6

CLEANING

Note: Hand washing unit is recommended as washing in a

commercial dishwasher will cause the all aluminum parts

to darken over time, this is normal, and does not effect the

general operation of the unit.

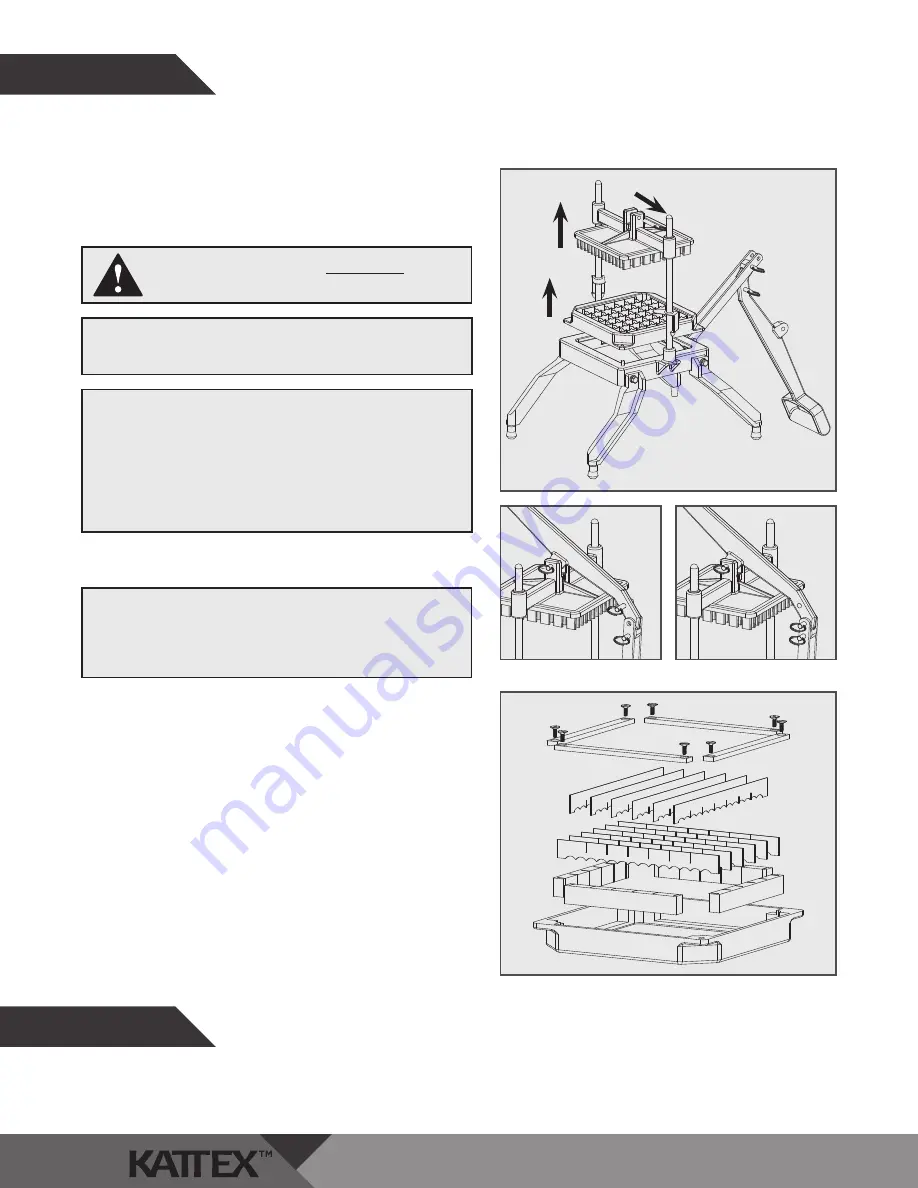

1. Remove the pin on the push block assembly, move the handle

out of the way, and lift the push assembly off the guide rods.

2. Remove the blade assemby off the pins on the base.

3. Thoroughly wash/rinse/sanitize parts in warms soapy water,

dry and carefully reassemble.

Cleaning of the device is important to assuring optimal performance and longevity.

Minimize the use of alkaline or acidic cleaners, as they may cause pitting and dulling of the finish.

WARNING: THE BLADES ARE

VERY SHARP

.

PLEASE USE CAUTION WHEN HANDLING

MAINTENANCE

As needed, lubricate the guide rods with mineral oil, food grade grease, or rub them with Paraffin.

Do not lubricate with cooking oil.

Config. 1 - in use

Config. 2 - locked

Note: The blades in the blade block assembly can also be

dissembled for blade replacements or additional cleaning

as required.

a. Remove screws and the blade holder covers.

b. Gently lift blades and the blade spacers from the

blade holder.

Note: The blade assembly can also be removed when the

push block assembly is locked in the up position.