17

60706-229/G

TRANSFER SWITCH & ENGINE-GENERATOR

Automatic (remote) Operation

This procedure checks the electrical operation of the

automatic transfer switch. If the actual operation does not

follow procedure, consult the trouble-shooting section in

the transfer switch manual.

1. Turn on the preferred source (utility) circuit breaker.

The Utility Acceptable Light should now come on, as

well as the Load on Utility Light. If those lights fail to

come on, recheck your incoming power to ensure you

have 240 Volts nominal. If not, troubleshoot your utility

source before continuing.

2. Press and release the Auto button on the engine

control module (ECM). The auto mode icon will appear

on the screen. The unit is now ready to be operated

from the Automatic Transfer Switch.

3. Turn on the alternate source (generator) circuit

breaker.

WARNING: PERSONAL INJURY HAZARD

Install front cover in transfer switch before operation.

An electrical system fault could cause a flash and severe

personal injury.

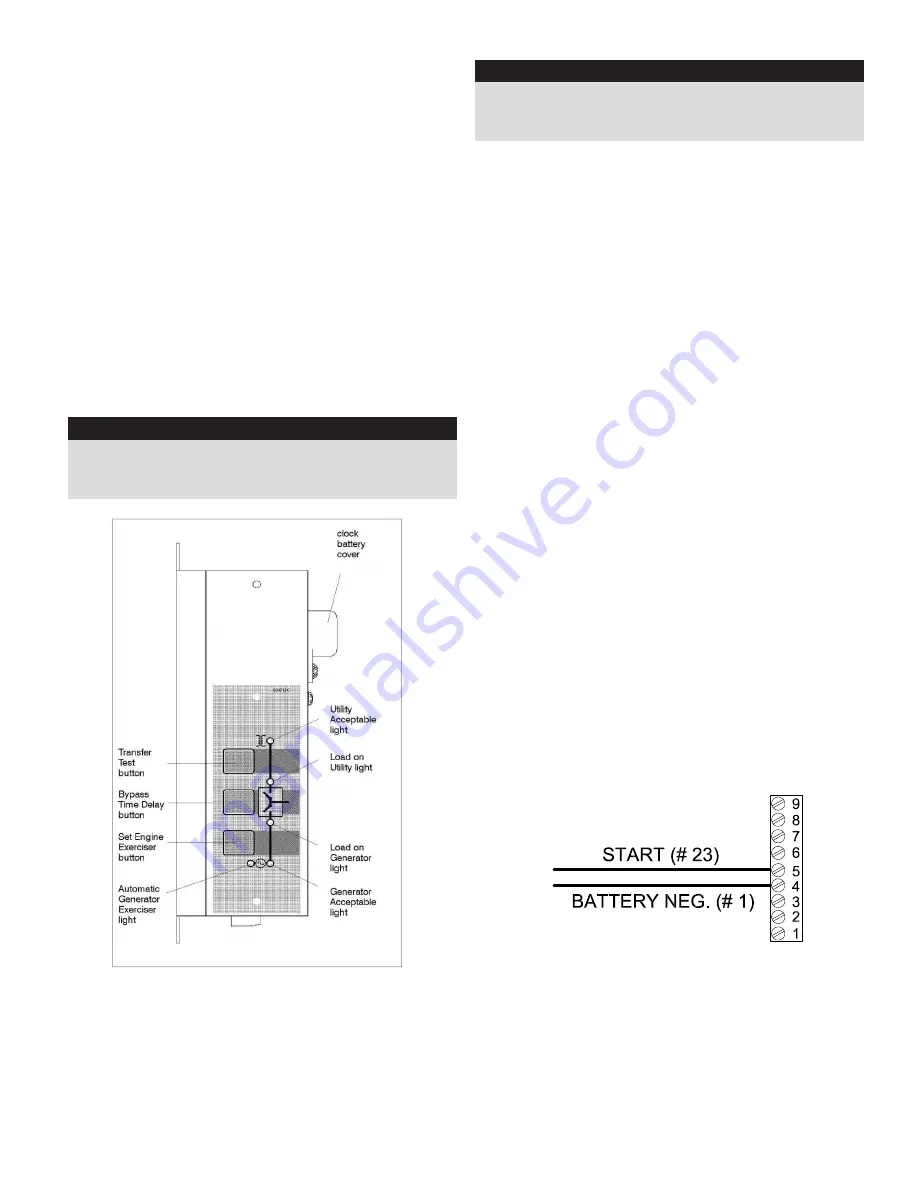

The digital controller provides sensing, timing, and control

functions for the ATS. This micro-processor-based controller

includes built-in control buttons and status lights for control

of the ATS and the generator.

PUSH BUTTONS

On the front control display are the three push buttons that

control the operation of the generator and the ATS.

CAUTION

Before using the transfer test button, be sure that

conditions are safe for running the generator and for load

tester.

TRANSFER TEST

Use this button to test the system. This operation starts

the generator and transfers the load. The controller is

shipped with a load transfer set by default. Changing the

exercise without a load will be discussed later. Be sure that

conditions are safe to do this operation.

BYPASS TIME DELAY

Use this button to cancel the active time delay or exercise

period (stops the generator after cool-down).

SET ENGINE EXERCISER

Use this button to set the automatic exerciser.

INDICATOR LIGHTS

On the front control display are five lights that indicate the

status of the sources and the ATS.

UTILITY ACCEPTABLE

This light indicates that tehe utility voltage is acceptable for

connection to the loads.

GENERATOR ACCEPTABLE

This light indicates that the generator voltage and

frequency is acceptable for connection to the load.

LOAD ON UTILITY

This light indicates that the generator voltage is acceptable

for connection to the load.

AUTOMATIC GENERATOR EXERCISER

This light indicates the status of the generator exerciser:

• Blinks during the exercise period (including cool down)

• Stays on when the exerciser has been set.

• Is off when the exerciser has not been set.

GENERATOR STARTING CONTACTS

Disconnect the generator battery. Connect the generator

starting wires #1 (battery -) to terminal 4; wire #23 (start) to

terminal 5 of the TB7 terminal block. This is removable for

convenient connections.

GENERATOR EXERCISER CIRCUIT

The automatic generator exerciser is configured to

automatically exercise the generator for 20 minutes once

every week.

In order to set and test the exercise circuit the AUTO button

on the generator control panel must be on.

EXERCISE WITH OR WITHOUT LOAD

The transfer switch can be set up to exercise the generator

Summary of Contents for PSS20B2W/A

Page 19: ...19 60706 229 G...

Page 24: ...24 60706 229 G OUTLINE DRAWING...

Page 25: ...25 60706 229 G PAD LAYOUT 60706 229 23 12270 01 60706 229 ET A ENGINE GENERATOR SET PAD LAYOUT...

Page 26: ...26 60706 229 G AC AND DC GENERATOR SCHEMATIC...

Page 27: ...27 60706 229 G AC WIRING SCHEMATIC PSS20 3 A PSS20 17 A PSS20 18 A PSS20 4 A...