19

OPM-160/A

Reasonable care in preventative maintenance will ensure

high reliability and a long life for the engine-generator set

and Automatic Transfer Switch.

WARNING:

When performing any type of maintenance on this

equipment, make sure the selector switch on the engine-

generator is in the off position. If you are working in the

Automatic Transfer Switch, confirm with a reliable meter

that all power has been disconnected.

AUTOMATIC TRANSFER SWITCH

Clean and inspect the switch once a year. De-energize

all power sources, both line and engine-generator set,

then brush and vacuum away any excessive dust or

dirt accumulation. At this time, with the conductor de-

energized, you can remove the contact covers and check

the contacts. Make sure contacts are clean and not burned

or pitted.

ENGINE-GENERATOR SET

Service the engine in accordance with the engine

manufacturer’s manual provided with your new equipment.

Routinely remove debris and dirt from around the inside

generator enclosure. Ensure that the air intakes are free

from leaves and other debris at all times.

Clean and inspect battery terminals at least twice a year.

Also check the battery water level at least twice a year.

Other than keeping the generator clean and free of debris,

there is no other routine or preventative maintenance

required as long as the generator is run bi-weekly to keep it

dry and in good working order.

COLD WEATHER OPERATION

Extreme cold weather operation requires special

considerations. Higher CCA batteries are required for cold

weather starting; 650 CCA or larger are recommended. In

addition, you should consider installing an oil heater kit and

a battery warmer for reliable starting during cold weather.

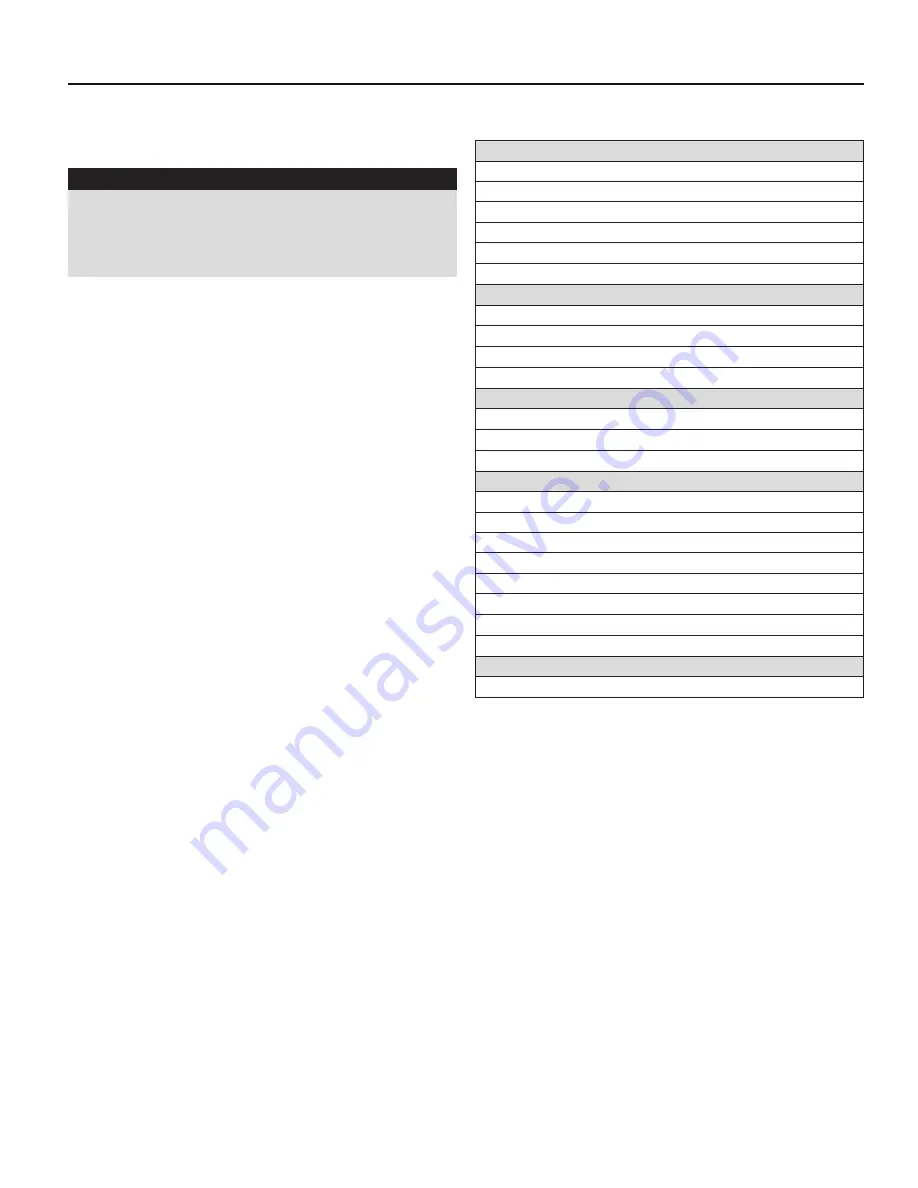

PREVENTATIVE MAINTENANCE

MAINTENANCE SCHEDULE

DAILY

Check Engine Oil Level/Replenish if Needed

Check Coolant Level/Replenish if Needed

Check for Fluid Leaks & Tightness of Clamps/hoses

Check for Loose Electrical Connections

Check Battery Connections for Corrosion

Check LPG System for Leaks

EVERY 50 HOURS OF OPERATION

Check Coolant Level/Replenish if Needed

Check for Fluid Leaks & Tightness of Clamps/hoses

Check for Loose Electrical Connections

Check LPG Tank Supply Level

EVERY 200 HOURS OF OPERATION

Check Fuel Filter Element/Replace as Necessary

Clean Debris From Radiator Core

Inspect Drive Belt for Cracks, Breaks, Splits, Glazing

EVERY 400 HOURS OF OPERATION

Change Engine Oil and Filter

Inspect Breather Hose

Check Spark Plugs

Change Air Filter

Check Air-Induction for Leaks

Inspect PCV Valve

Check All Nuts & Bolts For Tightness

Change Engine Coolant

EVERY 3000 HOURS OF OPERATION

Replace Spark Plugs

* There are additional maintenance items and explanations in the engine

operator’s manual. Read thoroughly before operating this unit.