48

Suggested Spare Parts

PART NO.

REF NO.

DESCRIPTION

NOTES

86406560

MP414000

PADHOLDER, 20”, W/ PAD RETAINER

PAD DRIVER

86406950

MP432400

RETAINER, PAD, BLUE

PAD DRIVER

86406800

MP425200

SKIRT, STEEL, 20”, ASM

PAD DRIVER

86406570

MP414100

BAG, DUST, CLOTH

PAD DRIVER

86406580

MP414200

BAG, DUST, PAPER, 3 PACK

PAD DRIVER

86406390

MP139800

SKIRT EDGING - 6FT (183 CM)

PAD DRIVER

86409080

MP265100

115V CHARGER FUSE

CHARGER

86406660

MP415200

GAS SPRING

CHARGER

86406440

MP234700

FUSE, GLASS, 3 AMP1

CONNECTION

86409070

MP223500

BATTERY, 12V, LEAD ACID

CONNECTION

86409090

MP413600

BATTERY, 12V, SEALED

CONNECTION

86409120

MP433200

BRUNISH MOTOR BRUSHES

SUBASSEMBLIES

86409130

MP433300

TRANSAXLE MOTOR BRUSH

WHEELS

86408910 Lightning BDP 50-2000 W

Summary of Contents for 10020430

Page 23: ...23 Notes 86408910 Lightning BDP 50 2000 W...

Page 32: ...32 Notes 86408910 Lightning BDP 50 2000 W...

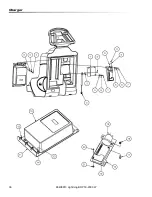

Page 34: ...34 Pad Driver 86408910 Lightning BDP 50 2000 W...

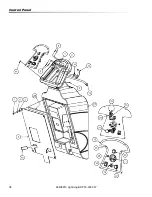

Page 36: ...36 Charger 86408910 Lightning BDP 50 2000 W...

Page 38: ...38 Control Panel 86408910 Lightning BDP 50 2000 W...

Page 40: ...40 Sub Assemblies 86408910 Lightning BDP 50 2000 W...

Page 42: ...42 Wheels 86408910 Lightning BDP 50 2000 W...

Page 44: ...44 Connections 1 86408910 Lightning BDP 50 2000 W...

Page 45: ...45 86408910 Lightning BDP 50 2000 W Connections 1...

Page 47: ...47 86408910 Lightning BDP 50 2000 W Wiring Diagram...