17

Single Phase Electrical Hookup

When connecting your machine to single phase

power, you may be connecting to either 115 or 230 volts,

depending upon the motor type provided. Local codes may,

or may not, permit the use of a plug type of connection for

your machine. Where a plug connection is permitted, the

following installation practices must be followed:

1. The plug used must be a grounding type of plug. That is,

on a 115 volt single phase connection, the plug must be a

three-prong plug with two flat, parallel blades for the power

wires and a single rounded or U-shaped prong for the

ground connection. On 230 volt single phase connections,

the lug must be a three prong plug with two flat blades in

tandem to carry the current, and a third round or U-shaped

prong for the ground connection.

2. The service branch to which the plug is connected must

be a branch with a separate ground wire so the grounding

prong of the plug can be connected to ground effectively.

Note: Local electrical codes in many jurisdictions

DO NOT ALLOW THE USE OF PLUG TYPE CONNECTIONS

FOR SINGLE PHASE POWER WHEN THE MACHINE IS USED

IN A COMMERCIAL OR INDUSTRIAL ESTABLISHMENT.

In these cases you must connect your machine to

the service branch using a hardwired junction box connec-

tion.

Motor Rotation

The motor should be turning counterclockwise, the

belt sander should be moving downward, and the disc

sander should be turning clockwise. These motors are

wired at the factory for correct rotation.

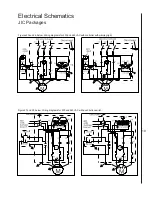

Voltage Conversion

Single phase machines are pre-wired for 115V or

230V per customer request. If it becomes necessary to

change the voltage, remove the back cover from the base

and place the machine on its side. Remove the terminal

cover from the motor. Rewire the motor according to the

motor connection diagram, (Figure 32 or, Figure 33).

Different electrical plugs are required depending on which

voltage you select. This completes the voltage conversion

process.

Circuit Protection

Where the service branch is protected with a fuse or

circuit breaker that has too high a value to offer protection to

the motor supplied, a fuse or circuit breaker box should be

used at the point where the machine connection is made

and the time delay fuse or circuit breaker should be a value

just slightly higher than the maximum load current draw.

Three Phase Electrical Hookup

1. Be certain the power to the branch you are connecting is

off and locked out, so power cannot be reestablished acci-

dentally.

2. Connect the ground wires. These wires will be either

green, or green with a white stripe.

3. Connect the remaining three cable wires to the three

power wires in the service branch.

4. Reestablish the power to the branch.

Motor Rotation

The motor should be turning counterclockwise,

the belt sander should be moving downward and the disc

sander should be turning clockwise. If this is the case, the

machine can be considered wired correctly. If the motor is

not turning in the correct direction, take the following cor-

rective action:

1. Disconnect power in the branch again and be certain it

cannot be accidentally turned on while you correct the wir-

ing.

2. Reverse ANY TWO of the power wires to the machine.

3. Reestablish the power to the machine.

4. Turn the machine on. The motor should now be turning

in the correct direction.

Voltage Conversion

Three phase machines are pre-wired for 230V or

460V per customer request. If it becomes necessary to

change the voltage, remove the back cover from the base

and place the machine on its side. Remove the terminal

cover from the motor. Rewire the motor according to the

motor connection diagram, Figure 32 or, Figure 33). This

completes the voltage conversion process

Circuit Protection

Where the service branch is protected with a fuse or

circuit breaker that has too high a value to offer protection to

the motor supplied, a fuse or circuit breaker box should be

used at the point where the machine connection is made

and the time delay fuse or circuit breaker should be a value

just slightly higher than the maximum load current draw.