8

60706-229/G

INSTALLATION

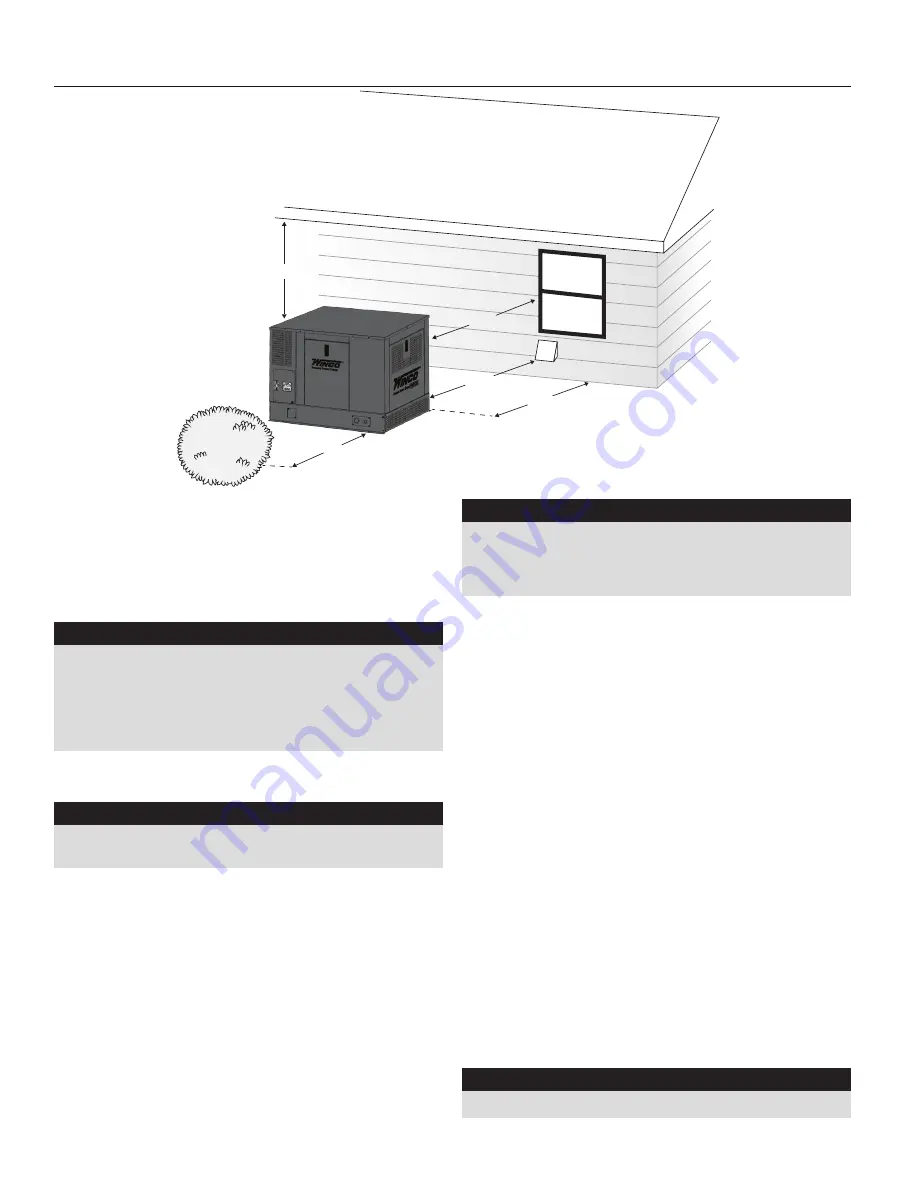

GENERATOR CLEARANCES

These units should be mounted a minimum of 24” from

a structure. This will allow for ample room to maintain

and work on the generator set. Units must be installed in

accordance with all local, state, and national codes. Consult

your local agency for specific requirements.

DANGER: DEADLY EXHAUST GAS

Carbon monoxide (CO) is an orderless, deadly gas. Keep

genset exhaust a minimum of 60 inches away from vents,

windows, doors, soffit, and other openings to the building.

Check with local codes for more information about

generator clearances. Failure to safely install your genset

can result in serious personal injury and/or death.

ENGINE-GENERATOR SET MOUNTING

WARNING

Before proceeding with installation, be sure the operation

selector switch is in the stop position.

These engine generator sets are designed to be mounted

on a pad outdoors only. The transfer switch is mounted

next to your electrical entrance or distribution panel

inside or outside the building. Consult a qualified, licensed

electrician or contractor to install and wire the transfer

switch. The installation must comply with all national, state

and local codes. Before beginning the installation process

check the rating of the generator set and its transfer

switch rating. Be certain they can handle the intended

load and are compatible with the entrance voltage,

phase and current ratings. Plans for installation should

be prepared with proper attention to mechanical and

electrical engineering detail to assure a satisfactory system

installation. The information in this manual is offered only as

a guide to finalizing your installation plans.

WARNING: PERSONAL INJURY

The enclosures on these units can become very hot

adjacent to the exhaust areas. Special care must be taken

when installing these units to insure that the risk of contact

by people is minimized.

The unit’s main frame should be bolted to a pad that meets

local code. Various materials, including concrete and

composites, are acceptable as long as they are structurally

sound supporting the weight of the unit and preventing

movement during operation. The mounting holes on the

base of this unit is 0.563” in diameter. The engine-generator

is mounted on a sub-frame which is isolated with special

shock mounts on the main frame. This allows the engine-

generator to vibrate without affecting the control panel on

the main frame.

Do not install any shock mounts between the base frame

and the pad. Engine vibration will be transmitted to the

control panel causing erroneous start/stop cycles and

premature control failure.

FUEL INSTALLATION

The fuel supply should be as close as possible to the

engine. This will reduce the installation cost of fuel runs.

The information in this manual is offered to assist you in

providing the proper fuel for your engine. However, this

information is only provided to inform you of the engine’s

requirements and assist in making you aware of the

decisions you must make. In no case should the instructions

and information provided be interpreted to conflict with

any local, state or national codes. If in doubt, always consult

your local fire marshal, gas supplier or building inspector.

WARNING: FIRE HAZARD

All fuel runs should be installed by a licensed fuel supplier.

60” Minimum

60” Minimum

60” Minimum

24” Minimum

24” Minimum

Summary of Contents for PSS20B2W/A

Page 19: ...19 60706 229 G...

Page 24: ...24 60706 229 G OUTLINE DRAWING...

Page 25: ...25 60706 229 G PAD LAYOUT 60706 229 23 12270 01 60706 229 ET A ENGINE GENERATOR SET PAD LAYOUT...

Page 26: ...26 60706 229 G AC AND DC GENERATOR SCHEMATIC...

Page 27: ...27 60706 229 G AC WIRING SCHEMATIC PSS20 3 A PSS20 17 A PSS20 18 A PSS20 4 A...