15

OPM-117/D

CAUTION

Never run the AC and DC wiring on the same conduit.

NOTE: There are various DC connectors on the engine

that have nothing connected to them. This was done

intentionally, the connectors are for END OF THE LINE

TESTING and other diagnostic tests. They are not used

during normal operations and can just be ignored.

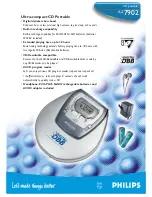

All DC connections are completed on the terminal strip just

below the engine control cabinet.

A - Customer Remote Start CONNECTIONS TERMINALS.

The two remote start leads from the Automatic Transfer

Switch are connected to the two terminals marked 1 & 23.

The wire in terminal labeled #1 is Battery Negative/Ground

and the wire in the terminal labeled #23 is your Remote

Start lead. Closing these two leads together will signal the

DSE 7310 MKII to go into an autostart mode and start up

the engine generator. Depending on the distance, 14 to 16

gauge stranded wire should be used. It is suggested that

these wires be labeled S1 and S23.

Note: Any relay closure can be used to start and stop this

generator. As long as the contact stays closed the engine

generator set will continue to run. Once the relay is opened

the unit will shut down and remain in the standby mode

until the remote start relay is closed again.

B - ESTOP- & ESTOP+. Remote Emergency Stop terminals.

These two terminals are shipped with a jumper installed.

If your application requires the installation of a Remote

Emergency Stop switch, remove the jumper and wire your

switch to these terminals. This unit will not start and run

without either the jumper installed or a remote N/C switch

installed..

C - Battery Charger Failure. Battery charger failure relay

input from remote battery charger to DSE7310 MKII

controller.

D - Remote Display Panel Interface Terminals. These

interface terminals are pre-wired to allow for the connection

of a remote display. This display allows for the remote

annunciation of alarms at a location such as a nurses station

or a control room.

E - Battery Positive and Ground ( battery negative). These

terminals are dedicated for any accessory that will be

installed. There is a maximum of 7 Amps combined.

D

C

B

A

E

DC INTERCONNECTIONS TO ATS

Two control wires are required between the ATS panel

and the generator control terminal box. Depending on the

distance, 14 and 16 gauge stranded wire should be used.

These wires should be labeled S1 and S23.

WARNING:

Be sure engine generator is in the OFF position before you

make any DC interconnections.

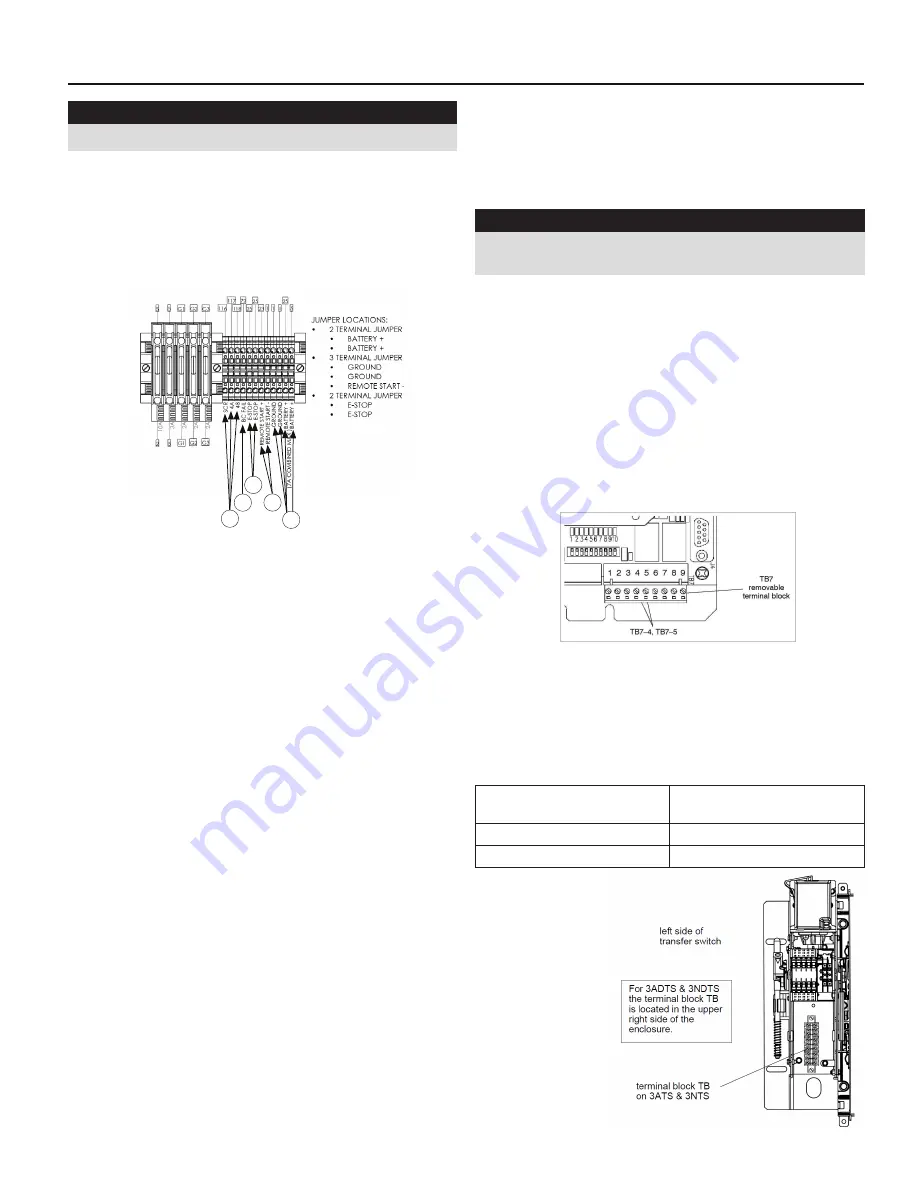

ASCO 185 UL SWITCH

Your DC connection points in the ASCO 185 UL ATS are on

the terminal block on the bottom of the controller in the

lower left hand corner of the ATS panel. The terminal block

(TB7) is numbered 1 through 9. These terminals will accept

# 22 - # 14 AWG stranded wire. It is recommended that you

use # 16 AWG for distances up to 200 feet. You need to run

two (2) wires from the engine generator set to the transfer

switch. You will be using terminals 4 and 5, wire Start # 23

will connect to terminal # 5 and wire Battery Negative #

1 will connect to terminal # 4. See the following table and

illustration.

Your DC connection points in the ASCO 185 ATS are

terminals “4” and “5” on the interface terminal block. As this

is a “DRY” unpowered contract set it set, it makes difference

which lead (battery negative #1 or start #23) connect to

which terminal.

ASCO 300 UL SWITCH

When Normal

Source Fails

Terminals On

Transfer Switch

Contact Closes

TB1 and TB2

Contact Opens

TB1 and TB3

Engine start and

auxiliary circuit

terminal block TB

located on 3ATS

&3NTS transfer

switch.

DC ELECTRICAL INTERCONNECTION