3180-10

10

60706-238

4 Turn the off/on engine switch to the on position.

5. Pull the starter grip lightly until resistance is felt,

then pull briskly.

6. When the engine starts, open the choke

gradually.

7. The engine should promptly come up to

operating

speed.

NOTICE:

Do not allow the starter grip to snap back against

the engine. Return it gently to prevent damage to the

starter.

ELECTRIC STARTING (Gasoline only)

If the engine is cold and stiff or if the battery is not

fully charged, starting can be made easier by slowly

hand cranking the engine through the compression

stroke before pushing the starter switch. This permits

the starter to gain momentum before the heavy load

of the compression stroke occurs. This minimizes

the drain on the battery and improves the possibility

of starting under such adverse conditions. Always

keep the battery charged, especially during cold

weather operation.

1. Check oil level, refi ll as needed.

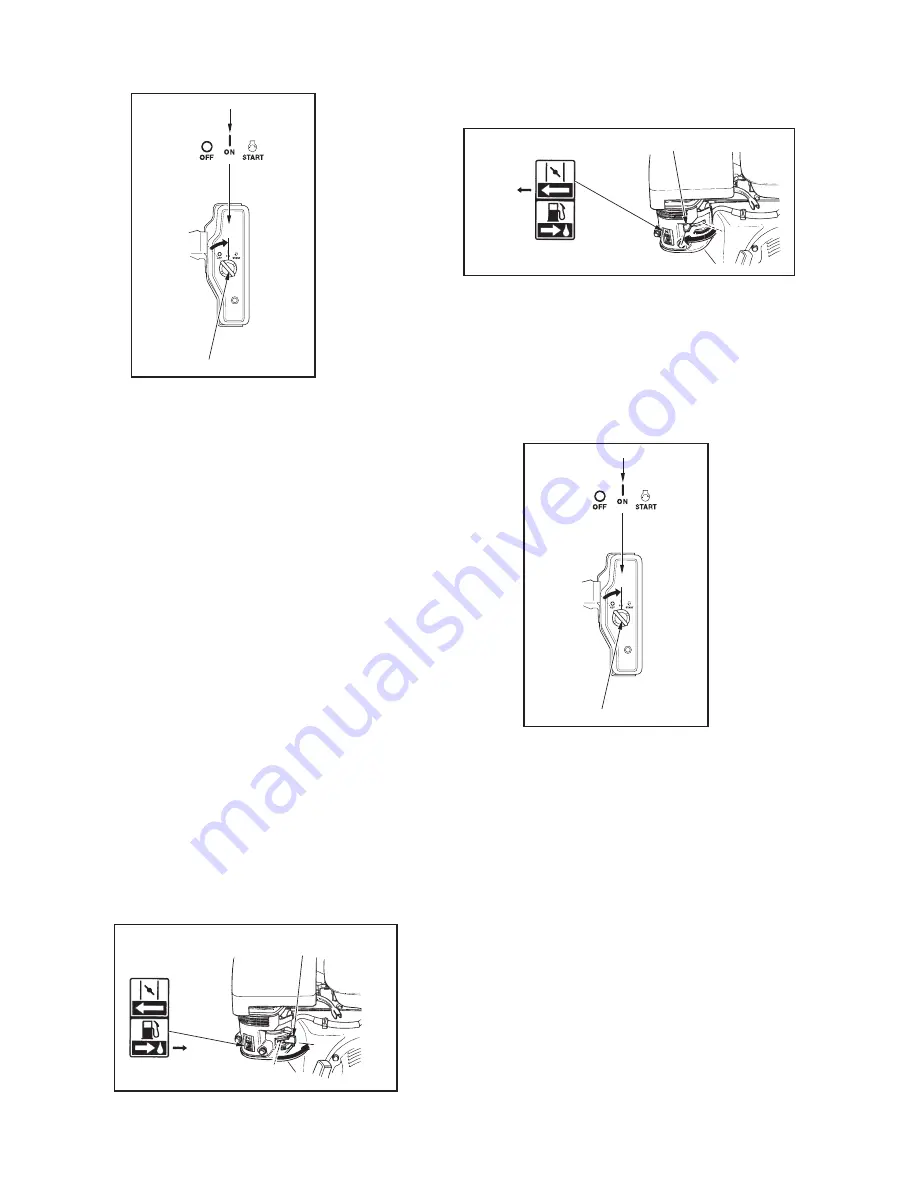

2. Turn on the fuel supply by moving the fuel lever

to the “ON” position.

3. Move the choke lever to the “CLOSED” position.

To restart a warm engine, leave the choke lever in

the “OPEN” position

4. Turn the engine switch to the “on” position

5.. Operating the starter. Rotate the engine switch

briefl y to the START position. The starter life is

improved by using shorter starting cycles with

time to cool off between cranking cycles. Do

not operate the starter more than 5 seconds and

wait at least 10 seconds before operating the

starter again, Repeat cycle if necessary.

6. When the engine starts, release the engine

switch, allowing it to return to the “on” position.

7. Gradually move choke to the open position as

the engine warms up..

6. The engine should promptly come up to

operating

speed.

CAUTION: EQUIPMENT DAMAGE

Never permit the choke to remain on after the

engine has run for a short time. It is not necessary to

choke the engine when it is warm. Avoid over-chok-

ing.

ON

MAX.

ON

MIN.

OPEN

OPEN

ENGINE SWITCH

ON

CLOSED

ON

MIN.

OFF

O

O

N

N

MAX.

MIN.

OPEN

OPEN

FUEL VALVE LEVER

O

O

N

N

CLOSED

MIN.

ON

MAX.

MIN.

OPEN

CLOSED

O

O

P

P

E

E

N

N

ON

C

C

L

L

O

O

S

S

E

E

D

D

CHOKE LEVER

MIN.

ON

MAX.

ON

MIN.

OPEN

OPEN

ENGINE SWITCH

ON

CLOSED

ON

MIN.