10

Maintenance

Periodic Maintenance

(Every six to twelve months):

1. Check filter for wear, replace dirt saturated filters that do

not respond to normal cleaning.

2. Inspect gasket seals and replace those which have

begun to leak.

3. Examine carbon motor brushes and commutator.

Servicing the Filter

The filter is accessed by lifting the head assembly off the tank.

Polyester filter is easily removed by simply lifting the filter basket out of the tank.

Cartridge filters – Remove the filter retainer by turning the black knob 90 degrees counter-clockwise.

Cartridge filter will then slide off of float assembly.

NOTE: Be sure to frequently clean the filter. Allow filter to dry after being used for wet pick-up. Filters used for wet

pick-up including stripper must be thoroughly cleaned before being allowed to dry. Worn filters can affect vacuum

performance. Replace the filter when it becomes worn out and normal cleaning will not restore vac performance.

Servicing the Vac Motor

Motor Replacement

1. Disconnect power cord from power source.

2. To access the vac motor, remove the screws that attach the main cover to the head assembly and set the cover

to one side.

3. Disconnect the motor ’s 2 red lead wires from the main switch.

4. Disconnect green/yellow wire by removing screw from motor core.

5. Remove the four motor mounting screws.

6. Remove motor plate and set aside.

7. Take out the motor and remove the upper and lower gaskets.

8. Inspect gaskets. If they shown any wear or tear in the material, replace.

9. Install gaskets onto new motor. Make sure gaskets are properly seated.

10. Install the new motor. Make sure foam mufflers are positioned properly.

11. Attach motor plate to motor.

12. Connect green/yellow wire to motor core.

13. Connect motor ’s 2 red lead wires to main switch.

14. Re-assemble vac cover.

15. Test for proper operation.

86369590 Titan Vacuum

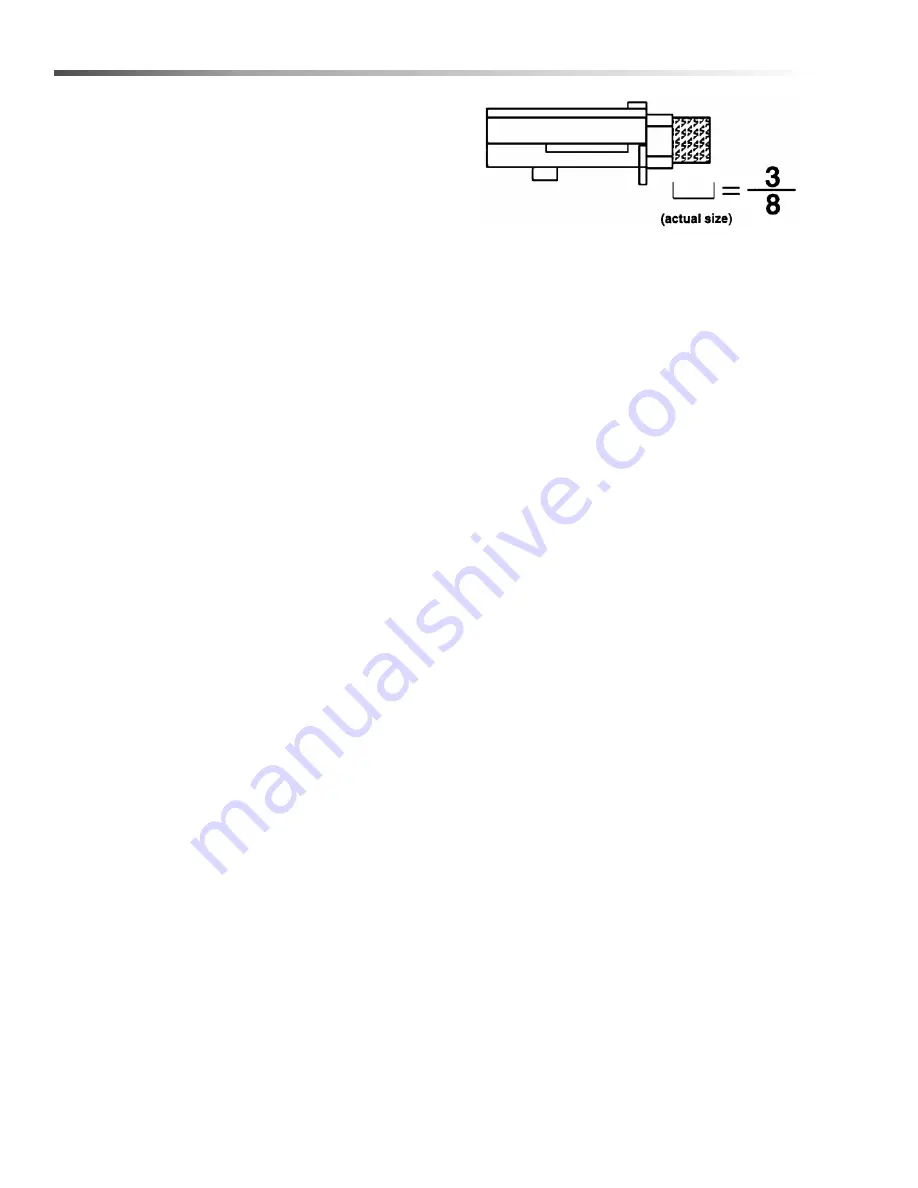

Replace both carbon brushes when either is less

than 3/8" long.

(P/N 8.616-352.0) 120V, (P/N 8.616-353.0) 230V

Summary of Contents for 10130060

Page 12: ...12 86369590 Titan Vacuum Notes ...

Page 13: ...13 PARTS 86369590 Titan Vacuum Parts ...

Page 14: ...14 Vacuum Motor Assembly T708 T708IE 86369590 Titan Vacuum ...

Page 16: ...16 Vacuum Motor Assembly 86369590 Titan Vacuum ...

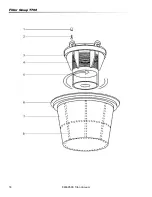

Page 18: ...18 Filter Group T708 86369590 Titan Vacuum ...

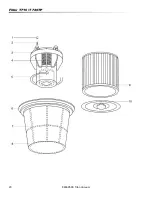

Page 20: ...20 Filter T716 T720TP 86369590 Titan Vacuum ...

Page 22: ...22 Tank T708 86369590 Titan Vacuum ...

Page 24: ...24 Tank T716 86369590 Titan Vacuum ...

Page 26: ...26 Tank and Cart T720TP 86369590 Titan Vacuum ...

Page 28: ...28 Front Mounted Squeegee TSQ16 86369590 Titan Vacuum ...

Page 30: ...30 Front Mounted Squeegee TSQ20 86369590 Titan Vacuum ...