16

60706-229/G

INITIAL START UP

WARNING

DO NOT jump start these engine generator sets. Starting

these units on a low battery of jump starting them will

cause damage to the engine control module.

Use the following checklist to verify correct installation

before starting the engine:

□

Engine oil.* Check level & fill as required with proper

grade/quantity.

□

Unit mounting base properly bolted down.

□

Clearance for service and maintenance on all sides.

□

Proper fuel line material and size.

□

All fuel line connections tight.

□

Fuel line protected and a moisture trap installed

(may be required for NG).

□

LP/NG pressure OK. 4-6 oz. (7-11 in. WC).

□

Battery connections clean and tight.

□

Battery fully charged.

□

All AC and DC wiring installed and properly

protected.

*Refer to engine owners manual for proper levels and

types. After completing the above checklist, the engine

generator set is ready for the initial start-up test.

START UP PROCEDURE

ENGINE-GENERATOR SET ONLY

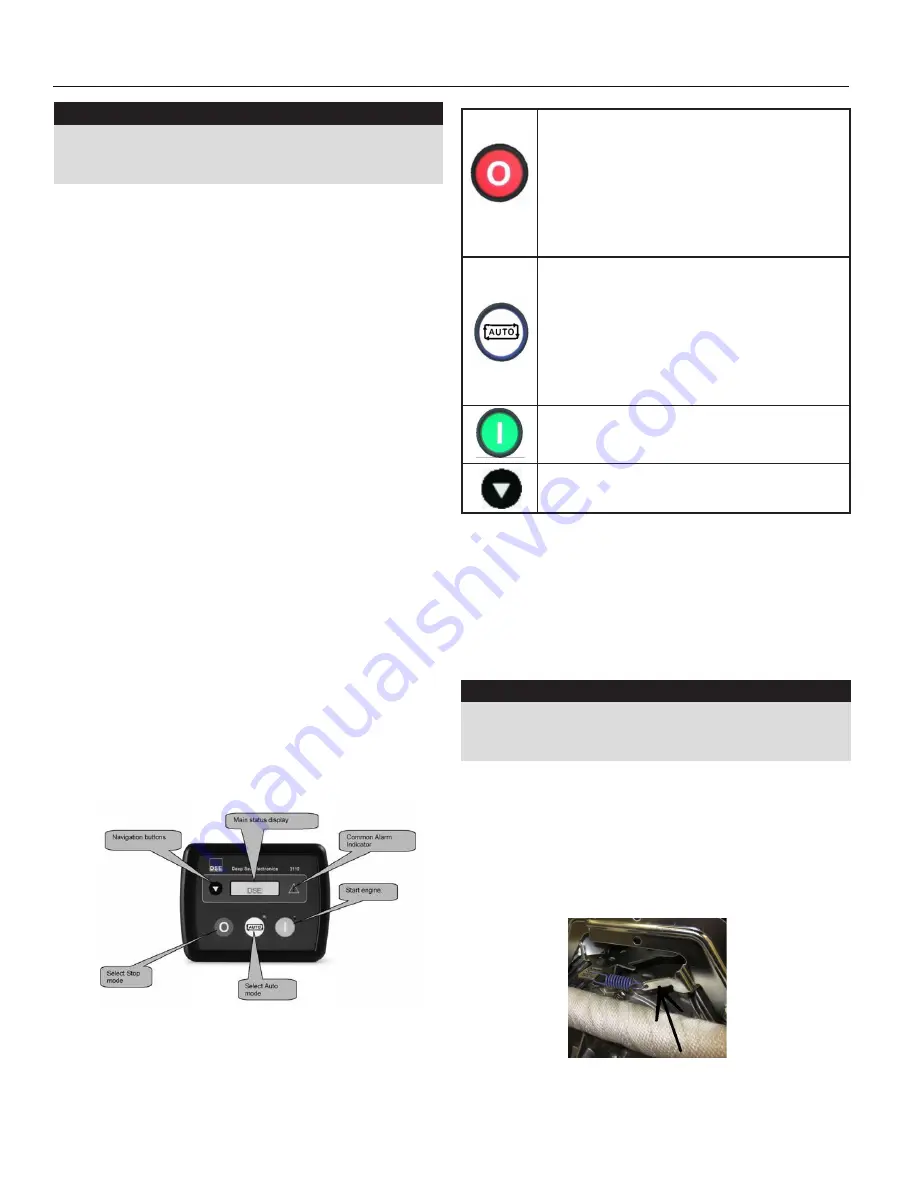

The engine control module (ECM) is manufactured by Deep

Sea Electronics. Model 3110 is used on this generator set.

See following picture and look for more information stated

within this manual.

MANUAL OPERATION

Press and release the red Stop/Reset button. Then press

and release the green Start Engine button. The engine-

generator will crank and start automatically. If the engine

fails to start, reference the fault codes to correct the problem

before proceeding.

10

REV B

60706-229

DC ELECTRICAL INTERCONNECTION

CAUTION:

Never run the AC and DC wiring on the same conduit.

ASCO 185 UL SWITCH

Your DC connection points in the ASCO 185 UL ATS are on the

terminal block on the bottom of the controller in the lower left hand

corner of the ATS panel. The terminal block (TB7) is numbered 1

through 9. These terminals will accept # 22 - # 14 AWG stranded wire.

