MACHINE TROUBLESHOOTING

86373120 FLOOR POLISHER

4-2

PROBLEM CAUSE

SOLUTION

Machine will not run

Circuit breaker tripped in

building.

Check and reset.

Power switch failure

Test switch for continuity and

replace if necessary.

Tripped circuit breaker

Reset.

Faulty power cord

Replace.

Fuse in motor blown

(Dual speed only)

Replace

CAUTION: To reduce the risk

of electrical shock, unplug the

machine before opening fuse

holder. Fuse will only open

under extreme conditions.

Investigate cause before

replacing.

Electrical shock

Equipment not grounded

Follow grounding instructions

exactly.

Receptacle not grounded

Have an electrician inspects

building’s wiring.

Internal wiring problem

Ensure that the machine wiring

matches the appropriate wiring

diagram. Replace any wires or

components that are short

circuiting.

Repeated circuit breaker

tripping

Mechanical problem

Higher amp draws indicate a

mechanical problem. Find the

problem before using the

machine.

Faulty circuit breaker

Test circuit for continuity.

Replace circuit breaker if

necessary.

Excessive vibration

Pad not centered

Re-center pad.

Damaged or unevenly worn

pad

Replace pad. Do not rest

machine on pad when not in

use.

Damaged pad driver

Replace.

Pad does not turn but motor is

running

Sheer coupling has failed

Replace coupling.

Summary of Contents for 1.009-082.0

Page 16: ...NOTES 86373120 FLOOR POLISHER 3 5 ...

Page 19: ...NOTES 86373120 FLOOR POLISHER 4 3 ...

Page 20: ...BRUSH PAD DRIVER 86373120 FLOOR POLISHER 5 1 2A 2K 1 1A 1C 3 3 ...

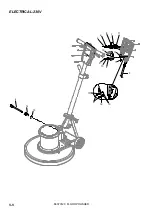

Page 22: ...ELECTRICAL 120V 86373120 FLOOR POLISHER 5 3 1 2 6 7 8 9 10 11 5 14 3 13 12 4 10 5 15 16 ...

Page 24: ...ELECTRICAL 230V 86373120 FLOOR POLISHER 5 5 13 12 4 15 10 5 16 17 1 2 6 7 8 9 10 11 5 14 3 ...

Page 26: ...DECK 86373120 FLOOR POLISHER 5 7 1 2A 2B 3 4 5 6 7 8 10 11 13 14 12 9A 9D ...

Page 30: ...MOTOR 86373120 FLOOR POLISHER 5 11 10 7 8 9 DUAL SPEED ONLY 2 3 1 5 4 6 11 15 14 13 12 ...