COMMODORE 1

1

53118

53119 Motor

65070)

2

67071

3

47075

47076

Kit,

Plate

(for

65067)

12-13

and

10

27225

14

41088

15A

65071

(for

65067)

65072 Pump

(for

650701

SOLID STATE CONTROL

BOARD (DC CIRCUIT)

The

Control Board converts

nating current (AC) to direct current

(DC) for the traverse drive motor and

clutch solenoid.

A 2 amp

ceramic fuse is

in-

stalled

in

the motor circuit to protect

the circuit

board

and motor

in

the event

an overload condition occurs.

NOTE:

Always use the same type and

size fuse for replacement.

DRIVE

MOTOR

DOES

W

1.

Check continuity (use ohmmeter) of

cord, drive motor switch, and

slow-blow fuse.

If fuse blows after replacing, check

for short circuit in system or faulty

motor. If this does not correct prob-

lem the PC Control Board may be

faulty.

NOT

RUN,

CHECK THE

To test voltage at

Control

Board:

Aug power cord into properly grounded

and press on drive motor switch,

Use AC volt meter to check Input volt-

age at terminals AC and AC on PC

Board. Voltage should be

(on

11

5 volt

models) and 230V (on 230 volt

models). Use DC

meter to check

DC

output

voltage at terminals A+

and A-. With the speed control knob

set at MAX

(4)

DC volts should be 95

VDC

10%.

if there is "0" voltage

or the voltage does not remain constant,

this is an indication that the circuit

board is faulty. Replace as required.

TO

TEST

MOTOR:

To test for

or

first

disconnect machine

source

each

If

are

tinuity),

is

To

check for shorted armature, use

ohmmeter to measure the resistance

between the motor

if resistance

is 5 ohms or less, the armature is

short circuited; replace gear motor.

CLUTCH

NOT

CHECK THE

WINO:

NOTE:

A

1

amp fast blow fuse is in-

stalled

in

the clutch actuator circuit to

protect the PC Control Board in the

event an overload condition occurs.

The fuse is located in-line near the

clutch actuator

1.

Check clutch switch (use ohmmeter)

for continuity.

2.

Check in-line 1 amp fuse. If fuse

blows after replacing, the coil is

faulty. Replace as required.

3.

Use a DC

meter

to

check DC

voltage to

coil at terminals

and

F-

on Control Board. The DC

voltage

be 95 VDC

10%.

there is "0" or iow voltage or if

the voltage does not remain constant,

the circuit board is faulty. Replace

as required.

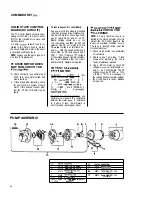

PUMP ASSEMBLY

15

14

12

9

8

7

1

2

15

10

Summary of Contents for COMMODORE CMD

Page 11: ...COMMODORE 115V CONTROL PANEL ASSEMBLY I COMMOOOAE CONTROL PANEL ...

Page 12: ...2 CHASSISWIDRIVE ASSEMBLY ...

Page 14: ...COMMODORE 1 15V 14 ...

Page 16: ...COMMODORE 115V SQtUTION RECOVERY TANKS 16 ...

Page 18: ...COMMODORE 115V CONTROL PANE1 WIRING DIAGRAM 230VOLT CHASSIS WIRING DIAORAM 230 VOLT A I8 i 18 ...