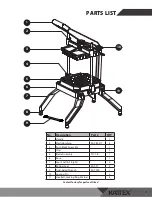

4

PREPARATION

1. Using the wrench provided, remove the hex bolt, lock washer,

and washer from the base. Using the wrench provided,

attach the leg to the base with the hex bolt, lock washer, and

washer. Repeat process for the remaining legs.

2. Attach the handle the the push block assembly and link bars

with the locking pins.

Note: Configuration 1 is for in use and Configuration 2 is for

locking the handle and push assembly in up position.

Config. 1 - in use

Config. 2 - locked

Note: There are left and right legs.