3180-10

8

60706-238

CHANGING FUEL TYPES

These engine generator sets are designed to run on

two different fuels; gasoline, and natural gas. They

may be easily changed from one fuel to another.

FROM GASOLINE TO NG

1. With the engine running turn off the gasoline

fuel valve.

2. Run the engine until it runs out of fuel.

3. Remove the plastic insert from the demand

regulator.

4. Install a locally approved fl exible fuel line.

5. Connect the NG vapor fuel line to the fl exible

fuel line. You can’t connect the black iron pipe

directly

6. Turn on the NG fuel supply.

7. Start the engine.

8 . Apply the load to the generator.

FROM NG TO GASOLINE

1. With the engine running turn off the NG fuel

supply.

2. Run the engine until it runs out of fuel.

3. Remove

the

fl exible fuel line from the demand

regulator.

4. Reinstall the plastic insert in the regulator.

5. Check to be sure the gasoline fuel valve is

off.

6. Fill the gasoline fuel tank.

7. Turn on the gasoline fuel valve.

8. Start the engine.

If the optional FUEL SOLENOID kit has been in

stalled on the unit all vapor fuel connection will be

made at the 12 volt gas valve

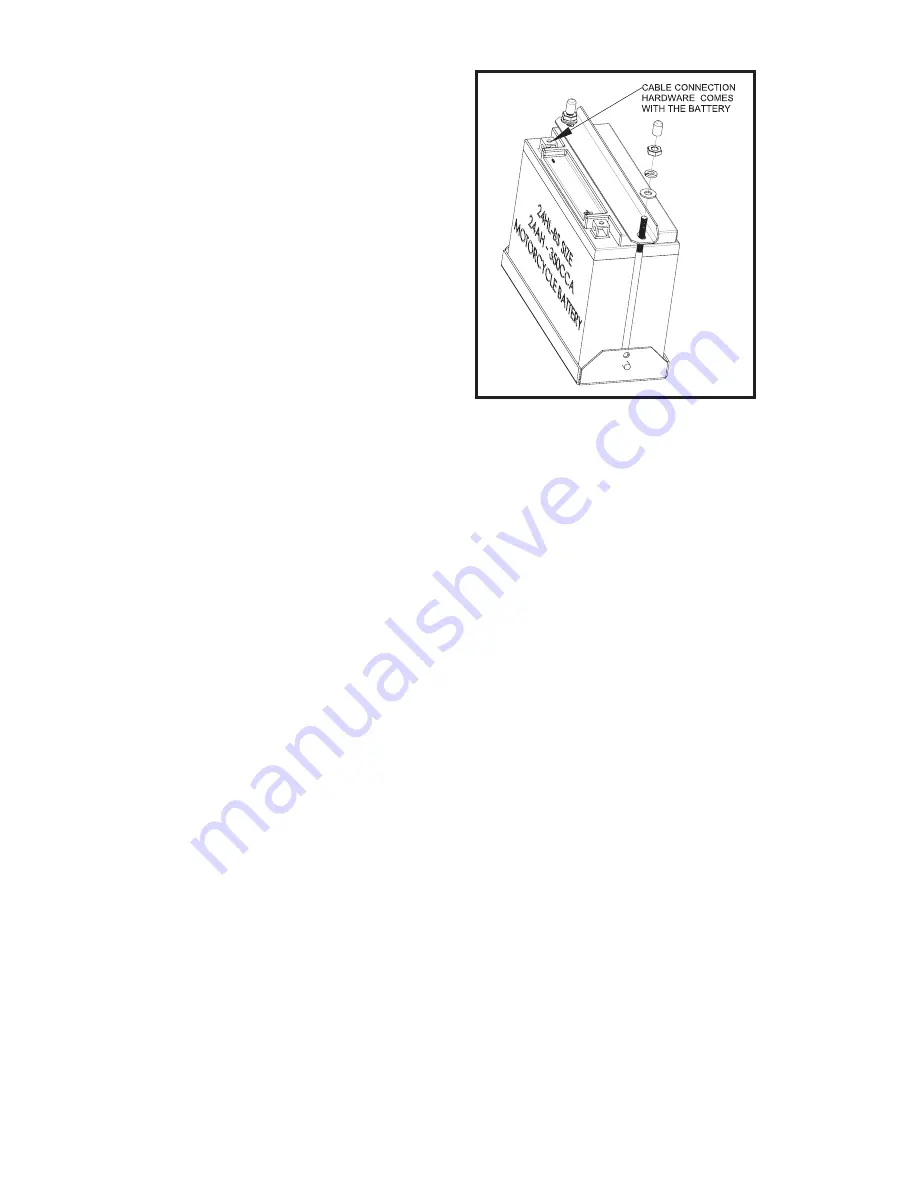

BATTERY INSTALLATION

The HPS6000HE generator set is shipped with a

battery tie down kit for customer installation. This kit

consists of a battery tie down and hardware for instal-

lation of the customer supplied battery on the unit.

If you intend to use the power plant’s electric start

system, (required when using NG) you will need to

purchase and install a battery to operate it. Units

equipped with a recoil or rope start will operate satis-

factorily without a battery on gasoline.

WARNING: EQUIPMENT DAMAGE

The battery positive (+) cable is shipped with a

plastic protective cap. When starting manually, this

protective cap must remain in place to avoid pos-

sible damage to the engine electrical system and/or

generator end.

A 12-volt powersports (motorcycle/atv/snowmo-

bile) battery,

BCI group 20 or 24HL rated at 300

CCA

or larger is recommended for this electric start

engine generator set. Maximum length: 8 1/8”, Maxi-

mum width: 3 9/16”, Height range: 5 3/4” - 7”. Amp

Hours: 15AH or greater. Follow the battery manufac-

turers recommendations for servicing and charging

prior to use. Connect the battery to the electric start

system using the cables provided..

CAUTION: EQUIPMENT DAMAGE

These electric start engines are NEGATIVE

GROUND. Use extreme caution when connecting the

battery. Connect the NEGATIVE battery terminal to

GROUND.

For your safety always connect the positive battery

cable to the “bat+” terminal fi rst. Then connect the

negative battery cable to the “bat-” terminal. Make

sure all connections are clean and tight. Reverse the

sequence when disconnecting, disconnect the nega-

tive cable fi rst. These engines produce enough direct

current to keep a battery charged under normal oper-

ating conditions, but were not intended to be used as

a battery charger.