9

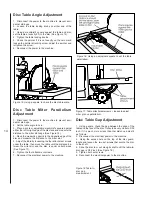

Figure 2: Lock bolts for belt arm

Figure 3: Arm at horizontal -- note that the table is removed.

The table may be removed or left in position, and may also

be set to any angle to allow horizontal sanding of various

angles.

CAUTION:

NEVER ADJUST THE ARM ANGLE

WHILE THE SANDER IS RUNNING. ALWAYS TURN

OFF THE MOTOR BEFORE ADJUSTING THE ARM

ANGLE.

Figure 4: Disc sander table adjustment

Adjusting the Disc Sander Table

1. Unlock the two locking knobs underneath the table at

each end. (See Figure 4.)

2. Using the pointer and scale, set the angle to any re-

quired angle between 20

o

upward and 45

o

downward.

3. Lock the two locking knobs underneath the table.

CAUTION:

NEVER ADJUST THE TABLE ANGLE

WHILE THE SANDER IS RUNNING. ALWAYS TURN

THE MOTOR OFF BEFORE ADJUSTING THE TABLE

ANGLE.

Figure 5: Use of the miter system

Use of the Miter Gauge

The miter gauge can be used on either the disc or

belt surfaces to sand accurate angles on workpieces. When

using the gauge, alone, you sand a single angle. However,

by tilting the table and using the miter gauge in combina-

tion with the table tilt, it is possible to sand compound

angles, as well.

When grinding a compound angle you should al-

ways check the accuracy of your setup by sanding a piece

of scrap material before doing any finish sanding on the

actual workpiece.

1. Set the angle you wish to sand using the scale on the

miter gauge.

2. Tighten the miter gauge securely so the miter reference

surface will not move while you are sanding.

3. Place the workpiece against the miter reference surface

and slide it along the reference surface and into the sand-

ing disc or belt. The basic method is shown in Figure 5,

below.