16

Operations

How the Machine Works

This machine is designed and manufactured for

burnishing indoor hard floor surfaces. Kärcher North

America does not recommend use of this machine in

any environment other than an indoor environment.

Battery powered floor equipment is designed and

manufactured for commercial use only. These

machines are designed to burnish most modern types

of floors including composition tile, stone, marble,

terrazzo, and resilient floor covering, and some coated

wood floors.

Operator Responsibility

The operator is responsible for performing the recom-

mended daily maintenance and checkups of the

machine to keep it in good working condition. The

operator must inform the service mechanic or super-

visor when recommended maintenance procedures are

required as prescribed in the MAINTENANCE section

of this manual.

Read this manual carefully before operating this

machine.

FOR SAFETY: Do not operate machine before reading

and understanding the operation manual.

Check the machine for shipping damage.

Keep your machine regularly maintained by following

the maintenance information in this manual. A service

contract for the Lightning BDP 50/2000 W is available

from a Kärcher North America Authorized Distributor or

Service Center.

Order parts and supplies only from an Authorized

Kärcher North America Distributor. Use the parts

illustration section of your manual when ordering parts.

During and after operation, perform the recommended

daily and hourly procedures outlined in the Mainte-

nance Chart.

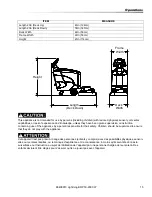

Test for Operator-Ear Sound Pressure

Level

The machine has been measured and rated on the

operator-ear sound pressure level for hand-guided floor

treatment and floor cleaning machines for industrial

use. All tests are performed in accordance with

European Machinery Directive (2006/42/EC).

•

Outdoor test area consists of a flat open space

free from effects of signboards, buildings or

hillsides for at least 15m (50ft) from the center

of the test surface. Indoor tests are conducted

in a semi-anechoic or sound deadening room.

•

The test surface is a single sheet of floor

covering at least 1m (3.3ft) wider and longer

than the equipment being tested. In order to not

affect the sound reading, the observer taking

readings is at least 2m (6.6ft) from the

equipment being tested, or standing directly

behind the operator.

•

All machines are tested while stationary and

centered on the test surface. With the traction

drive in neutral (where applicable) the test is

conducted with the machine at maximum

engine or motor speed as specified by the man-

ufacturer.

•

The operator is located in the normal operating

position with the microphone or meter

supported independent of the machine, 1, 68m

(66in) above the test surface, 25cm (10in) to the

right and left centerline of the operators

position, and 20cm (8in) to the rear most point

of the handle, with the handle in the most

forward position.

•

The sound level meter is observed for a

minimum of 5 seconds or until a stabilized

reading is obtain. The maximum repeatable

sound level observed during the test at each

microphone position is recorded and

documented.

Test for Hand-Arm Vibration at the Grip

Surface of Hand-Guided Machinery

The machine has been measured and rated on the

vibration at the machine-hand contact surface of hand-

guided machines that are provided with handles in

accordance with European Machinery

Directive (2006/42/EC).

•

The test area consists of a flat open floor area

that allows the machine to be operated

normally.

•

The transducer is mounted firmly at a point

halfway along the length of the handle where

the handle would normally be held.

•

Machines are tested while stationary, with all

mechanisms necessary for the equipment to

perform its intended functions engaged and the

traction drive in neutral (if applicable). The

machine will be tested at maximum engine or

motor speed as specified by the manufacturer

of the subject machine.

•

The measurements are recorded from the

dominant axis.

86408910 Lightning BDP 50-2000 W

Summary of Contents for 10020430

Page 23: ...23 Notes 86408910 Lightning BDP 50 2000 W...

Page 32: ...32 Notes 86408910 Lightning BDP 50 2000 W...

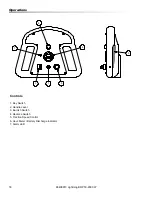

Page 34: ...34 Pad Driver 86408910 Lightning BDP 50 2000 W...

Page 36: ...36 Charger 86408910 Lightning BDP 50 2000 W...

Page 38: ...38 Control Panel 86408910 Lightning BDP 50 2000 W...

Page 40: ...40 Sub Assemblies 86408910 Lightning BDP 50 2000 W...

Page 42: ...42 Wheels 86408910 Lightning BDP 50 2000 W...

Page 44: ...44 Connections 1 86408910 Lightning BDP 50 2000 W...

Page 45: ...45 86408910 Lightning BDP 50 2000 W Connections 1...

Page 47: ...47 86408910 Lightning BDP 50 2000 W Wiring Diagram...