52

86333220 CS20

Maintenance

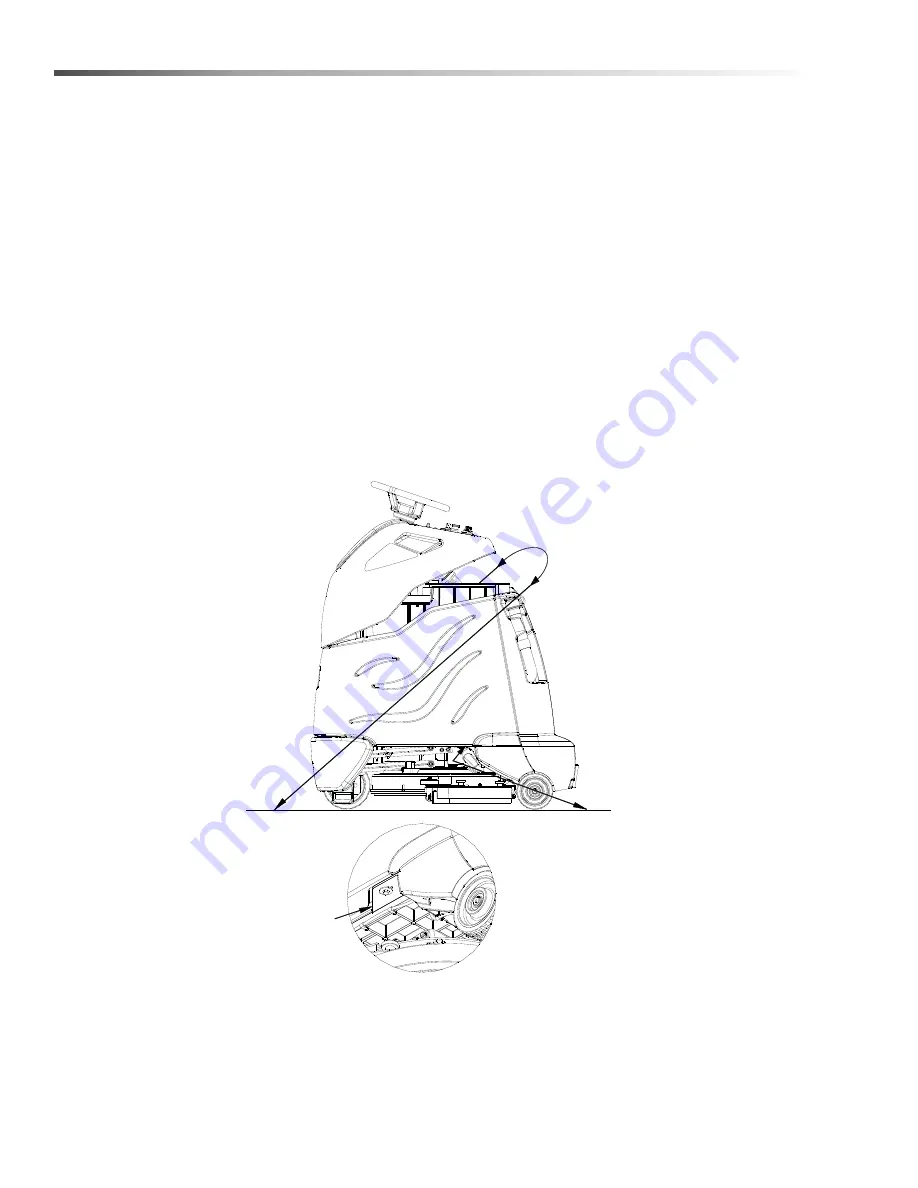

Preparation for Loading/Unloading Trailer

Before loading or unloading machine from trailer, remove squeegee and scrub brush (pad) to eliminate interference

with ramp.

Scrub head must be in the up position before loading.

When transporting the machine on a trailer or in a truck, in addition to using tie-downs, be sure to block the tires to

prevent the machine from rolling.

Machine Tie-Downs

There are two tie points located in front of the rear wheels on the frame, and a Tie-down wrap point on the recovery

tank. Tie-down devices must be of the proper type and strength. The combined strength of all tie-downs must be

strong enough to lift two times the weight of the machine. Tie-downs must be positioned to prevent the machine

from moving forward, backward, or either side to side. Use all four corners of the machine with the tie-downs

running out opposite directions. Tie-downs must be attached to the transporting vehicle securely.

CONNECT

AT

FRAME

VIEW FROM

BOTTOM

Recommended Tie-Down Points

Summary of Contents for chariot iScrub 20 CS20

Page 14: ...14 86333220 CS20 Operations Drive Controls 1 2 3 4 5 6 7 8 9 10...

Page 57: ...86333220 CS20 Parts...

Page 58: ...58 86333220 CS20 Bumper 1 2 5 6 3 4 3 7...

Page 60: ...60 86333220 CS20 Bumper Deluxe Cylindrical 1 2 5 6 3 4 3 7 5 3 4 8...

Page 66: ...66 86333220 CS20 Control Panel 2 17 9 16 3B 15 14 13 12 11 10 9 8 7 6 5 4 2 1 3A...

Page 68: ...68 86333220 CS20 Decals Disk 6 5 1 2 3 4...

Page 70: ...70 86333220 CS20 Decals Deluxe Cylindrical 2 1 3A 3A 4 3B 3B...

Page 76: ...76 86333220 CS20 Drive Mounting 1 2 3 4 5 6 7 4 7...

Page 78: ...78 86333220 CS20 Frame Rear Wheels 1 2 3 4 5 6 7 8 9...

Page 80: ...80 86333220 CS20 On Board Battery Charger Disk 6 8 1 2 15 3 4 5 6 7 9 10 11 13 14 7 6 10 12 8...

Page 84: ...84 86333220 CS20 Pedal Platform 3 4 5 6 7 8 9 10 11 1 2 2 2 2...

Page 86: ...86 86333220 CS20 Pedal Platform Mounting...

Page 90: ...90 86333220 CS20 Scrub Brush Pad Driver 8 4 9 6 5 7 5 3 2C 2A 2B 7 5 8 4 9 6 1 10A 10F...

Page 94: ...94 86333220 CS20 Scrub Brush Deck Mounting Disk 1 2 3 4 5 6...

Page 98: ...98 86333220 CS20 Scrub Deck Cylindrical...

Page 102: ...102 86333220 CS20 Scrub Brush Deck Mounting Cylindrical 1 2 3 4 8 7 6 5 9 10 11...

Page 104: ...104 86333220 CS20 Scrub Deck Lift 1 2 3 4A 5 6 7 8 12 7 10 9 11 A TORQUE 50 IN OZ A 13 4B...

Page 114: ...114 86333220 CS20 Squeegee Linkage Cylindrical 1 2 3 4 5 6 7 8 9 10 11 12 13 14 16 15 17 18 19...

Page 116: ...116 86333220 CS20 Steering 4 5B 1B 2 6B 7 1A 2 3 4 5A 6A...

Page 118: ...118 86333220 CS20 Vacuum 1 2 3 4 5 6 7 8 See maintenance section for motor mounting details...

Page 120: ...120 86333220 CS20 Wiring Battery 1A 2A 3 4 5 MAIN WIRING HARNESS 6 1B 2B...