20

60706-229/G

DSE 3110

FRONT PANEL CONFIGURATION

ACCEPT

DECREASE

VALUE/

BUTTON

NEXT ITEM BUTTON

NEXT PAGE

INCREASE

VALUE/

BUTTON

NEXT

ITEM

BUTTON

This configuration mode allows the operator limited

customizing of the way the module operates. Use the

module’s navigation buttons to traverse the menu and

make value changes to the parameters.

ACCESSING THE FRONT PANEL

Press

and simultaneously. This display shows the

configuration icon: The first parameter is also displayed.

EDITING A PARAMETER

1. Press to select the required ‘page’ as detailed below.

2. Press to select the next parameter or to select

the previous parameter within the current page.

3. When viewing the parameter to be changed, press .

The value begins to flash.

4. Press or to adjust the value to the requested

setting.

5. Press to save the current value. The value stops

flashing.

6. Press and hold the button to exit the editor, the is

removed from the display.

NOTE:

Values representing pressure will be displayed in Bar.

Values representing temperature are displayed in degrees

Celsius.

When adjusting values in the front panel editor, a “press

and hold” of the increment button will cover the full

range of the item being adjusted (min to max) in under 20

seconds.

When the editor is visible, it will exit after 5 minutes of

inactivity for security.

DSE 3110 FAULT CODES

Auxiliary inputs can be user configured and will

display he message as written by the user.

Fail to Start. The engine has not fired after the

preset number of start attempts.

Fail to Stop. The module has detected a condition

that indicates that the engine is running when it

has been instructed to stop.

NOTE:- ‘Fail to Stop’ could indicate a faulty oil

pressure sensor - If engine is at rest, check oil

sensor wiring and configuration.

Low Oil Pressure. The module detects that the

engine oil pressure has fallen below the low oil

pressure pre-alarm setting level after the Safety

On timer has expired.

Engine High Oil Temperature. The module

detects that the engine oil temperature has

exceeded the high engine temperature pre-alarm

setting level after the Safety On timer has expired.

Underspeed - The engine speed has fallen below

the underspeed pre-alarm setting.

Overspeed - The engine speed has risen above

the overspeed pre-alarm setting.

Battery Under/Over Voltage. The DC supply has

fallen bleow or risen above the low/high Volts

setting level.

Generator Under Voltage - The generator output

voltage has fallen below the pre-set pre-alarm

setting level.

Generator Over Voltage - The generator output

voltage has risen above the pre-set pre-alarm

setting after the Safety On timer has expired.

Generator Under Frequency - The generator

frequency has fallen below the pre-set pre-alarm

setting after the Safety On timer has expired.

Generator Over Frequency - The generator

output frequency has risen above the pre-set pre-

alarm setting

Summary of Contents for PSS20B2W/A

Page 19: ...19 60706 229 G...

Page 24: ...24 60706 229 G OUTLINE DRAWING...

Page 25: ...25 60706 229 G PAD LAYOUT 60706 229 23 12270 01 60706 229 ET A ENGINE GENERATOR SET PAD LAYOUT...

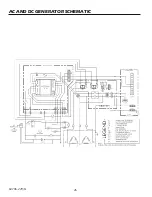

Page 26: ...26 60706 229 G AC AND DC GENERATOR SCHEMATIC...

Page 27: ...27 60706 229 G AC WIRING SCHEMATIC PSS20 3 A PSS20 17 A PSS20 18 A PSS20 4 A...