FUNCTIONAL DESCRIPTION

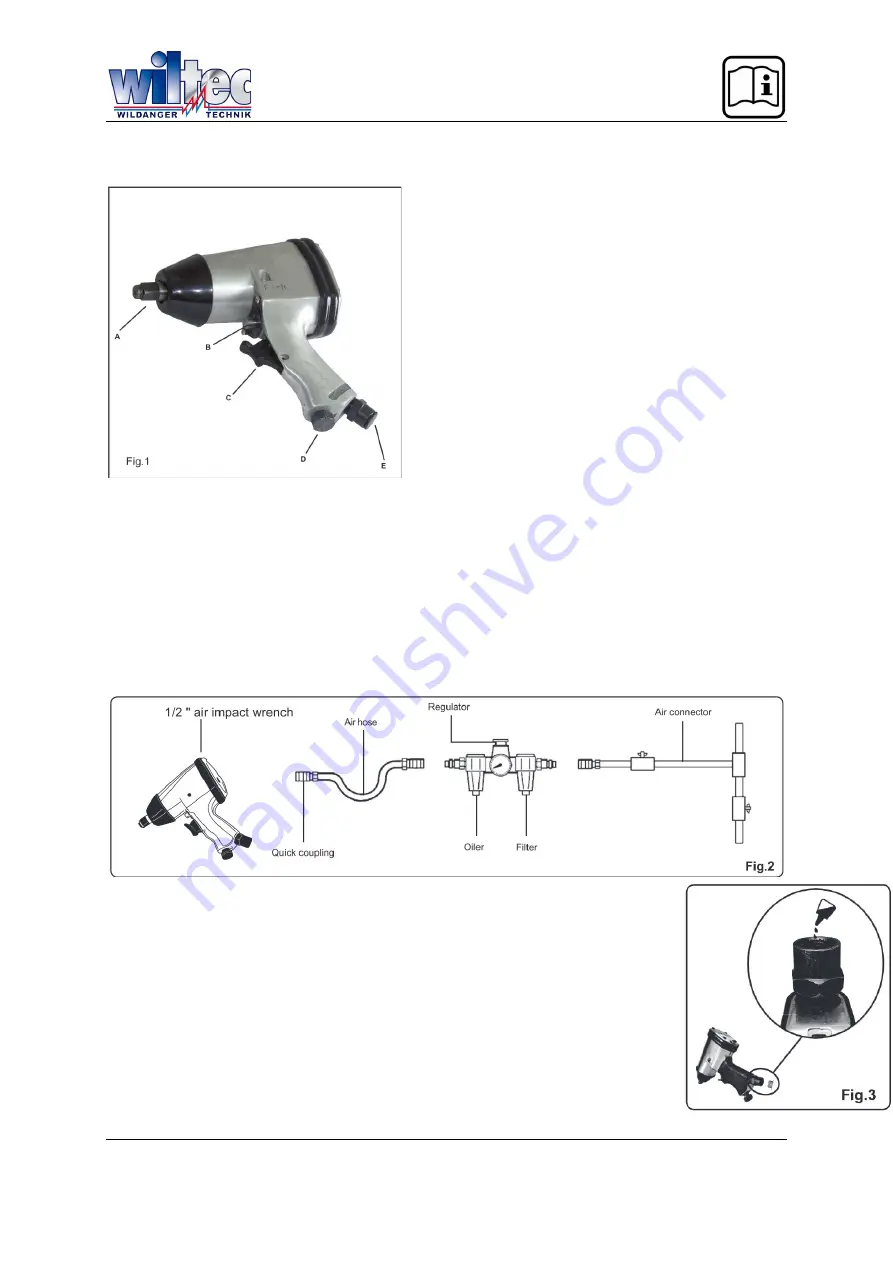

Major components of 1/2” Air Impact Wrench:

a) Anvil

b) Control Valve

c) Trigger

d) Air Regulator

e) Air Inlet

OPERATING PROCEDURES

SETUP AIR SOURCE

The 1/2” air impact wrench is designed to operate on clean, dry, compressed air, regulated at 90

PSI. The preferred system would include a filter, a pressure regulator and an automatic oiler lo-

cated as close to the tool as possible. Within 15 feet (4.5m) is ideal. Do not use bottled air or

gases. Please see below (Fig.2):

All compressed air contains moisture and other contaminants that can harm the

internal components of the tool. An air filter will remove most of these and signifi-

cantly extend the life of the tool. Ensure the in-line oiler has sufficient oil. If an in-

line oiler is not available, place 2 drops of oil into the tool’s air inlet at the begin-

ning of each workday. More than this will be expelled from the tool’s exhaust

during using (Fig.3).

© by WilTec Wildanger Technik GmbH

Seite 23

http://www.WilTec.de

http://www.aoyue.eu

http://www.teichtip.de