MACHINE OPERATION

SGJ32 86037680 01/03/07

3-14

!

WARNING

PRE-RUN MACHINE INSPECTION

1.

Do a pre-run inspection to find possible

problems that could cause poor performance or

lost time from breakdown. Follow the same

procedure each time to avoid missing steps.

Visually check for exterior damage, leaks,

damaged or worn tires.

2.

Check brushes or pads and drivers for proper

installation and wear. Weekly check scrub deck

skirts for proper contact with floor. See

BRUSHES in MAINTENANCE SECTION.

3.

Check squeegee for wear and proper

adjustment. See SQUEEGEE ADJUSTMENT in

MAINTENANCE SECTION.

4.

Check for securely attached drain hose, plug,

and caps.

5.

Check battery condition, recharge if necessary.

See BATTERIES in maintenance section.

6.

Check the brakes and steering for proper

operation. See BRAKES and STEERING in

MAINTENANCE SECTION.

STARTING MACHINE

NOTE: Perform pre-run machine check before

operating machine.

FOR SAFETY: Before starting machine, make

sure that all safety devices are in place and

operating properly.

1.

The operator should be in the seat with the right

foot on the brake pedal or with the parking brake

on. The directional pedal must be in the neutral

position to avoid unintentional movement.

NOTE: The Operator must be in position on the

seat to activate machine in desired direction.

2.

Turn the key switch clockwise to the “ON”

position.

3.

Release the brake, then press lightly on the

directional pedal in the desired direction and

drive to the filling area.

FILLING THE MACHINE

FOR SAFETY: Before leaving or servicing

machine; stop on level surface, set parking

brake, turn off machine and remove key.

1.

Set squeegee and scrub deck to up position, set

parking brake, and turn off key switch.

2.

Remove solution tank cover.

Flammable materials can

cause an explosion or fire.

Do not use flammable materials in the tanks.

3.

The solution tank can be filled to the FULL

marking of the fill inlet. Leave room for

detergent. The solution tank capacity is 30

gallons (114 liters).

The water must not be hotter than 140

'

(60

'

C) to

prevent damage to the tank. Measure the

required amount of chemical into the solution

tank after filling with water. Dry chemicals

should be thoroughly mixed before being added

into solution tank. Commercially available, high

alkaline floor cleaners are suitable for use in the

solution system.

4.

Inspect solution tank cover vent for obstructions.

Replace solution tank cover.

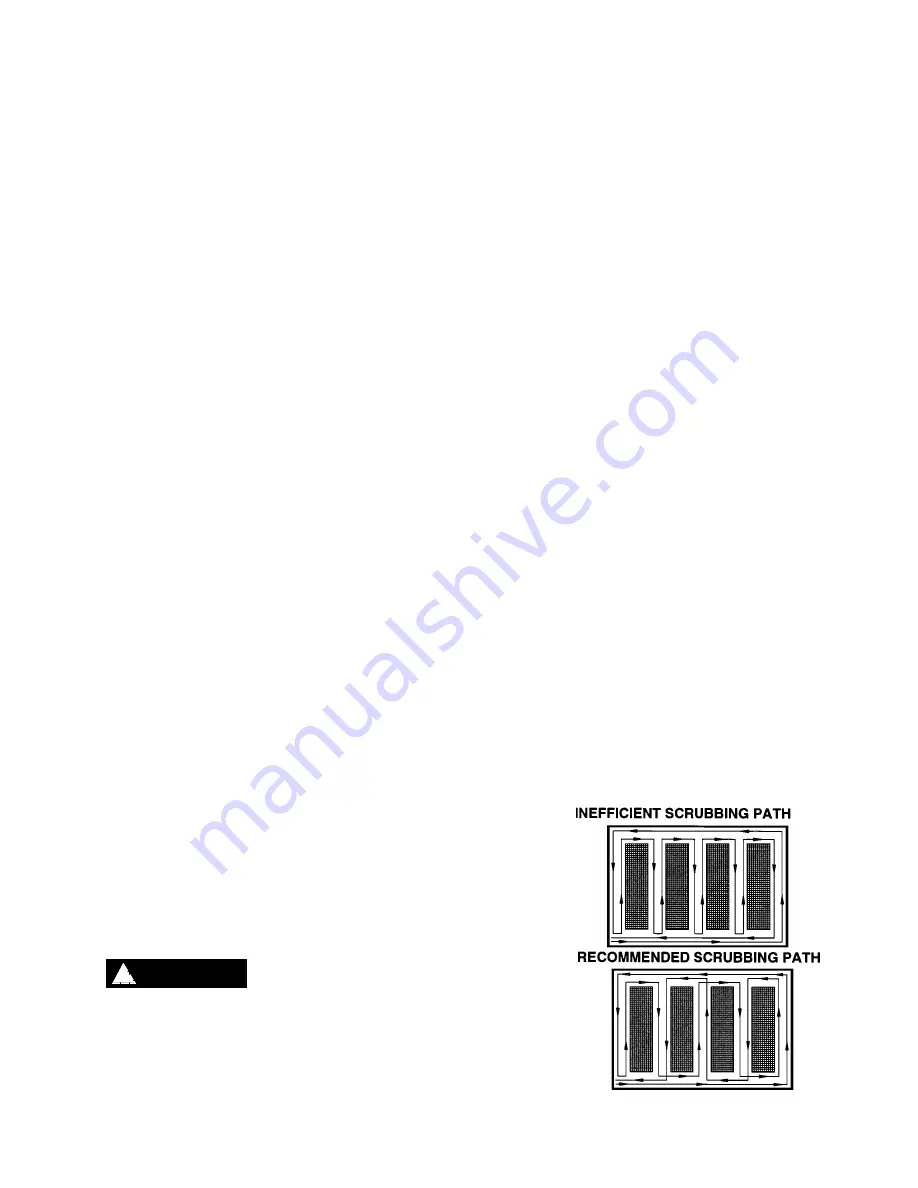

SCRUBBING

Plan the scrubbing pattern in advance. The longest

track is around the perimeter of the area to be

cleaned. For efficient operation, the runs should be

the longest possible without turning, stopping, or

raising or lowering scrub deck/squeegee.

In order to achieve the best possible results, the

area which is to be cleaned should be swept before

scrubbing. Large debris, strings and wire must be

removed to prevent being caught in brushes or

squeegee.

The machine will automatically raise the squeegee

slightly when reverse travel is selected. If the

machine is allowed to stand in neutral with the scrub

deck down for more than 2 seconds, the solutions

flow stops and brush motors stop. If either forward

or reverse travel is selected, the solution flow will

continue in the same setting and the scrub brush

motors will continue in their same setting once

movement of machine begins. Overlap the brush

path and avoid transporting over previously cleaned

areas.