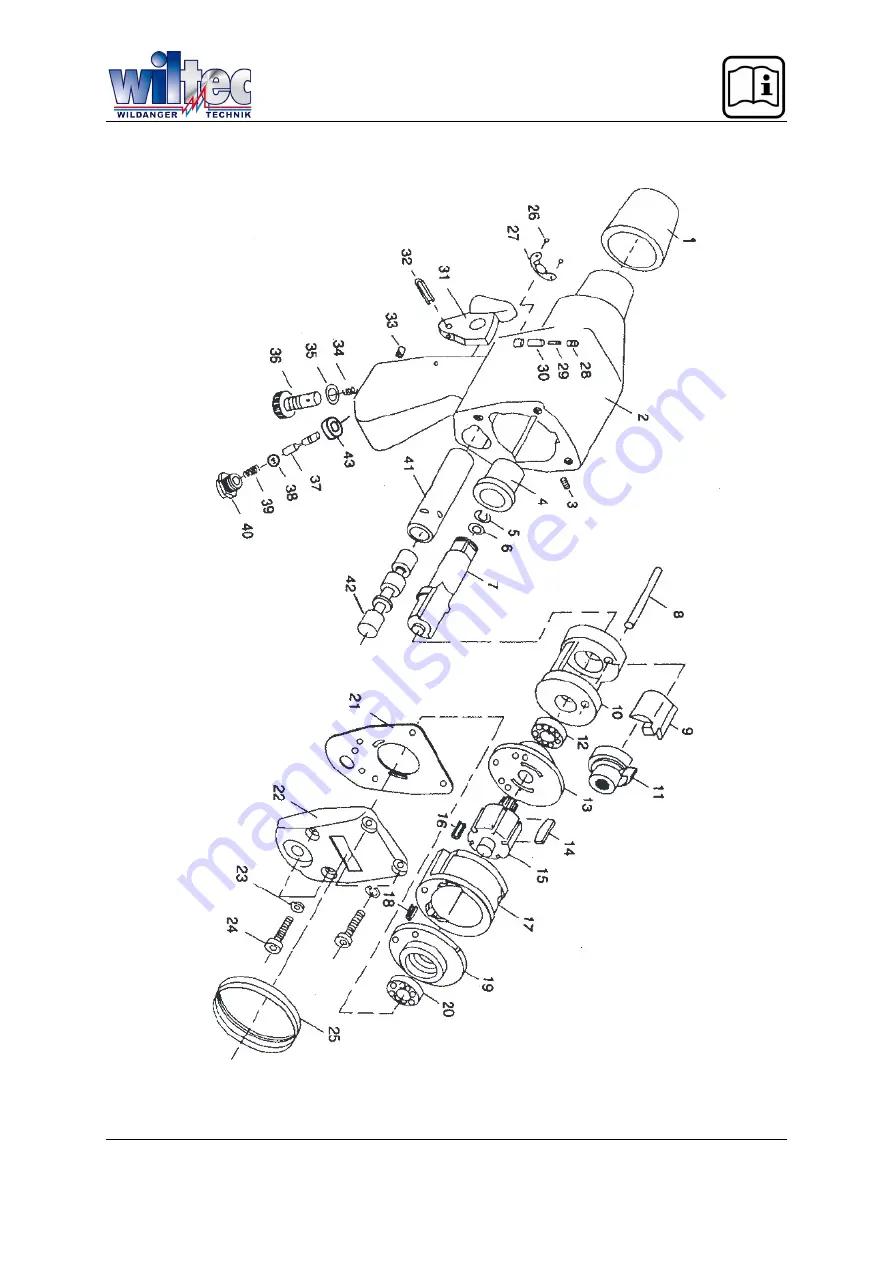

EXPLODED DRAWING

Warning!

Repairs must only be made by an authorized service partner or the manufacturer. Do not

open or disassemble the power tool.

© by WilTec Wildanger Technik GmbH

Seite 28

http://www.WilTec.de

http://www.aoyue.eu

http://www.teichtip.de