It is recommended that you use # 16 AWG for distances up to 200

feet. You need to run two (2) wires from the engine generator set to the

transfer switch. You will be using terminals 4 and 5, wire Start # 23 will

connect to terminal # 5 and wire Battery Negative # 1 will connect to

terminal # 4. See the following table and illustration.

Wire #

Purpose

Recommended Color

#23

Start

Black

#1

Battery negative

White

INITIAL START UP

WARNING:

DO NOT jump start these engine generator sets. Starting these units

on a low battery of jump starting them will cause damage to the engine

control module.

Use the following checklist to verify correct installation before starting

the engine:

Ƒ(QJLQHRLO&KHFNOHYHO ¿OODVUHTXLUHGZLWKSURSHU

grade/quantity.

Ƒ8QLWPRXQWLQJEDVHSURSHUO\EROWHGGRZQ

Ƒ&OHDUDQFHIRUVHUYLFHDQGPDLQWHQDQFHRQDOOVLGHV

Ƒ3URSHUIXHOOLQHPDWHULDODQGVL]H

Ƒ$OOIXHOOLQHFRQQHFWLRQVWLJKW

Ƒ)XHOOLQHSURWHFWHGDQGDPRLVWXUHWUDSLQVWDOOHGPD\EH

required for NG).

Ƒ/31*SUHVVXUH2.R]LQ:&

Ƒ%DWWHU\FRQQHFWLRQVFOHDQDQGWLJKW

Ƒ%DWWHU\IXOO\FKDUJHG

Ƒ$OO$&DQG'&ZLULQJLQVWDOOHGDQGSURSHUO\SURWHFWHG

* Refer to engine owners manual for proper levels and types.

After completing the above checklist, the engine generator set is ready

for the initial start-up test.

START UP PROCEDURE

ENGINE-GENERATOR SET ONLY

The engine control module (ECM) is manufactured by Deep Sea

Electronics. Model 3110 is used on this generator set.

See following picture and look for more information stated within this

manual.

MANUAL OPERATION

Press and release the red Stop/Reset button. Then press and release

the green Start Engine button. The engine-generator will crank and

start automatically. If the engine fails to start, reference the fault codes

to correct the problem before proceeding.

generator under load. Should you ever have to work on the switch,

you will be able to disconnect the power and work on the switch cold

without having the power company pull your meter.

7RZLUHWKHDXWRPDWLFWUDQVIHUVZLWFKLQWRWKHH[LVWLQJZLULQJ¿UVW

determine which circuits will be on the emergency load circuit. If the

entire load is to be transferred, the transfer switch can be wired in

directly after the watt-hour meter and the service entrance, providing

WKHVHUYLFHHQWUDQFHDPSHUHUDWLQJLVZLWKLQWKHWUDQVIHUVZLWFK¶VUDWHG

capability.

,IRQO\VSHFL¿FFLUFXLWVDUHWREHSRZHUHGXQGHUHPHUJHQF\SRZHU

failure conditions, an additional distribution panel designated

“emergency distribution panel” must be installed.

All selected emergency circuits are removed from main distribution

panels and reinstalled in the emergency distribution panel. Suggested

circuits: freezer, refrigerator, furnace, emergency lights, sump pump,

emergency outlet circuits, etc. Total running load must not exceed

generator rating.

STOP/RESET (red button) - This button places

the module into its Stop/Reset mode. This

will clear any alarm conditions for which the

triggering criteria have been removed. The

fuel supply de-energizes and the engine comes

to a standstill. Should a remote start signal be

present while operating in this mode, a remote

start WILL NOT occur.

AUTO (white button) - This button places the

module into its Automatic mode. This mode

allows the module to control the function of

the generator automatically. The module will

monitor the remote start input and once a start

request is made, the set will be automatically

started and placed on load. The module will

then wait until the next start event.

START (green button) - Pressing this button

from STOP/RESET will start the engine and run

the load.

PAGE - Pressing this button scrolls the display to

show the various instruments.

With the engine running soothly, check the no load voltage

and frequency wire #1 and #4 on the generator terminal

block in the ATS (L2 and L6 in the ASCO ATS). The voltage

should be 240 Volts plus or minus nominal. The frequency

should be between 61.5 to 62 Hertz (Hz). The Voltage

should also be checked between the hot terminals (L2 and

L6) and the neutral connection. The Voltage should be

about one half of the line to line Voltage. See the following

picture to frequency adjustments.

NOTICE

If for any reason during the check out procedures the

Voltage and frequency are not correct, press the red Stop/

Reset button and correct the trouble before proceeding.

After verifying the Voltage and frequency are correct,

press the Stop/Reset button. This will shut off the engine

immediately.

Bend this tab to change the engine speed (frequency).

Stretching the spring increases the frequency (increases

engine speed). Relaxing spring decreases the frequency

(decreases engine speed). Different units will vary.

Summary of Contents for PSS20B2W/A

Page 19: ...19 60706 229 G...

Page 24: ...24 60706 229 G OUTLINE DRAWING...

Page 25: ...25 60706 229 G PAD LAYOUT 60706 229 23 12270 01 60706 229 ET A ENGINE GENERATOR SET PAD LAYOUT...

Page 26: ...26 60706 229 G AC AND DC GENERATOR SCHEMATIC...

Page 27: ...27 60706 229 G AC WIRING SCHEMATIC PSS20 3 A PSS20 17 A PSS20 18 A PSS20 4 A...