Summary of Contents for 10080480

Page 31: ...31 PARTS 86302100 CLIPPER DUO Parts...

Page 32: ...32 Brush Deck 86302100 CLIPPER DUO...

Page 34: ...34 Brush Deck Motor 86302100 CLIPPER DUO...

Page 40: ...40 Decal 5 1 2 3 4 86302100 CLIPPER DUO...

Page 42: ...42 Hand Tool 1 2 3 4 5 86302100 CLIPPER DUO...

Page 44: ...44 Handle 1 3 5 9 10 2 8 6 7 4 1 1 11 86302100 CLIPPER DUO...

Page 46: ...46 Handle Bracket 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 3 4 10 15 16 17 86302100 CLIPPER DUO...

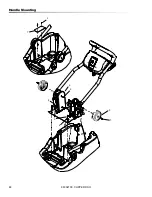

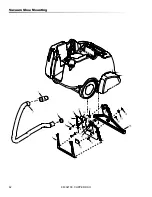

Page 48: ...48 Handle Mounting 1 2 3 4 5 6 7 4 2 86302100 CLIPPER DUO...

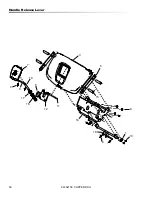

Page 50: ...50 Handle Release Lever 15 16 17 18 4 4 1 2 3 5 6 7 8 9 10 11 12 13 14 86302100 CLIPPER DUO...

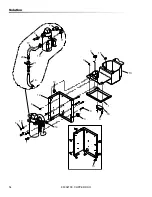

Page 52: ...52 Recovery Tank 1 2 3 4 5 6 7 8 9 10 11 86302100 CLIPPER DUO...

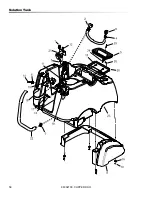

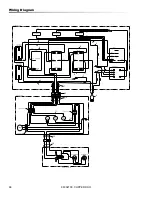

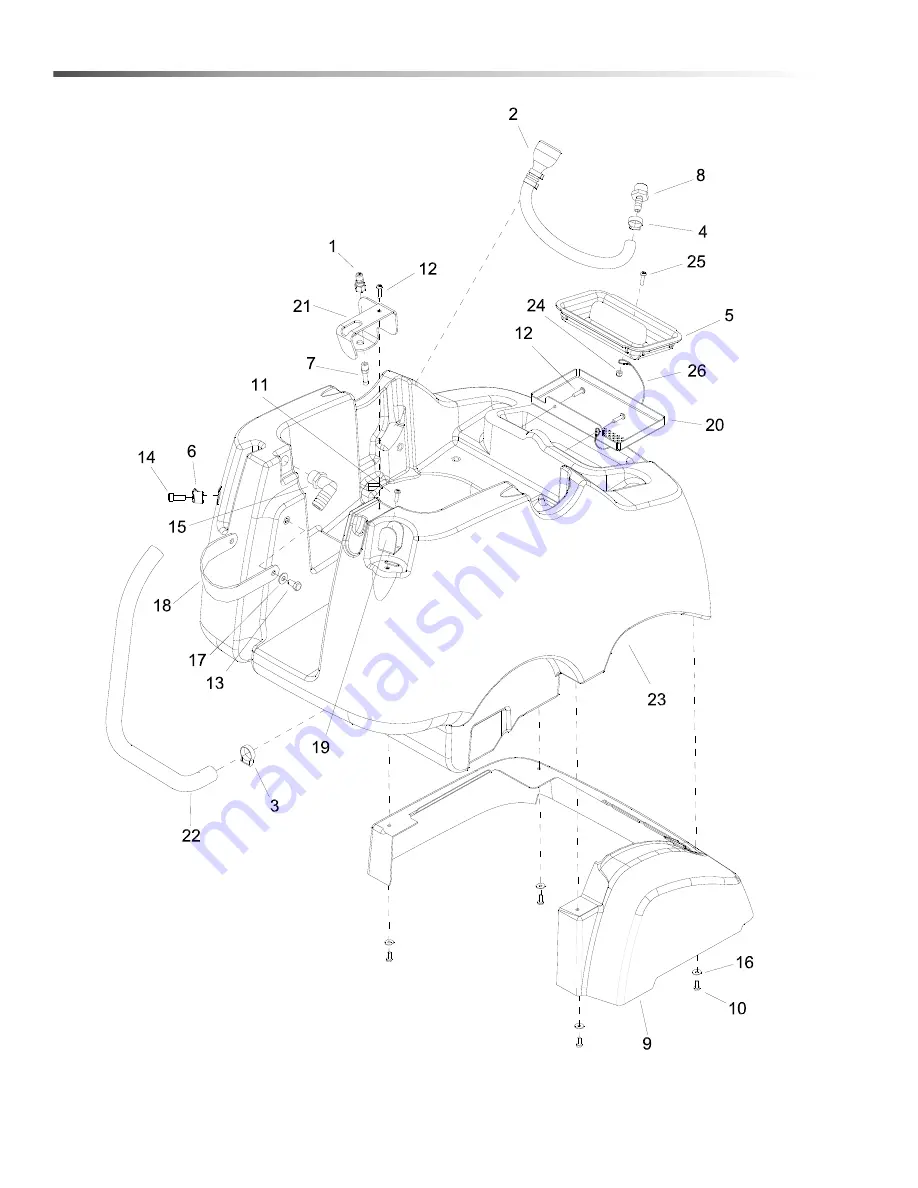

Page 54: ...54 Solution 20 21 18 17 11 4 2 1 3 5 6 7 8 9 10 12 13 14 16 19 14 3 15 15 86302100 CLIPPER DUO...

Page 58: ...58 Solution Tank 86302100 CLIPPER DUO...

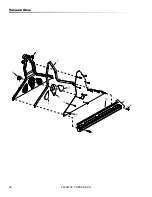

Page 60: ...60 Vacuum Shoe 86302100 CLIPPER DUO...

Page 62: ...62 Vacuum Shoe Mounting 86302100 CLIPPER DUO...

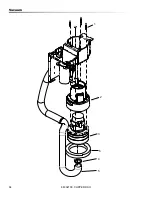

Page 64: ...64 Vacuum 1 2 3 4 5 6 86302100 CLIPPER DUO...

Page 66: ...66 Wheel Axle 1 2 3 4 5 6 7 2 1 86302100 CLIPPER DUO...

Page 72: ...72 Notes 86302100 CLIPPER DUO...